A preparation method of carbon nanotube-loaded double metal oxide hollow nanoparticles

A double metal oxide and carbon nanotube technology, applied in the direction of nanotechnology, nanotechnology, nickel oxide/nickel hydroxide, etc., can solve the problem of affecting the purity of the hollow structure, large size of the hollow structure, difficult double metal oxide hollow structure materials and other problems, to achieve good thermal stability, increase the specific surface area, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

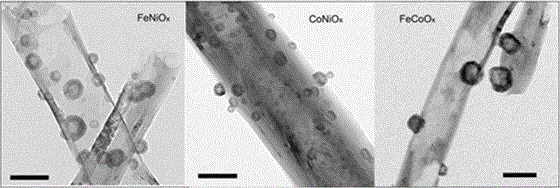

[0029] Carbon nanotube supported FeNiO x Preparation method of hollow nanoparticles

[0030] A. Disperse 5g of carbon nanotubes in 50ml of concentrated nitric acid, and reflux at 140°C for 2h to pretreat the surface of the carbon nanotubes;

[0031] B. Weigh 2mmolFe(NO 3 ) 3 , 2mmolNi(NO 3 ) 2 Dissolve in absolute ethanol; disperse 20 mmol of the surface-pretreated carbon nanotubes obtained in step A in an ethanol solution, ultrasonically, disperse, and stir until the solvent is completely volatilized to obtain a dry solid;

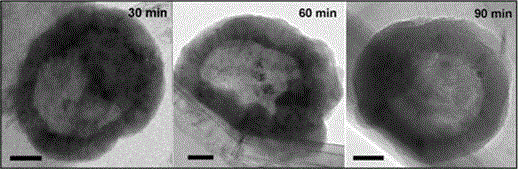

[0032] C. Preheat the dry solid obtained in step B under a nitrogen atmosphere. The preheating temperature is 120° C., and the holding time is 2 hours; 650℃, keep warm for 2h;

[0033] D. Oxidize the material obtained in step C in an air atmosphere, the oxidation temperature is 400°C, the heating rate is 3°C / min, and the temperature is kept for 2h, and then FeNiO supported by carbon nanotubes can be obtained x Double metal oxide hollow nanoparticle...

Embodiment 2

[0035] Carbon nanotube supported FeCoO x Preparation method of hollow nanoparticles

[0036] A. Disperse 5 g of carbon nanotubes in 50 ml of concentrated nitric acid, and reflux for 2 hours at 140° C. for pre-surface treatment of carbon nanotubes;

[0037] B. Weigh 2mmolFe(NO 3 ) 3 , 2mmolCo(NO 3 ) 2 Dissolve in absolute ethanol; disperse 20 mmol of the surface-pretreated carbon nanotubes obtained in step A in an ethanol solution, ultrasonically, disperse, and stir until the solvent is completely volatilized to obtain a dry solid;

[0038] C. Preheat the dry solid obtained in step B under a nitrogen atmosphere. The preheating temperature is 120° C., and the holding time is 2 hours; 650℃, keep warm for 2h;

[0039] D. Oxidize the material obtained in step C in an air atmosphere, the oxidation temperature is 400°C, the heating rate is 3°C / min, and the temperature is kept for 2h, and then FeCoO supported by carbon nanotubes can be obtained x Double metal oxide hollow nanop...

Embodiment 3

[0041] Carbon nanotube supported NiCoOx Preparation method of hollow nanoparticles

[0042] A. Disperse 5 g of carbon nanotubes in 50 ml of concentrated nitric acid, and reflux for 2 hours at 140° C. for pre-surface treatment of carbon nanotubes;

[0043] B. Weigh 1.33mmolNi(NO 3 ) 2 , 2.66mmolCo(NO 3 ) 2 Dissolve in absolute ethanol; disperse 20 mmol of the surface-pretreated carbon nanotubes obtained in step A in an ethanol solution, ultrasonically, disperse, and stir until the solvent is completely volatilized to obtain a dry solid;

[0044] C. Preheat the dry solid obtained in step B under a nitrogen atmosphere. The preheating temperature is 120° C., and the holding time is 2 hours; 650℃, keep warm for 2h;

[0045] D. Oxidize the material obtained in step C in an air atmosphere, the oxidation temperature is 400°C, the heating rate is 3°C / min, and the temperature is kept for 2h, and then NiCoO supported by carbon nanotubes can be obtained x Double metal oxide hollow n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com