Preparation method of defect-rich titanium dioxide graphene composite nanophotocatalyst and carbon nanotube graphene composite carbon material

A nano-photocatalyst and graphene composite technology, applied in the direction of titanium dioxide, carbon nanotubes, multi-walled carbon nanotubes, etc., can solve the problems of poor water solubility of carbon nanotubes, limited application range, and easy agglomeration, etc., reaching TiO2 nanometer The effect of small particle size, expanded application range, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

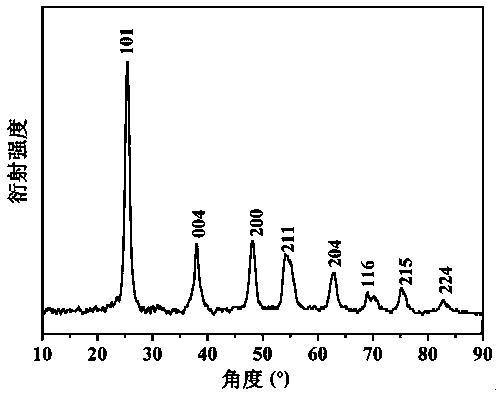

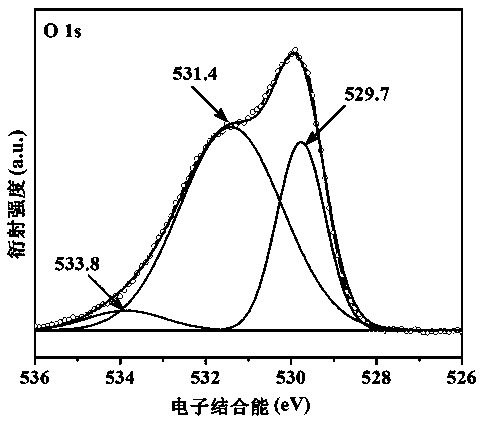

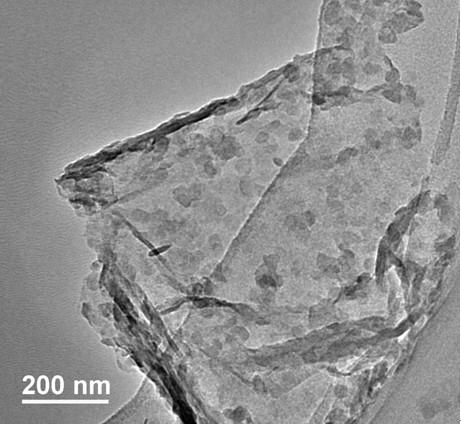

[0031] A preparation method of a titanium dioxide / graphene composite nano photocatalyst rich in defect sites, comprising the following steps:

[0032] A, using graphite as a raw material, adopting the Hummer method to prepare graphene oxide, and ultrasonically dispersing the prepared graphene oxide into an alcohol solution to obtain a graphene oxide suspension;

[0033] B, the titanium source is dispersed in the graphene oxide suspension obtained in step A, and the graphene oxide suspension containing the titanium source is obtained;

[0034] C, configure precipitant alcohol aqueous solution;

[0035] D. Add the precipitant alcohol aqueous solution obtained in step C dropwise to the graphene oxide suspension containing titanium source obtained in step B under stirring conditions;

[0036] E. Transfer the suspension obtained in step D into a polytetrafluoroethylene liner, heat it to 120 ° C ~ 220 ° C after airtight, after reacting for 3 h ~ 24 h, naturally cool to room temperatu...

Embodiment 1

[0048] Accurately weigh 0.1 g of graphene oxide prepared by the Hummer method and ultrasonically disperse it in 100 mL of methanol solution to form suspension A; Form suspension B in 1 minute, the concentration of titanium tetrachloride in suspension B is 0.0364 M; Another configuration 50 mL concentration is the sodium borohydride solution of 0.292 M, under the stirring condition of 500 rev / mins, obtain in step C The alcoholic aqueous solution containing sodium borohydride was added dropwise in the suspension B, and after the dropwise addition was completed, it was transferred to a polytetrafluoroethylene liner, and reacted for 24 hours under solvothermal conditions at 160 ° C, and naturally cooled after the reaction to room temperature, suction filtration and washing to obtain a titanium dioxide / graphene composite nanocatalyst.

[0049] Accurately weigh 0.2 g of defect-rich titanium dioxide / graphene nanocatalyst and evenly spread it on the bottom of the magnetic boat, and pl...

Embodiment 2

[0051] Accurately weigh 0.1 g of graphene oxide prepared by the Hummer method and ultrasonically disperse it in 100 mL of ethanol solution to form suspension A; Form suspension B in 1 minute, the concentration of titanium tetrachloride in suspension B is 0.0182 M; Another configuration 50 mL concentration is the sodium borohydride solution of 0.146 M, under the agitation condition of 1000 rev / mins, obtain in step C The aqueous alcohol solution containing sodium borohydride was added dropwise in the suspension B, and after the dropwise addition was completed, it was transferred to a polytetrafluoroethylene liner, and reacted for 12 hours under solvothermal conditions at 180 ° C, and cooled naturally after the reaction to room temperature, suction filtration and washing to obtain a titanium dioxide / graphene composite nanocatalyst.

[0052] Accurately weigh 0.2 g of defect-rich titanium dioxide / graphene nanocatalyst and evenly spread it on the bottom of the magnetic boat, and pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com