A shaft kiln with internal circulation of fine-grained lime and its calcining method

A fine particle and internal circulation technology, which is applied in the field of lime production equipment, can solve the problems of incomplete combustion of fuel, difficulty in burning materials, and insufficient oxygen supply for combustion, and achieve the effects of saving heat energy, small heat loss, and automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

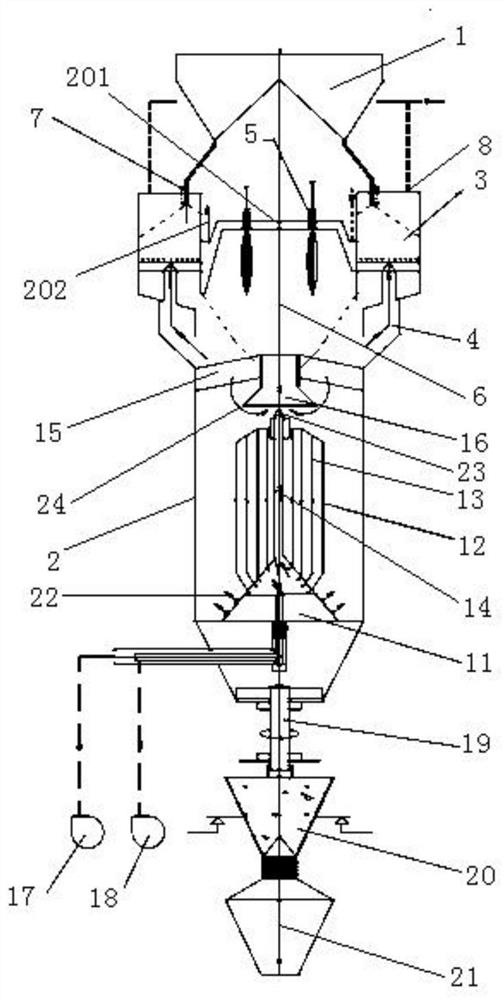

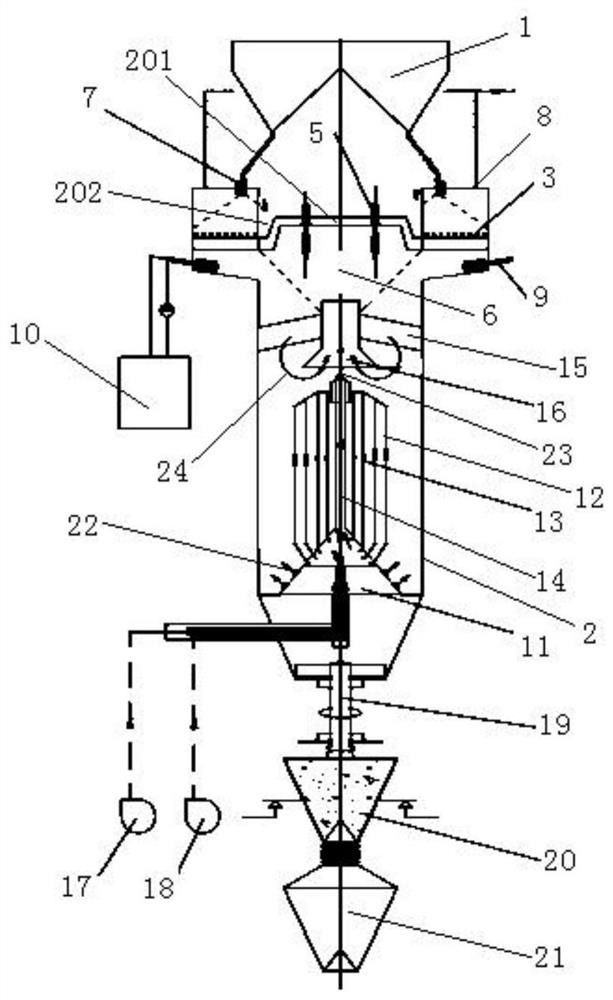

[0041] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] A shaft kiln for fine-grained lime with internal circulation, including a hopper 1, an adjustable lifting and lowering pipe 7, a shaft kiln body 2, an annular preheating chamber 3, a multi-burner combustion chamber 6, an injector 16, a hollow cross beam 15, Built-in heat exchanger 12, bottom air seat 11, cooling blower 17, driving blower 18, ash discharge machine 19, metering bin 20, storage bin 21, the feed bin 1 is located above the kiln roof 201 of the shaft kiln body 2, and the A burner 5 is provided on the kiln roof 201, and the opening of the burner 5 faces downward. Between the bottom of the burner 5 and the hollow cross beam 15 is a multi-burner combustion chamber 6; the annular preheating chamber 3 burns around the multi-burner Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com