Method for preparing aluminum-silicon powder from high-aluminum coal

An aluminum-silicon powder and high-aluminum technology, applied in the field of coal resource utilization, can solve the problems of difficult extraction, high carbon content in ash, poor uniformity of alumina crystal structure, etc., and achieves reduction of carbon content, high thermal efficiency, and increased retention effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

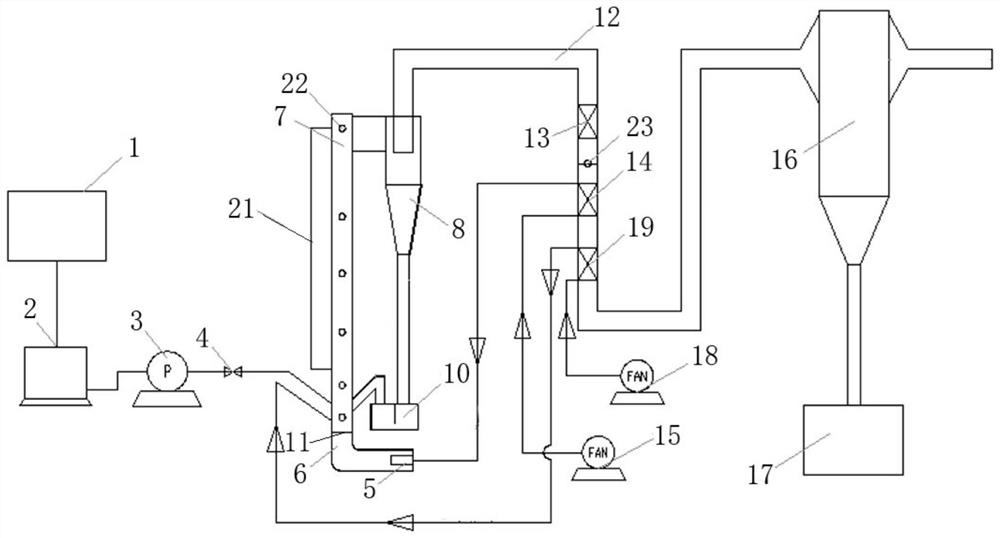

Image

Examples

Embodiment

[0045] The coal water slurry parameters are as follows: raw coal particle size <180μm, raw coal content 68%, moisture content 31%, additive content 1%, calorific value controlled at 3100kCal / kg;

[0046] At the start-up stage, circulating ash with a thickness of 500 mm was added to the air distribution plate of the decarbonization reactor as the start-up bed material, and natural gas was used as the auxiliary fuel for ignition. The amount of coal-water slurry fed can be fed according to 30% of the full-load design working condition. The oxygen content drops significantly, and the coal-water slurry is successfully ignited. Then, gradually increase the amount of slurry fed to increase the temperature of the decarburization reactor.

[0047] When the overall temperature level inside the decarburization reactor reaches 720°C, gradually reduce the amount of auxiliary fuel, observe the temperature change in the decarbonization reactor during the process, and the internal temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com