A heat vulcanizing adhesive

A heat-vulcanized adhesive and adhesive technology, which is applied in the direction of adhesives, adhesive additives, halogen rubber derivative adhesives, etc., can solve problems such as the bonding failure of the primer adhesive and the interface layer of the steel plate, and achieve a solution Difficulty, improve toughness, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

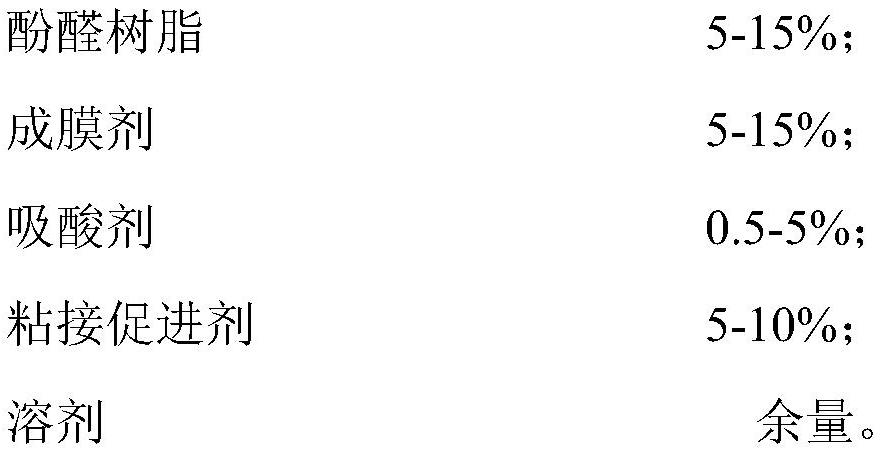

[0049]Embodiment 1 of the present invention provides a thermal vulcanized adhesive, calculated by weight, including:

[0050]

[0051]The relative molecular mass of the phenolic resin is 900 to 1000; the phenolic resin is 3201 phenolic resin, purchased from the Fengze gel industry;

[0052]The film film is a chlorinated natural rubber;

[0053]The acidic acid is zinc oxide;

[0054]The solvent is methyl isobutyl ketone;

[0055]The adhesive promoter is a porous inorganic filler supported a liquid nitrile rubber, wherein the porous inorganic filler medium in the porous inorganic filler support is zirconia; the porous inorganic filler support The reaction type liquid nitrile rubber in the reactive liquid nitrile rubber is an endocyclic oxycitrite nitrile rubber, purchased from Beijing Twurt Chemical Co., Ltd., and the grade CHX100.

[0056]The preparation process of the porous inorganic filler supported liquid nitrile rubber is: 4 hours in a 30% silane coupling agent / acetone solution of zirconia in 60 °...

Embodiment 2

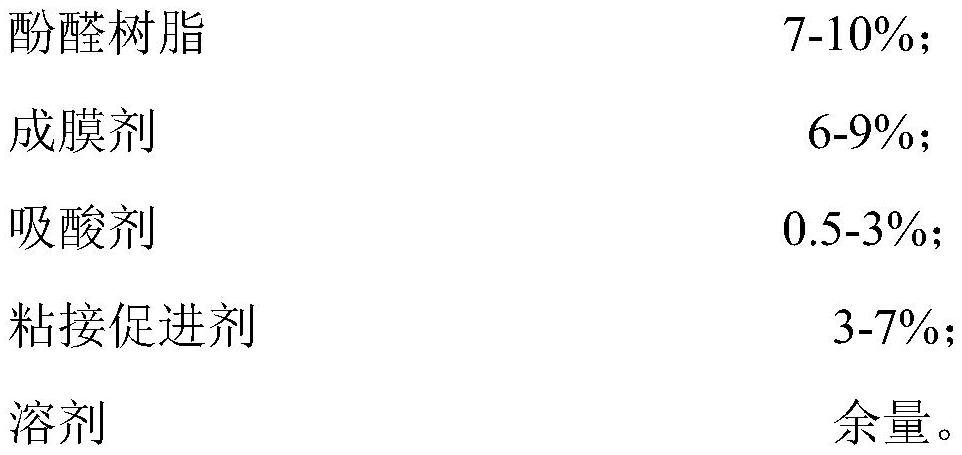

[0059]The embodiment of the second embodiment of the present invention is in Example 1, and the thermal vulcanized adhesive comprises: calculated by weight percentage

[0060]

Embodiment 3

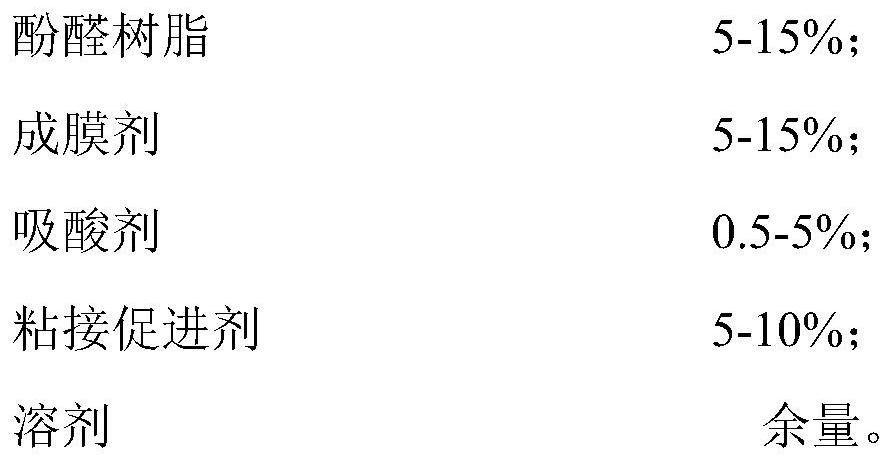

[0062]The embodiment of the third embodiment of the present invention is in Example 1, and the thermal vulcanized adhesive comprises:

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com