Device and method for testing proppant laying of API flow guiding chamber

A test method and proppant technology, which are applied in the directions of surveying, earthwork drilling, wellbore/well components, etc., can solve the problems such as the large error of experimental data affecting the experimental results, and achieve the effect of ensuring accuracy and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

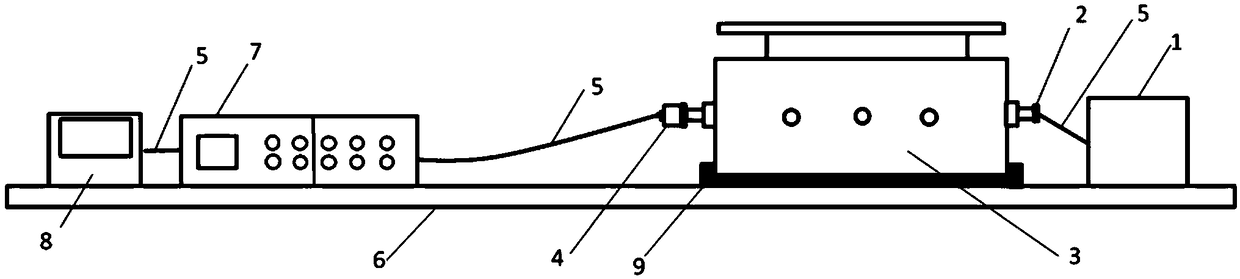

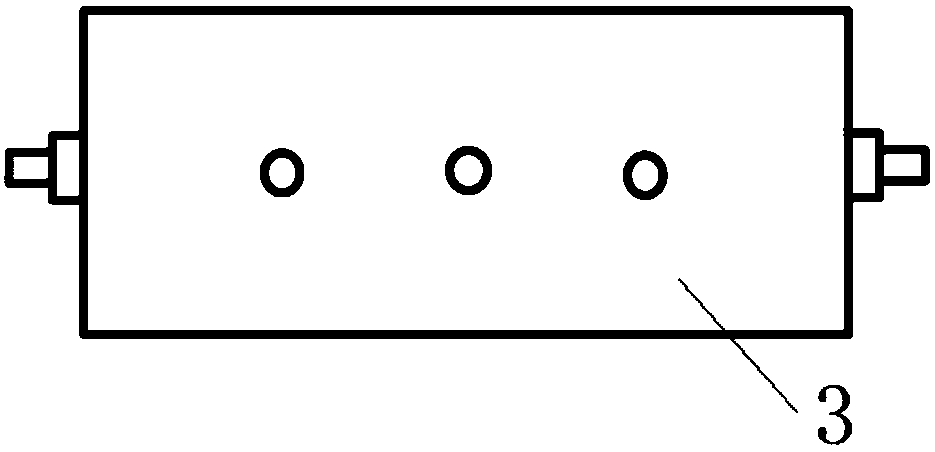

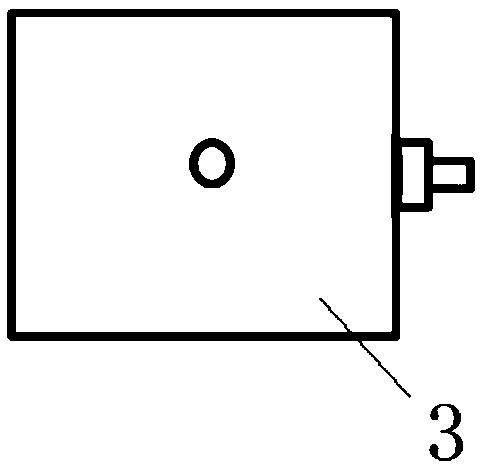

[0046] The implementation process of this embodiment is: reference Figure 1 to Figure 9 , the diversion chamber 3 is installed on the horizontal workbench 6, after laying a circle of 2 mm thick organic silicon film 10 in the diversion chamber 3, a one-centimeter thick proppant 11 is laid on the organic silicon film 10, and the The diversion chamber 3 slowly presses the diversion chamber 3 into the rubber base 9 and fixes it firmly. Use plasticine to glue the probe 2 and the outlet of the diversion chamber 3, then glue the signal receiving end of the piezoelectric sensor 4 and the inlet of the diversion chamber 3 together with plasticine, and tap it lightly with a rubber hammer Hit the diversion chamber 3 to observe whether the probe 2 and the piezoelectric sensor 4 will fall off, if not, it proves that the bonding is completed, otherwise, re-bond. After bonding, use the data line 5 to connect the other end of the piezoelectric sensor 4 to the input of the data analyzer 7 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com