Method for prolonging service life of LED lamp

A technology of LED lamps and LED chips, which is applied to semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, lighting devices, etc. Improves heat dissipation, accelerates cooling, and delays reflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

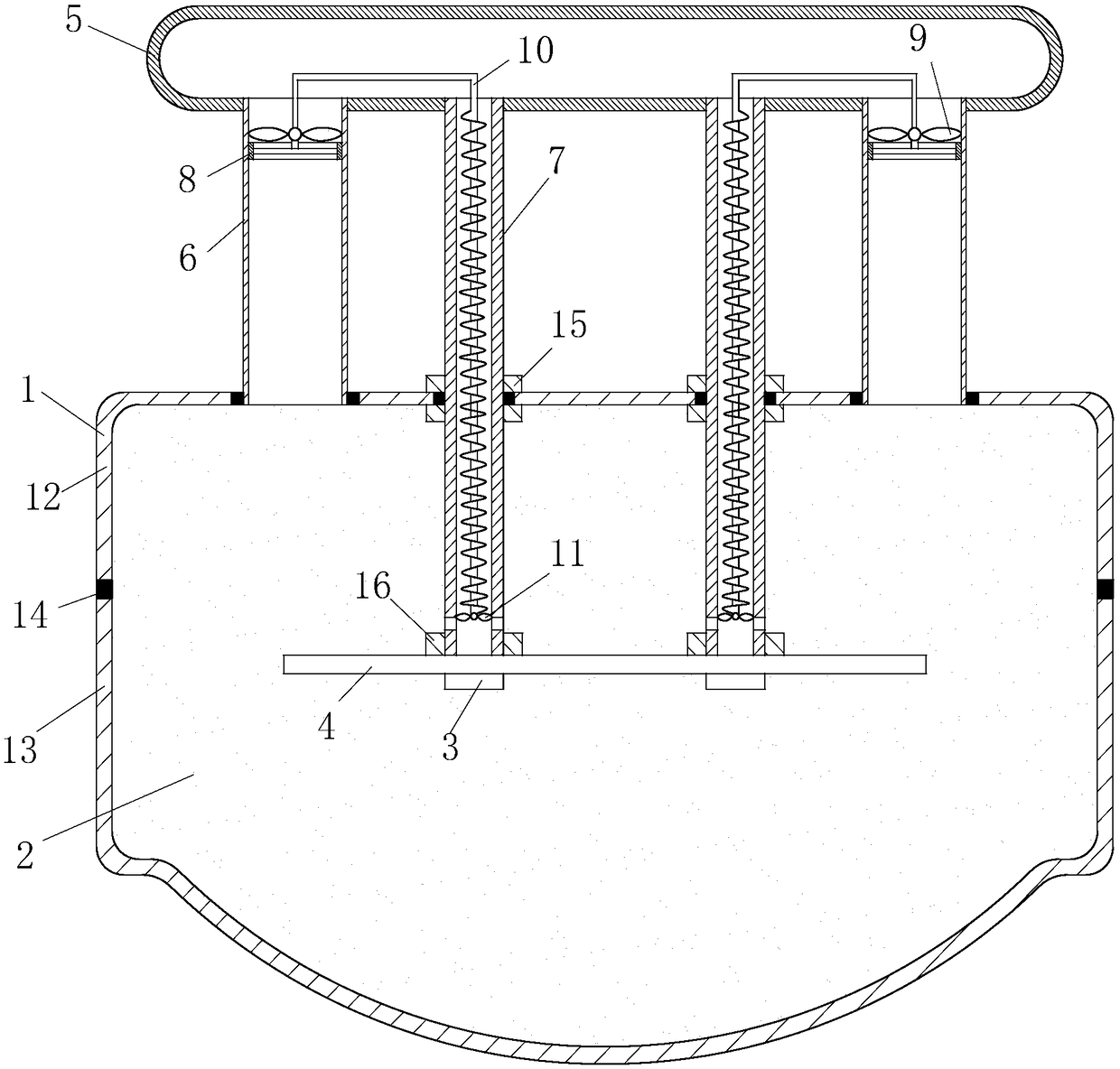

[0025] As an embodiment of the present invention, the wrapping arrangement wraps the heater on the outer wall of the air outlet pipe 6, which can achieve a sufficient heating effect and achieve the purpose of accelerating the operation of the cooling system of the lamp; There is a gap between 6 to prevent the temperature of the heater from being too high to cause the outlet pipe 6 to rupture; the half-side setting sets the heater on the side of the outlet pipe 6 away from the return pipe 7 to prevent the temperature of the heater from affecting the cooling and returning heat transfer fluid 2.

[0026] As an embodiment of the present invention, the upper vitreous body 12 and the lower vitreous body 13 are seamlessly fixedly connected by a sealant 14; the air outlet pipe 6 and the upper vitreous body 12 are seamlessly fixedly connected by a sealant 14; The backflow pipe 7 and the upper vitreous body 12 are seamlessly connected by a sealant 14; the fixed ring 8 is an interference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com