Performance detection system of electric automobile hub motor

A technology for in-wheel motors and electric vehicles, which is applied in motor-generator testing, electrical measurement, and measurement devices, etc., can solve problems such as hindering the optimization and improvement of in-wheel motor technology, low accuracy of performance test data, and potential safety hazards, and achieves easy promotion, Good fixed, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

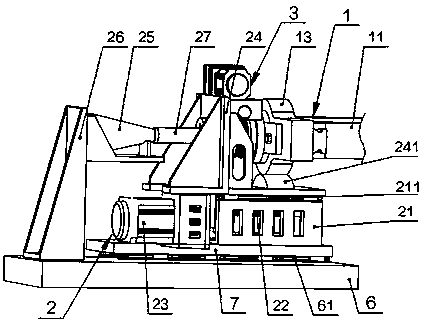

[0039] The patent of the present invention will be further specifically described below in conjunction with the accompanying drawings.

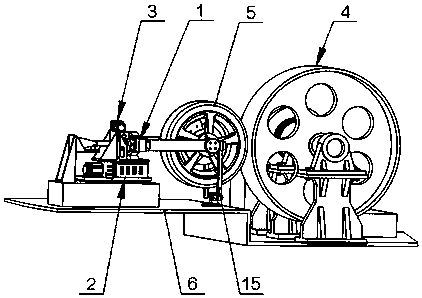

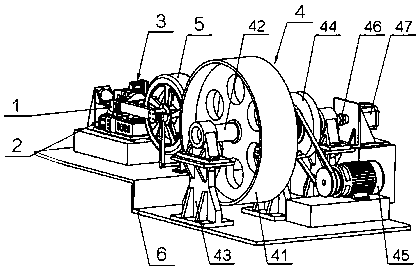

[0040] like Figure 1-4 As shown, a performance detection system for an electric vehicle hub motor includes a wheel connecting frame mechanism 1, a vertical loading mechanism 2, a lateral loading mechanism 3 and a drum dynamometer mechanism 4;

[0041] One end of the wheel connecting frame mechanism 1 is fixedly connected to the wheel 5, and the vertical loading mechanism 2 and the lateral loading mechanism 3 are connected to the other end of the wheel connecting frame mechanism 1;

[0042] The vertical loading mechanism 2 is used to drive the wheel fixing frame mechanism 1 and vertically load the wheels 5;

[0043] The lateral loading mechanism 3 is used to drive the wheel fixing frame mechanism 1 and laterally load the wheels 5;

[0044] The drum 41 of the drum dynamometer 4 is in contact with the wheel 5 , and the drum dynamometer 4 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com