A propeller static strength calculation method

A calculation method and technology for propellers, applied in the direction of calculation, computer-aided design, design optimization/simulation, etc., can solve problems such as insufficient interface stability, unfavorable propeller design, complex modeling, meshing process, etc., to improve design efficiency , the effect of high calculation efficiency and simple implementation program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

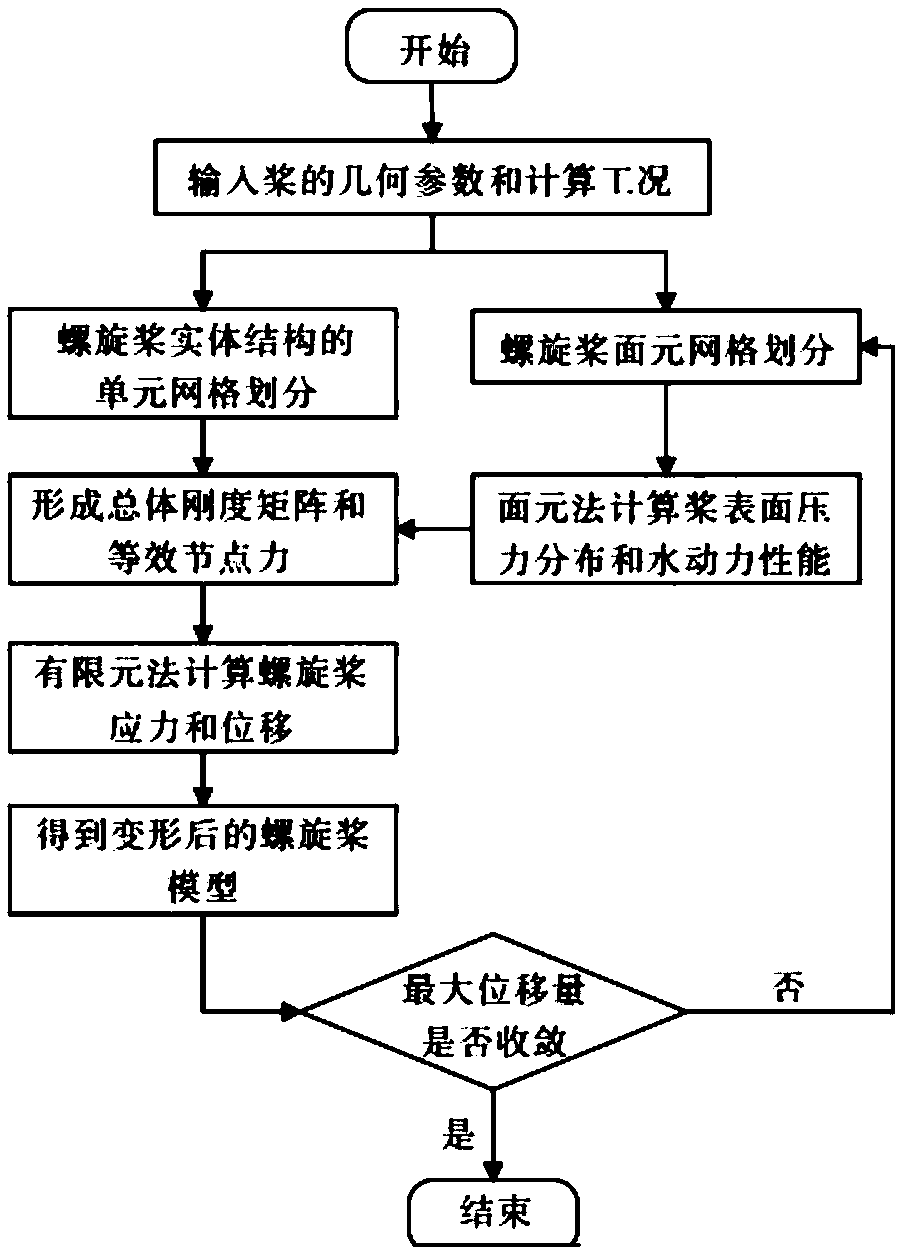

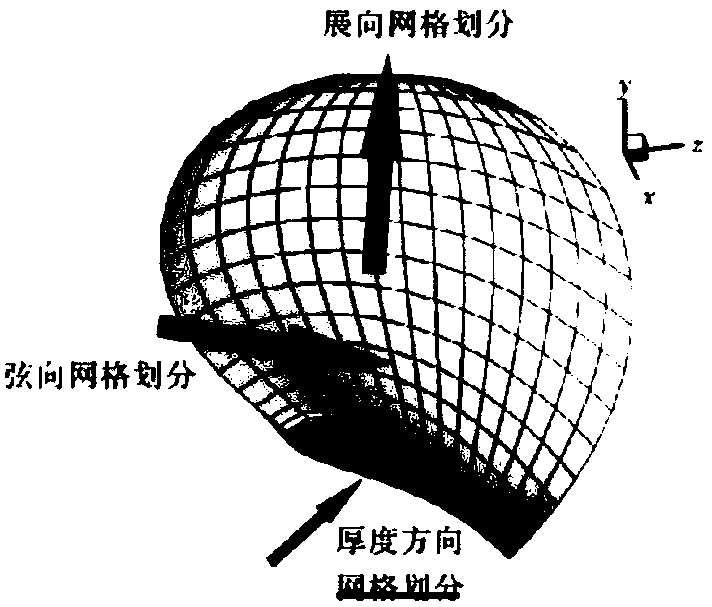

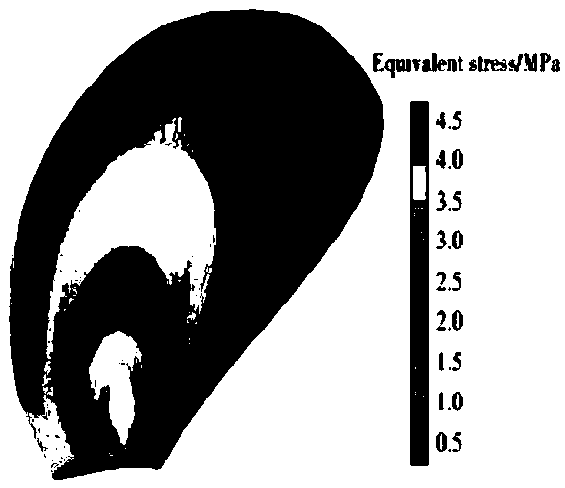

[0036] A propeller static strength calculation method adopts the combination of surface element method and finite element method to calculate the propeller static strength, which has the advantages of high efficiency and accurate calculation results. First, the propeller to be calculated is divided into panel meshes and unit meshes of the solid structure, and the overall stiffness matrix and equivalent nodal force are formed after meshing, and then the surface element method is used to calculate the surface pressure distribution and hydrodynamic performance of the propeller , using the finite element method to calculate the propeller stress and displacement, so that the deformed propeller model can be obtained. Finally, iterative calculation is carried out, and the final propeller static strength calculation result is calculated by judging whether the maximum displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com