A workpiece burr detection method based on image processing

A technology of image processing and detection method, which is applied in the detection field, can solve the problems of consuming a lot of time and slow measurement speed, and achieve the effect of improving detection accuracy, low requirements, and simple measurement system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

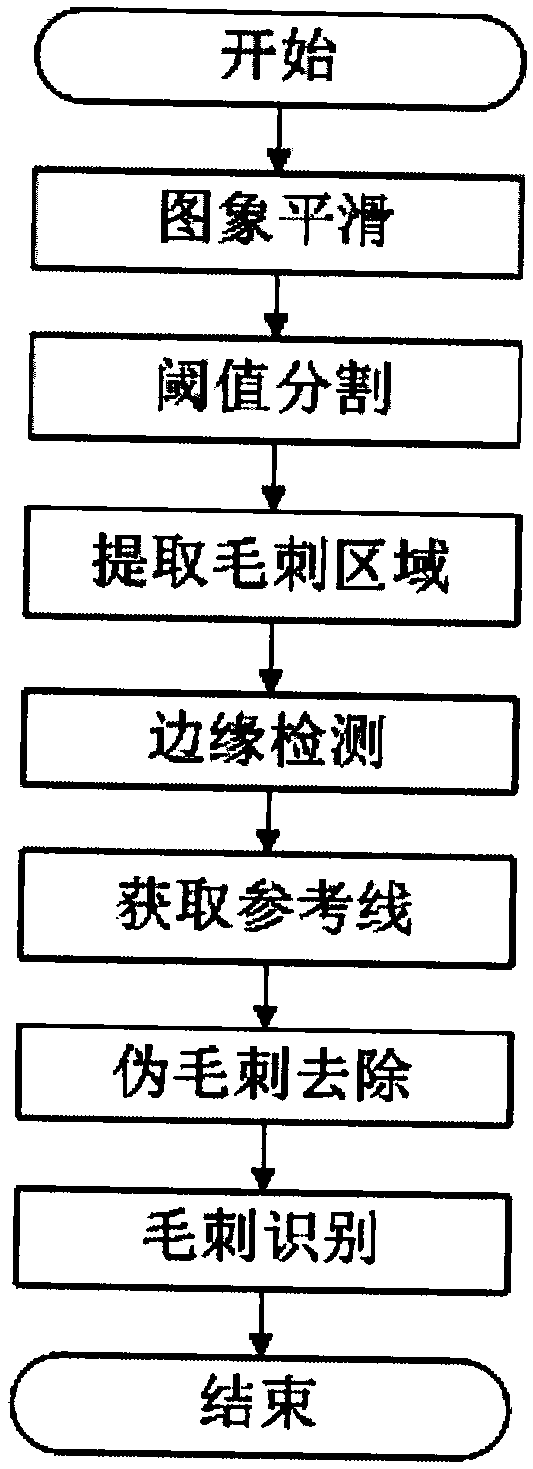

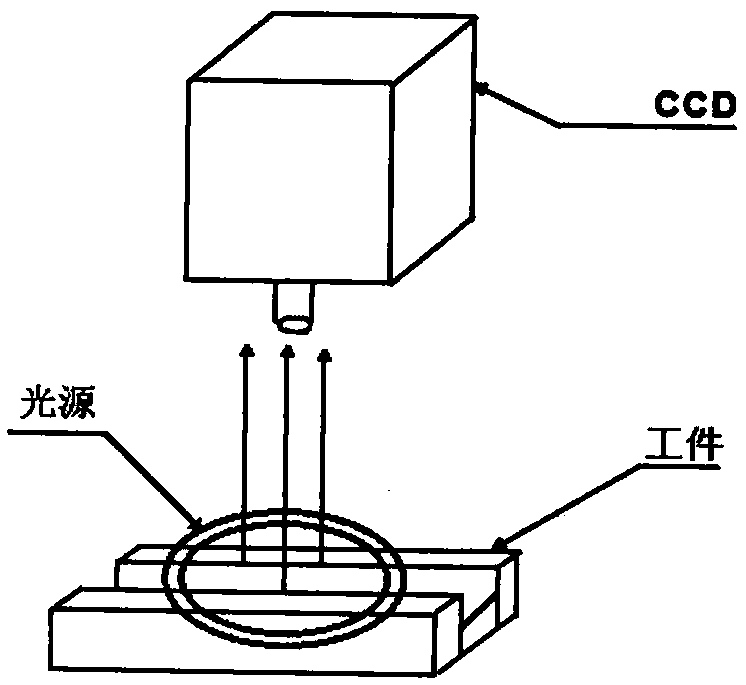

[0057] Such as figure 1 The flow chart of the workpiece burr detection method based on image processing in the present invention is shown, using LED light-emitting semiconductors as the light source to vertically irradiate the surface of the workpiece, using a CCD camera as an image detection device to continuously shoot the edge of the workpiece, and finally using a computer to collect the images taken by the camera. Then filter and segment the collected image, detect the edge of the image, and perform region growing method after the edge is fused. When the grown gray value reaches the set standard, there is no need to expand, indicating that the edge is formed. A closed glitch edge is generated. After that, the false burr is removed by determining the main axis, and finally the burr edge is extracted. Due to the reflective surface of the measured workpiece, how to choose a light source to better highlight the information of the burr, so that the burr is clear at a glance, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com