A kind of aluminum core flexible cable and its manufacturing process

A manufacturing process and flexible cable technology, applied in the direction of cable/conductor manufacturing, conductor/cable insulation, and extensible conductor/cable manufacturing, which can solve the problem that two types of compact conductors and profiled wire structures are not suitable for small bending radii Occasionally use and other problems, to achieve the effect of improving efficiency, reducing costs, and reducing the speed of pay-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The above description is only an overview of the technical solution of the present invention. In order to better understand the technical means of the present invention, it can be implemented according to the contents of the description, and in order to make the above and other purposes, features and advantages of the present invention more obvious and understandable , the specific embodiments of the present invention are enumerated below.

[0042] The invention provides one, for solving the prior art, in order to solve the above problems, the general idea of the present invention is as follows:

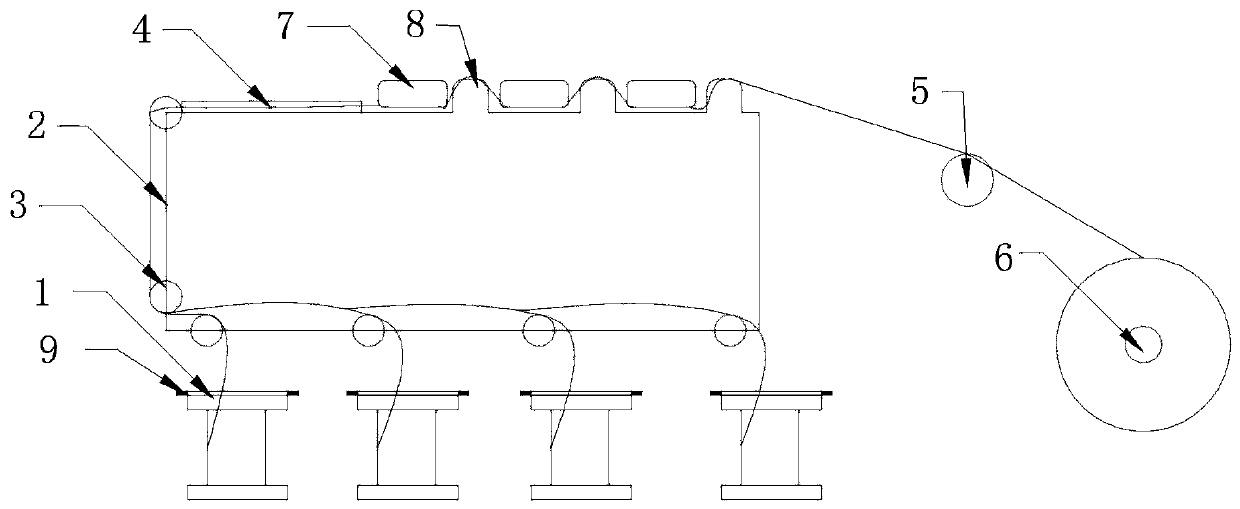

[0043] A manufacturing process of an aluminum core flexible cable, comprising the following steps:

[0044] Step 1, producing aluminum rods;

[0045] Step two, rough drawing;

[0046] Step 3, pull small wire;

[0047] Step 4, doubling wires;

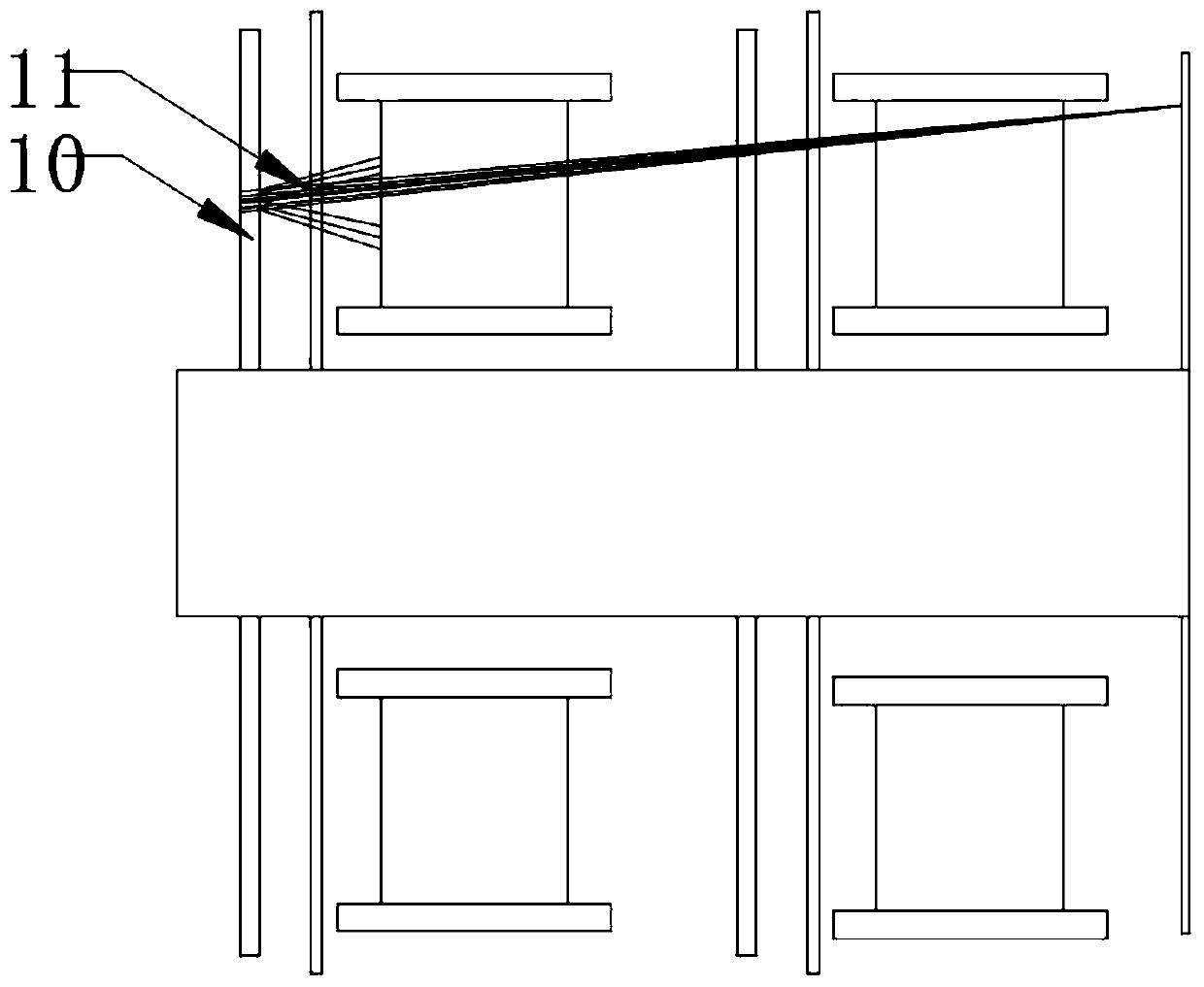

[0048] Step five, beaming;

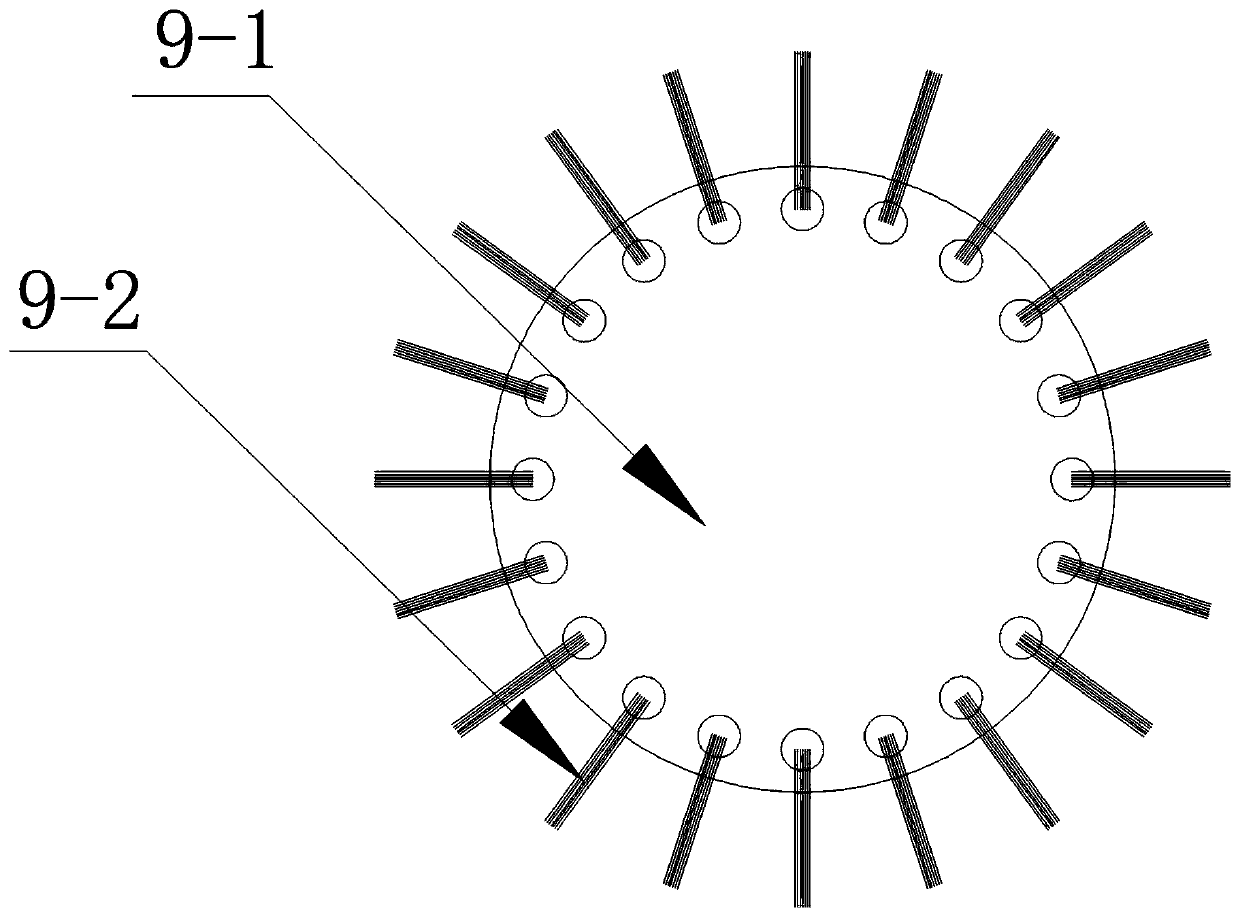

[0049] Step six, re-twisting; layered re-twisting is adopted according to the conductor structure r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com