An intermediate high-conductivity aluminum single wire and its manufacturing method

A manufacturing method and high-conductivity technology, applied in the direction of single-tube conductors, etc., can solve problems such as difficulty in guaranteeing product performance, poor product performance stability, and high energy consumption for annealing, and achieve difficult process control, high product production efficiency, and The effect of fewer drawing dies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

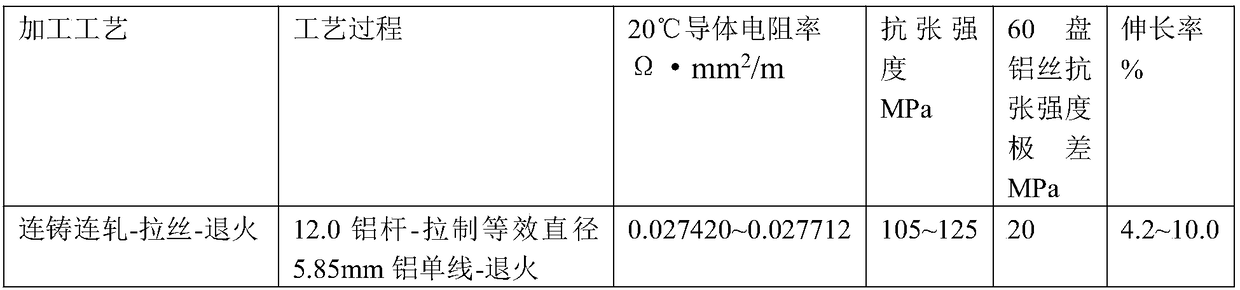

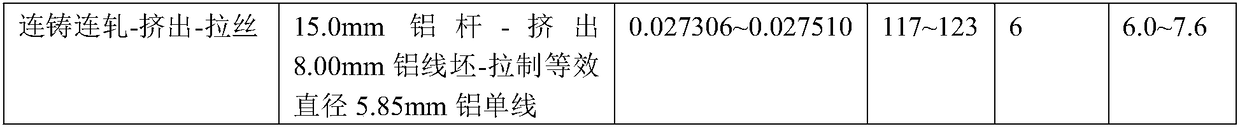

[0024] The production process of the present embodiment is:

[0025] Step 1: Process and produce aluminum rods; produce aluminum rods through smelting, refining, continuous casting and rolling processes of aluminum ingots, and control the performance of aluminum rods to a diameter of 12.0-16.00mm, and a conductor resistivity of 20°C ≤0.02760Ω · mm 2 / m, the tensile strength is 90-120MPa, and the elongation is ≥20.0%. The aluminum ingot is smelted, the alloy composition is configured, and the continuous casting and rolling process is formed into an aluminum rod; the alloy composition configuration controls the mass percentage at: Fe: 0.11 ~0.17%, Si: 0.04~0.06%, Cu<0.001%, Ga≤0.018%, Zn≤0.006%, B: 0.04~0.08%, aluminum alloy liquid holding temperature 730~760℃, casting temperature 680~700℃, The rolling temperature is controlled at 450-500°C.

[0026] Step 2: Extrude the aluminum rod into a soft aluminum wire billet; extrude it with a Kangfang machine, control the extrusion com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com