Fast automatic exposure method and system based on display panel defect detection

A technology for displaying panel defects and automatic exposure, which is applied to control exposure, TV system components, optics, etc., to achieve the effects of fast computing speed, improved effectiveness, and increased robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

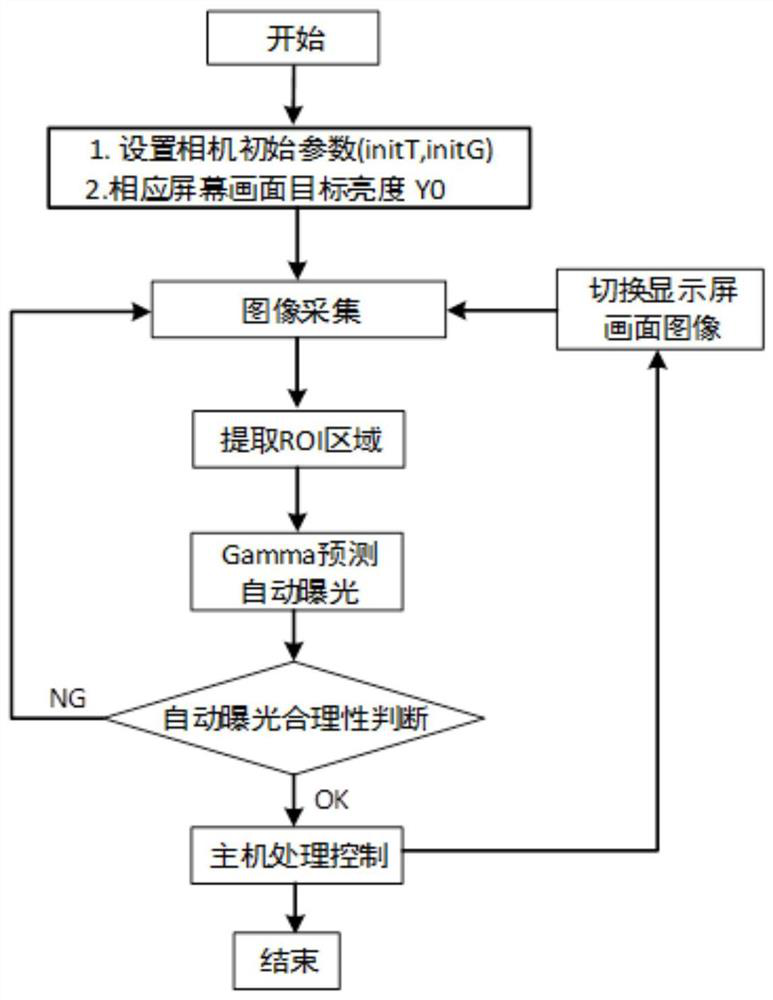

[0068] Such as figure 1 As shown, the process of a fast automatic exposure method based on display panel defect detection in the present invention is as follows:

[0069] Step 1: Set the camera's initial exposure time initT and initial gain initG, and set the target brightness Y0 of each frame to be detected.

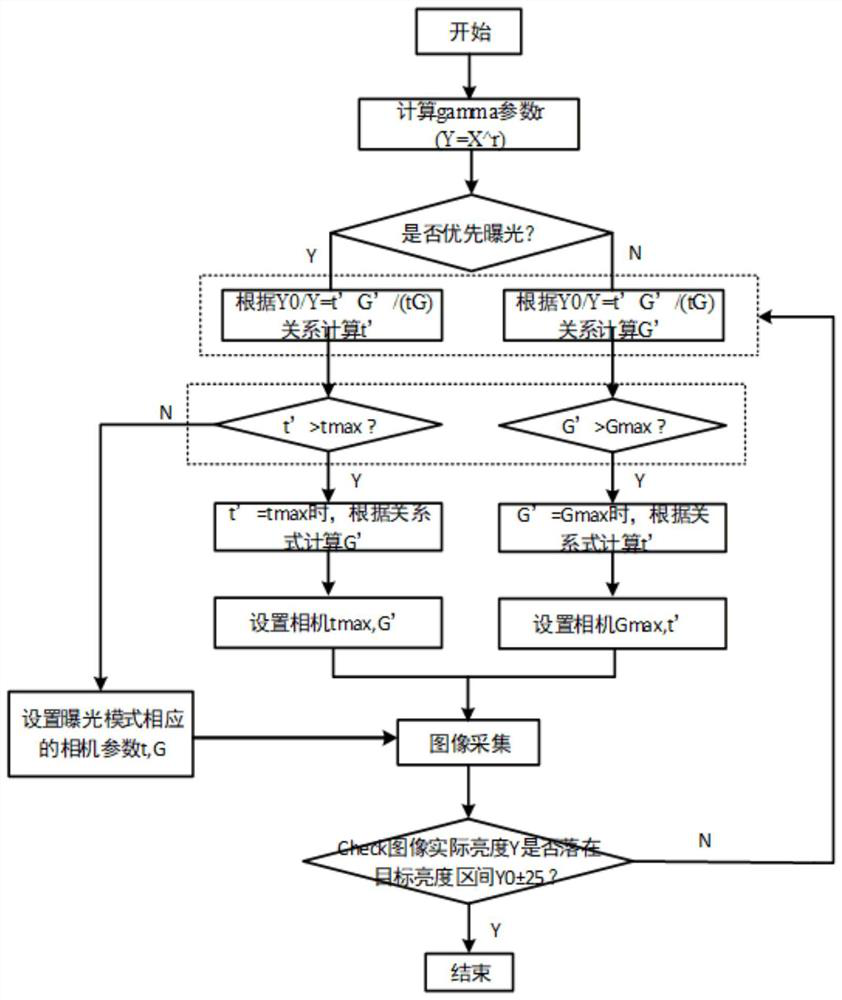

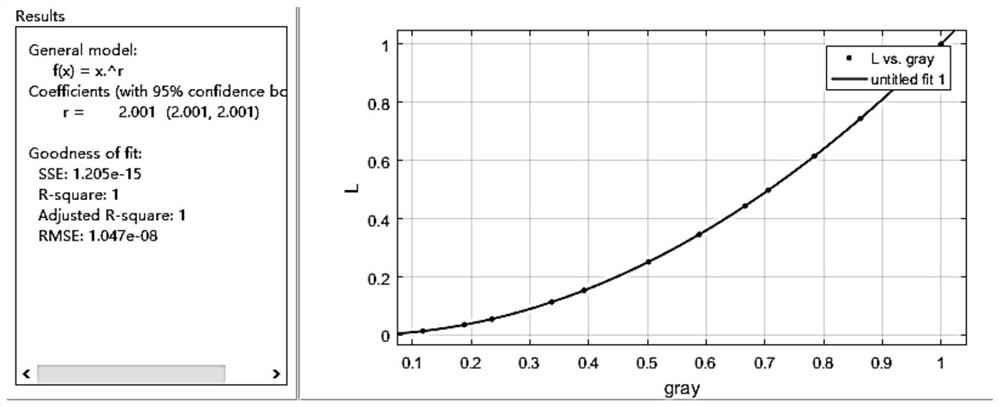

[0070] Step 2: Collect the screen image of the display screen with an actual gray value of 255, and extract the ROI area from the screen image of the display screen. First, according to the collected display screen image (for example, L255 screen) with an actual gray value of 255, image threshold segmentation is performed to obtain the ROI segmentation parameters of the screen (for subsequent image acquisition and ROI extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com