Rotary distribution type honey cooling device

A cooling device and split-flow technology, which is applied in the direction of cooling fluid circulation device, household refrigeration device, lighting and heating equipment, etc., can solve the problem of low cooling efficiency of honey cooling device, achieve ingenious structural design, improve fluidity and cooling efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

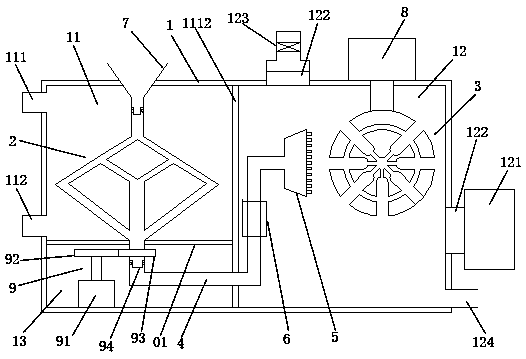

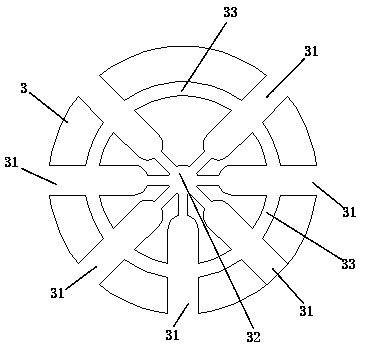

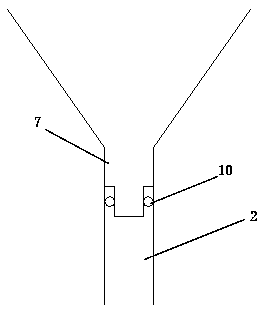

[0020] Such as Figures 1 to 4 As shown, a rotary shunt type honey cooling device includes a cooling box 1, a binary tree cooling pipe 2, a delivery pipe 4, a spray nozzle 5, a rotating ball 3, a driving mechanism 8, and a rotating mechanism 9; the inside of the cooling box 1 A partition plate 1112 is arranged in the middle; the partition plate 1112 divides the cooling box 1 into a left cavity on the left side and a second cooling chamber 12 on the right side; a closing plate 01 is arranged in the cavity on the left side; The closed plate 01 divides the cavity on the left side into a first cooling chamber 11 at the upper end and a rotating driving chamber 13 at the lower end; one side of the first cooling chamber 11 is provided with a water inlet 111 and a water outlet 112 respectively. ; The binary tree cooling pipe 2 is installed in the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com