Method for preparing hypochlorite white mud-based adsorbent for deep removal of complex chromium

An adsorption material and complex state technology, which is applied in the field of preparation of hypochlorite lime-based adsorption materials, can solve problems such as inability to dispose of, and achieve the effects of low cost, simple operation and improved adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

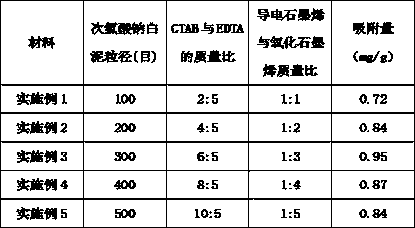

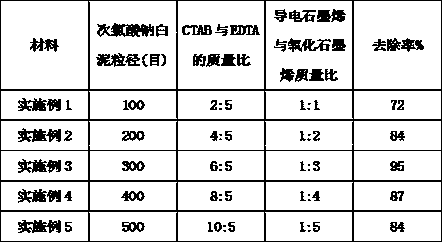

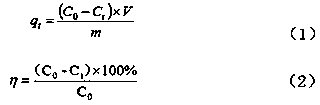

[0024] Example:

[0025] (1) Hypochlorine white mud is dried at 60°C to constant weight, ground and sieved to 100 mesh; 100g of it is added to 200mL of 10% sulfuric acid (H 2 SO 4 ), pickled for 2 hours, filtered to obtain the filtrate;

[0026] (2) Under stirring conditions, add cetyltrimethylammonium bromide (CTAB) 6g to the filtrate in step (1), ultrasonically disperse for 30min; then add ethylenediaminetetraacetic acid (EDTA), according to the mass ratio ( CTAB:EDTA) 2:5;

[0027] (3) Add 0.2g of conductive graphene dispersion (concentration 5mg / ml, conductive graphene sheet diameter 10nm, conductivity 1000S / cm) into 200ml ethanol solution, ultrasonically disperse for 30min; under stirring condition, add to step ( 2) In the obtained product, stir at high speed for 30 minutes, add ball milling beads for ball milling (the particle size of the ball milling beads is 50 μm, the ball milling speed is 100 r / min, and the ball milling time is 30 minutes);

[0028] (4) Under sti...

Example Embodiment

[0031] Example 2:

[0032] (1) Hypochlorite white mud is dried at 60°C to constant weight, ground and sieved to 200 mesh; 100g of it is added to 200mL of 10% sulfuric acid (H 2 SO 4 ), pickled for 2 hours, filtered to obtain the filtrate;

[0033] (2) Under stirring conditions, add cetyltrimethylammonium bromide (CTAB) 7g to the filtrate in step (1), ultrasonically disperse for 30min; then add ethylenediaminetetraacetic acid (EDTA), according to the mass ratio ( CTAB:EDTA) 4:5;

[0034] (3) Add 0.4g of conductive graphene dispersion (concentration 5mg / ml, conductive graphene sheet diameter 10nm, conductivity 1000S / cm) into 200ml ethanol solution, ultrasonically disperse for 30min; under stirring condition, add to step ( 2) In the obtained product, stir at high speed for 30 minutes, then add ball milling beads for ball milling (the particle size of the ball milling beads is 50 μm, the ball milling speed is 200 r / min, and the ball milling time is 60 minutes);

[0035] (4) Un...

Example Embodiment

[0038] Example 3:

[0039] (1) Hypochlorine white mud is dried at 60°C to constant weight, ground and sieved to 300 mesh; 100g of it is added to 200mL of sulfuric acid with a mass concentration of 20% (H 2 SO 4 ), pickled for 4 hours, filtered to obtain the filtrate;

[0040] (2) Under stirring conditions, add cetyltrimethylammonium bromide (CTAB) 8g to the filtrate in step (1), and ultrasonically disperse for 60min; then add ethylenediaminetetraacetic acid (EDTA), according to the mass ratio ( CTAB:EDTA) 6:5;

[0041] (3) Add 0.6 g of conductive graphene dispersion (concentration 5 mg / ml, conductive graphene sheet diameter 1 μm, conductivity 1200 S / cm) into 200 ml ethanol solution, ultrasonically disperse for 60 min; under stirring conditions, add to step ( 2) In the obtained product, stir at high speed for 60 minutes, add ball milling beads for ball milling (ball milling beads particle size 100 μm, ball milling speed 300r / min, ball milling time 90 minutes);

[0042] (4) Un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com