High-performance VOCs (Volatile Organic Compounds) adsorption carbon prepared from wastes and preparation method of adsorption carbon

A waste and high-performance technology, applied in the field of comprehensive utilization of waste resources, can solve problems such as high energy consumption, environmental pollution, and large carbon emissions, and achieve the effect of resource utilization of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

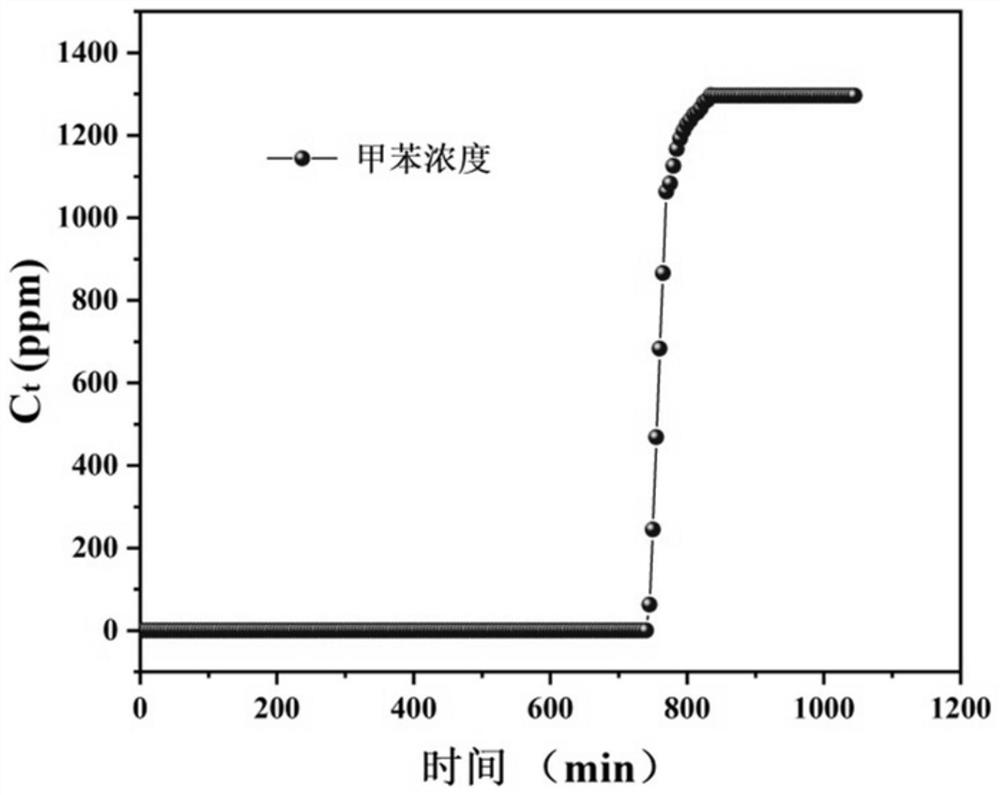

Embodiment 1

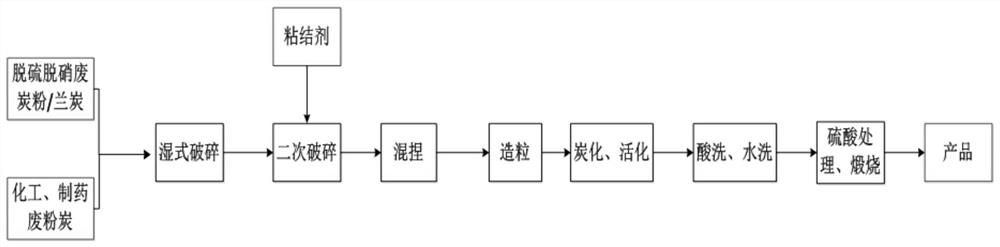

[0036] according to figure 1 The preparation process shown in the preparation of VOCs adsorption carbon, the specific method is:

[0037] 1) Use desulfurization and denitrification waste carbon powder and chemical and pharmaceutical waste powder carbon as raw materials, mix according to the mass ratio of 50%:50%, enter the wet ball mill after mixing, and crush it to a particle size of 400-600 mesh.

[0038] 2) Then add 20% of pre-crushed binder to 200 mesh into the mixed sample to obtain mixed sample 2.

[0039] 3) Put the mixed sample 2 into a ball mill for secondary crushing, and stir to 400-600 mesh. Continue to add the obtained mixed sample into the wheel roller compactor for kneading, add water to the mixed material several times, and stir for 2 hours.

[0040] 4) The obtained kneaded material is exported to a hydraulic granulator for granulation, and the granulated material enters a mesh belt dryer and is dried at 80° C. for 2 hours.

[0041] 5) Then the dried materia...

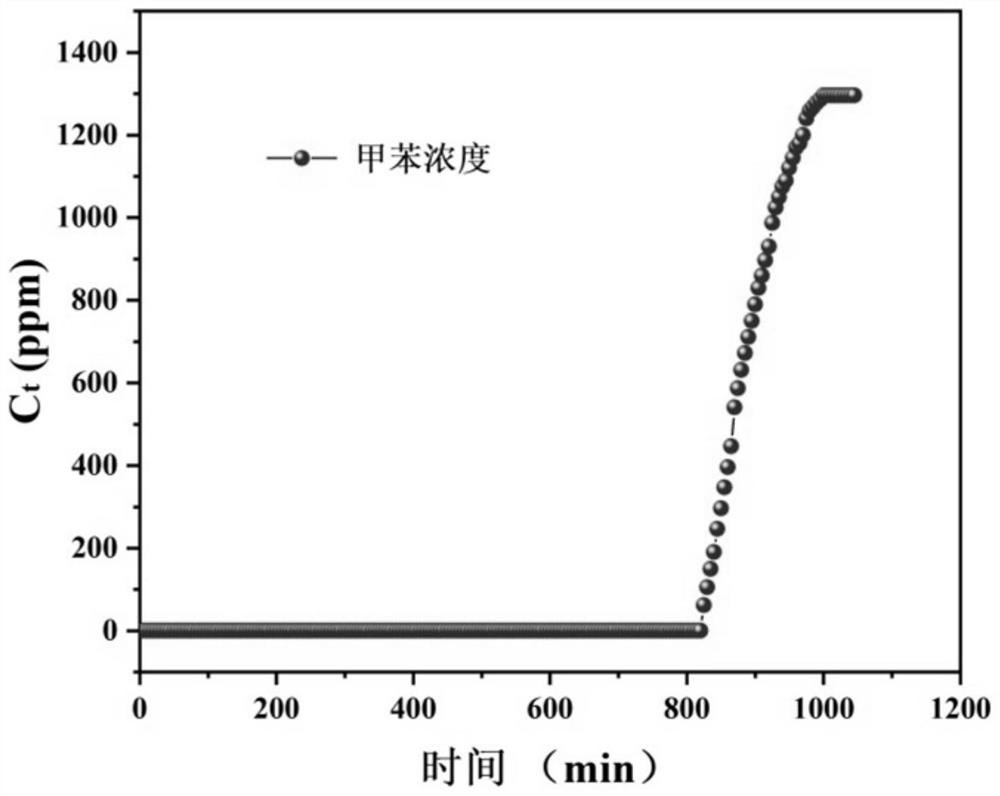

Embodiment 2

[0047] 1) The blue charcoal powder and chemical and pharmaceutical waste powder charcoal are used as raw materials, mixed according to the mass ratio of 40%:60%, and then entered into a wet ball mill for primary crushing to a particle size of 400-600 mesh.

[0048] 2) Then add 20% of pre-crushed binder to 200 mesh into the mixed sample to obtain mixed sample 2.

[0049] 3) Put the mixed sample 2 into a ball mill for secondary crushing, and stir to 400-600 mesh. Continue to add the obtained mixed sample into the wheel roller compactor for kneading, add water to the mixed material several times, and stir for 2 hours.

[0050] 4) The obtained kneaded material is exported to a hydraulic granulator for granulation, and the granulated material enters a mesh belt dryer and is dried at 80° C. for 2 hours.

[0051] 5) Then the dried material enters the internal heating type rotary carbonization furnace for the carbonization process. The carbonization temperature is 700-900° C. and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com