Automatic double-sided welding machine

A technology of double-sided welding and welding mechanism, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to reduce misalignment or detachment, improve welding quality and efficiency, and have good versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

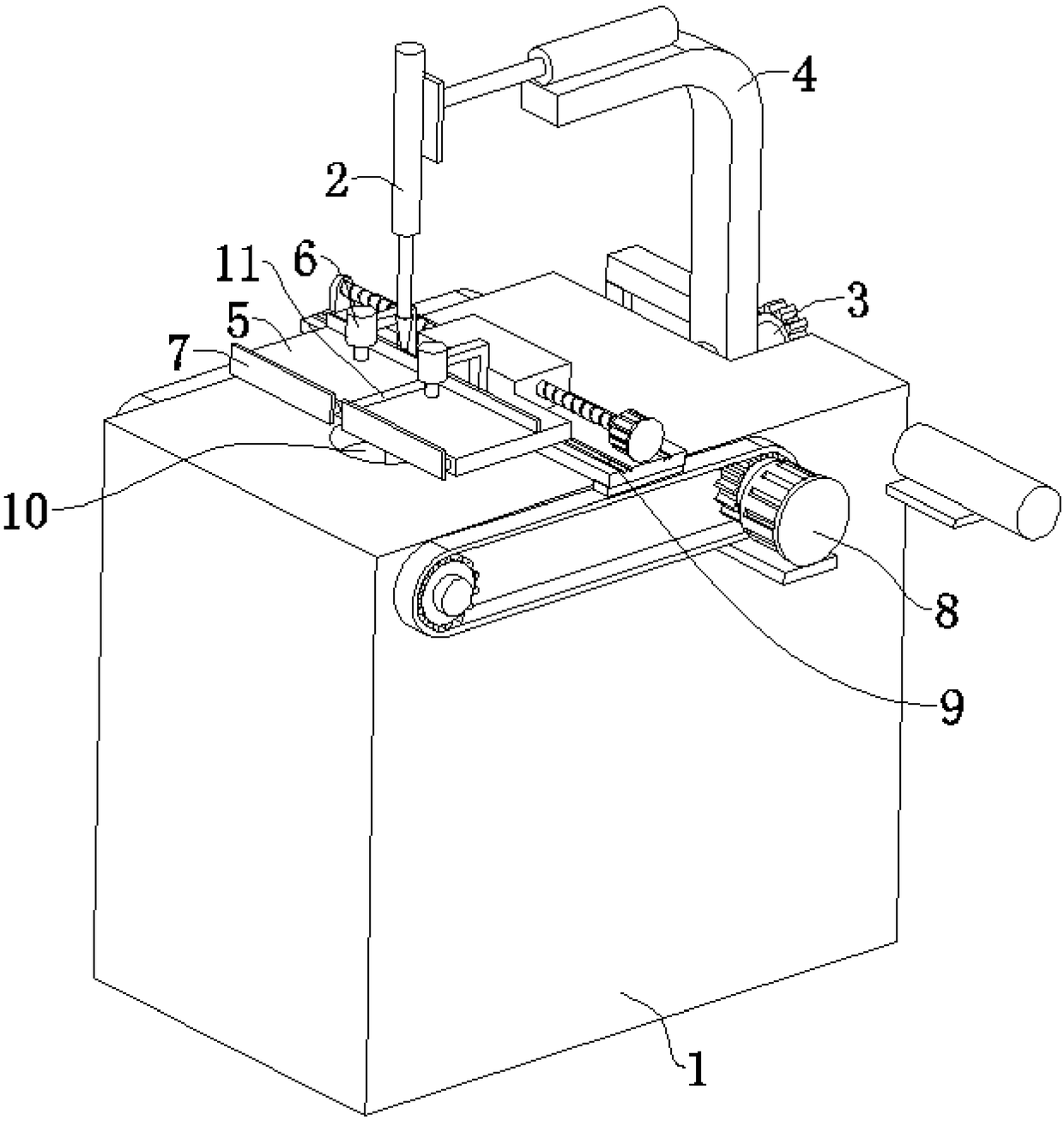

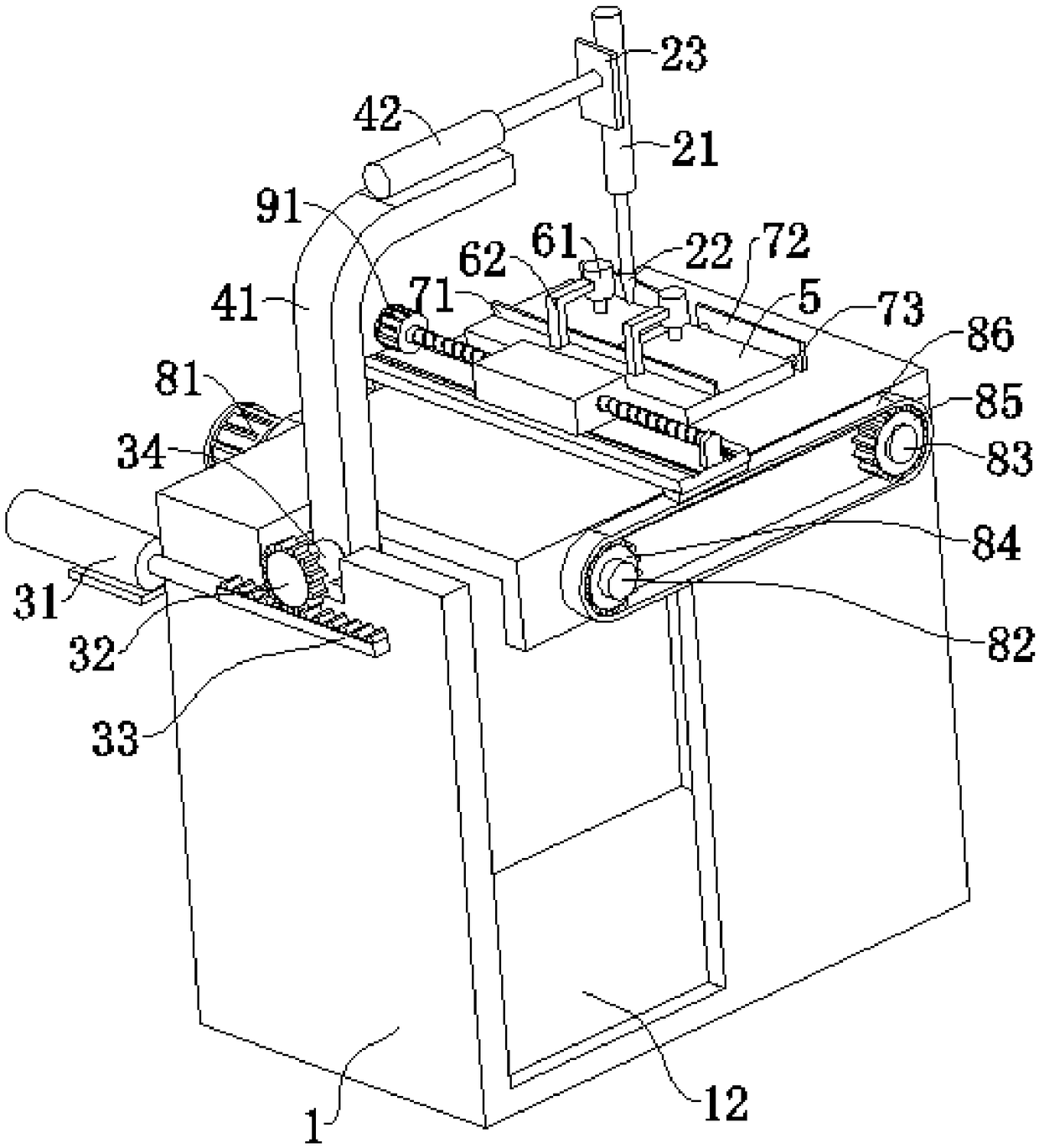

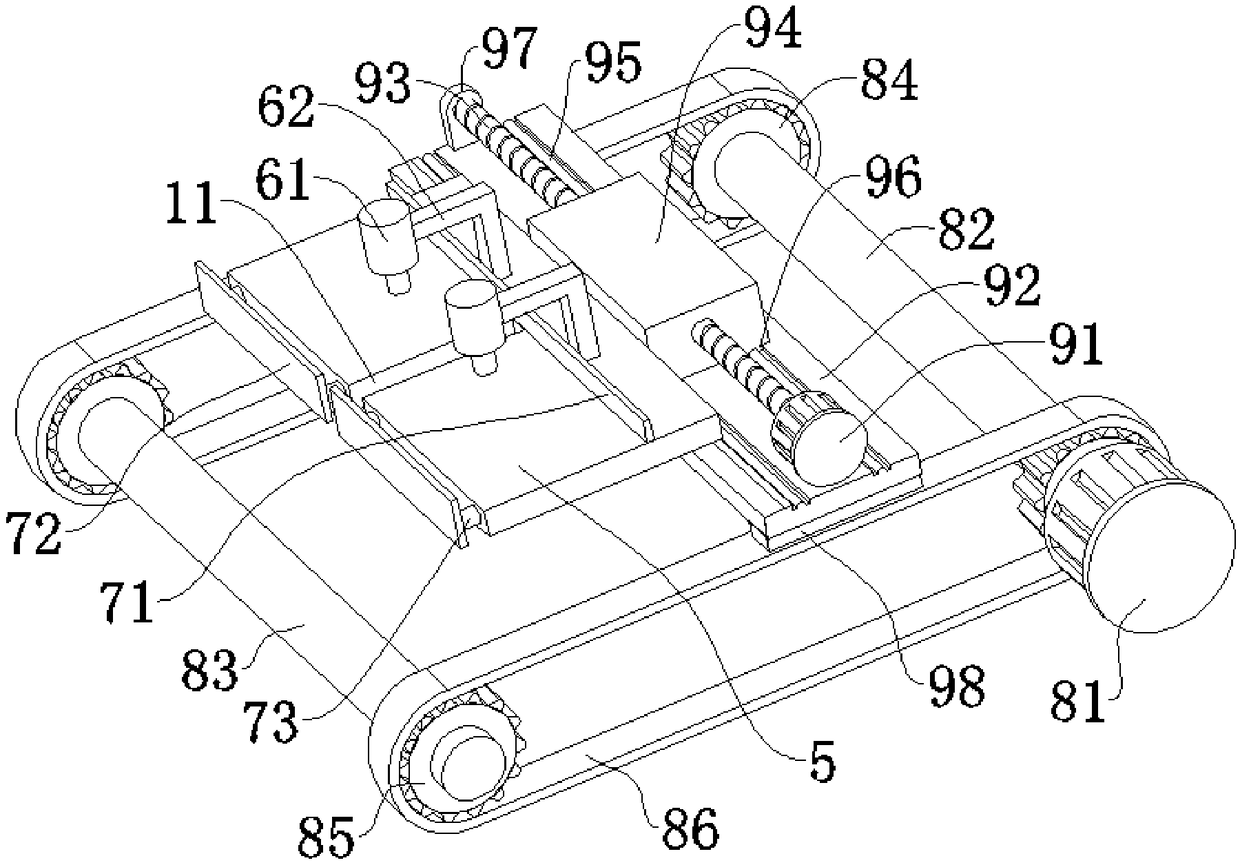

[0036] Embodiment: a kind of automatic double-sided welding machine, as figure 1 , 2 , 3, including the chassis 1, the chassis 1 is provided with a welding mechanism 2, a turning mechanism 3, a fixing mechanism 4, an X-axis transmission module 9, a Y-axis transmission module 8, a placement panel 5, a positioning mechanism 6 and a clamping mechanism. Institution7. The chassis 1 is hollow and has a circular through hole 10 on the top. The placement panel 5 is located above the chassis 1 and is used to place the workpiece to be processed. The placement panel 5 is provided with a slot 11 corresponding to the welding place. The slot 11 Located above the through hole 10 and corresponding to its position. The placement panel 5 is fixed on the X-axis transmission module 9, the X-axis transmission module 9 is fixed on the Y-axis transmission module 8, and the Y-axis transmission module 8 is used to drive the X-axis transmission module 9 and the placement panel 5 along the Y axis. Ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com