Method for control torque of electric vehicle by simulating manual gear fuel vehicle

An electric vehicle, torque control technology, applied in the direction of electric vehicles, control drives, control devices, etc., can solve the problems of clutch burnout, high maintenance costs, easy wear of clutches and multi-speed gearboxes, etc., to improve reliability and durability Sexuality, simplified layout, and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

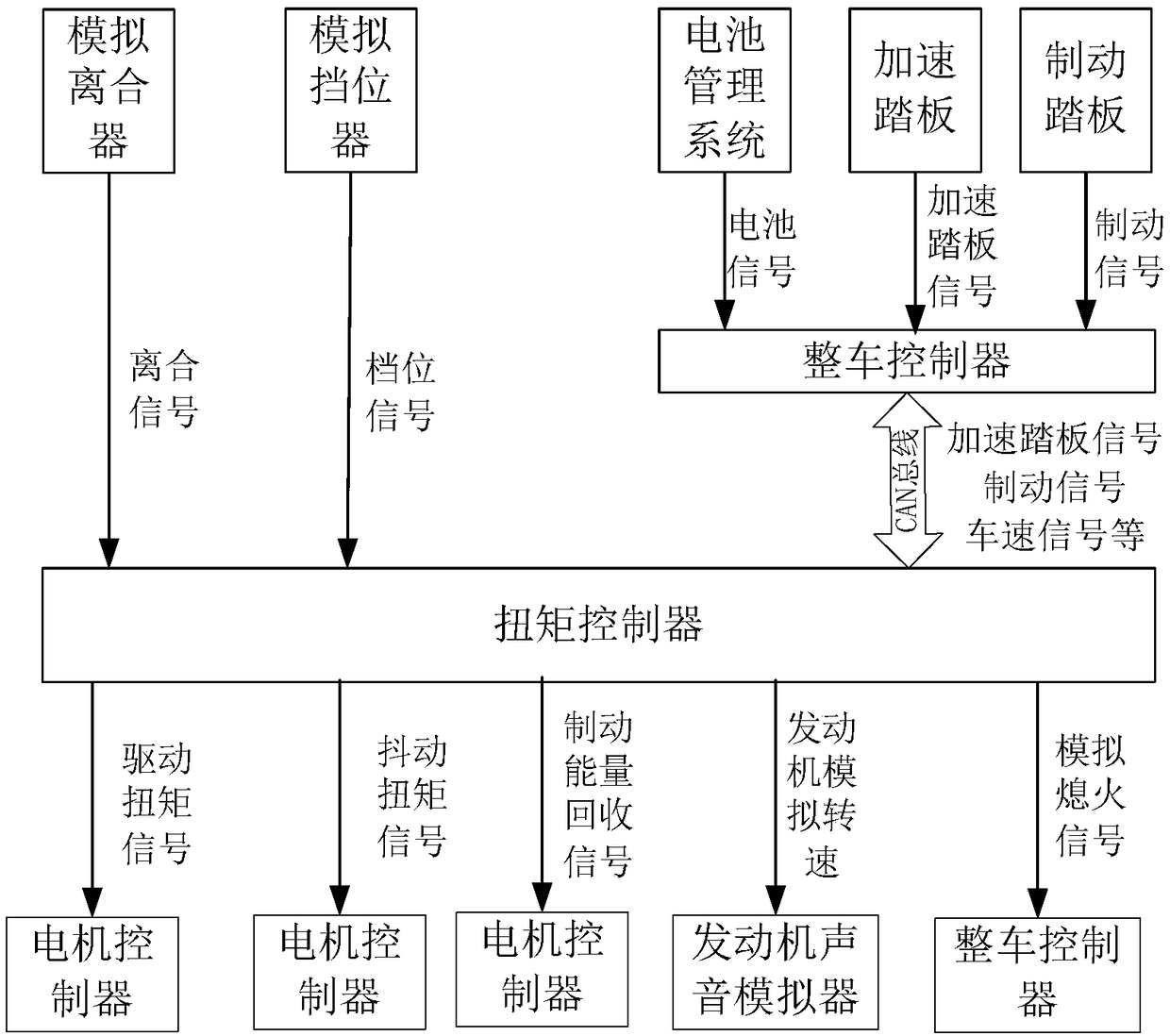

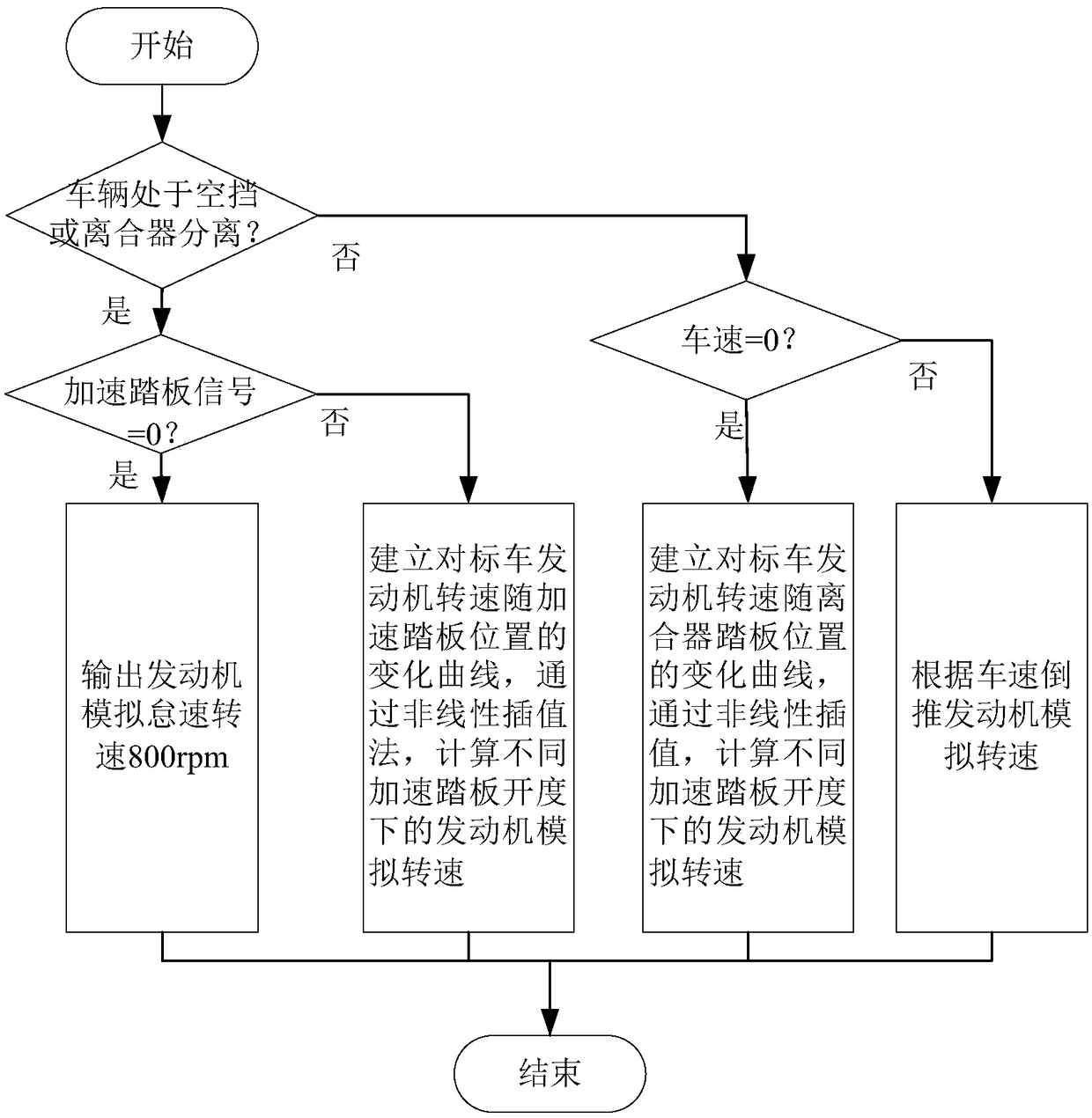

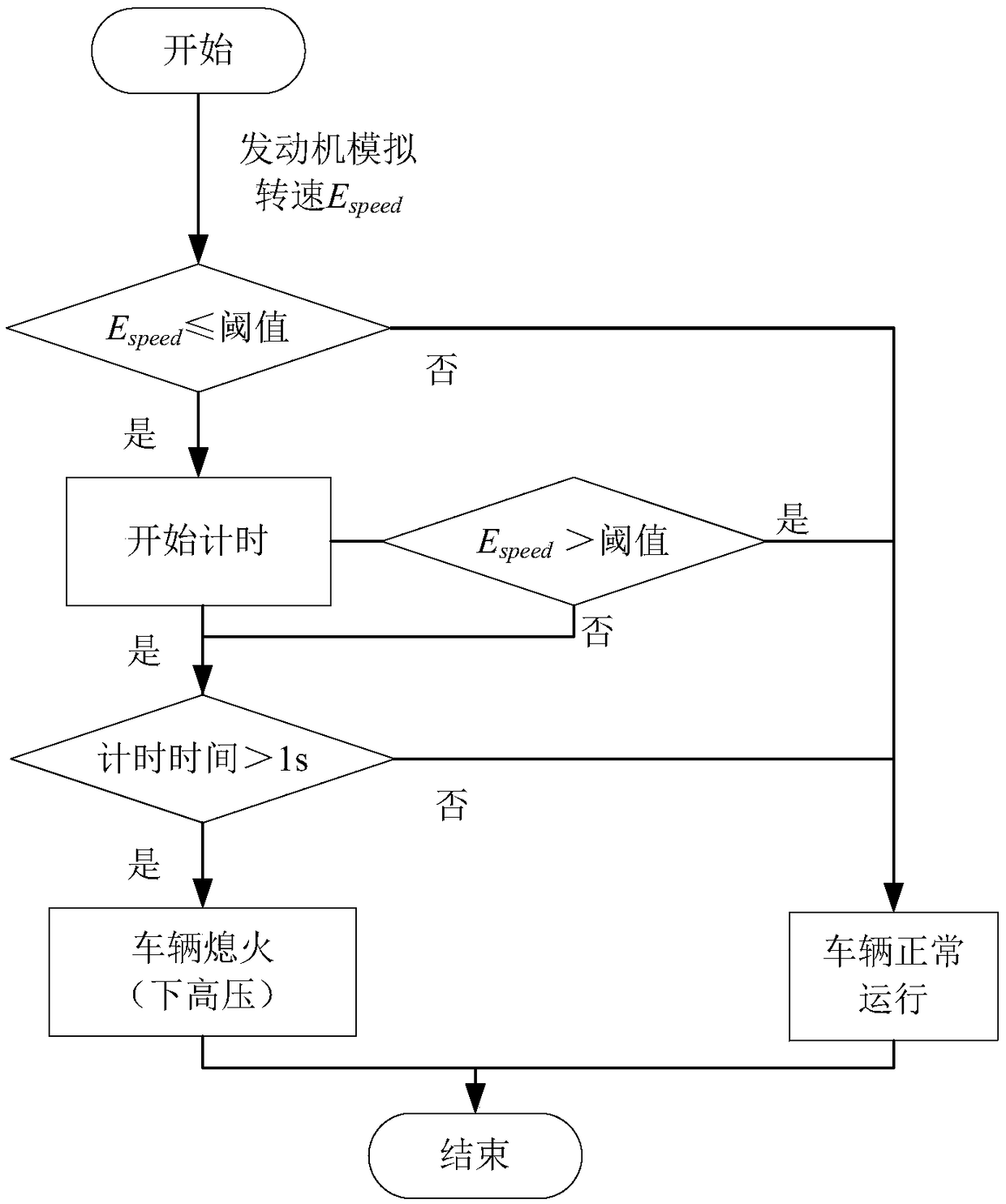

[0024] Such as figure 1 As shown, the torque control method for an electric vehicle simulating a manual transmission fuel vehicle of the present invention is to install a simulated clutch, a simulated gear shifter, a torque controller, etc. on a single-stage deceleration electric vehicle. The simulated clutch is composed of a clutch pedal and a Hall sensor. The gear shifter consists of a manual shift lever and a Hall sensor. The present invention is also provided with an engine sound simulator on the electric vehicle.

[0025] In the embodiment of the present invention, a clutch pedal and a Hall sensor are installed on the left side of the brake pedal of the single-stage deceleration electric vehicle, that is, the position where the clutch pedal is installed on a traditional manual transmission fuel vehicle, and the Hall sensor is installed behind th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com