Heat exchange piece of moisture removal device, moisture removal device and clothes dryer

A technology for heat exchange parts and clothes dryers, which is applied in the fields of moisture removal devices, heat exchange parts, and clothes dryers. Optimized design, increased space, improved heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

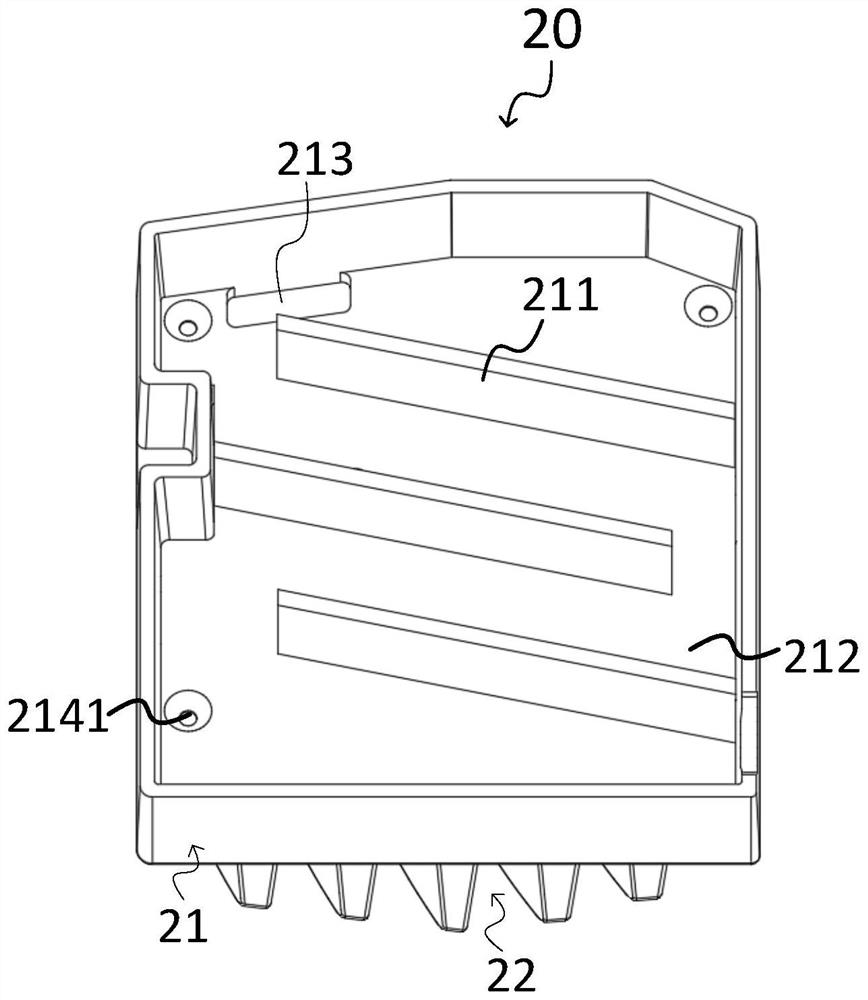

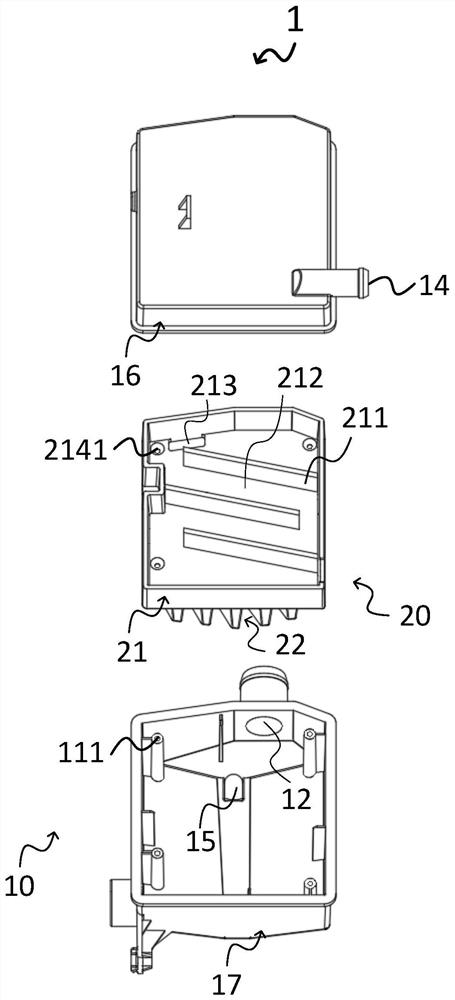

[0045] The present invention provides a heat exchange element for a moisture removal device, such as figure 1 , figure 2 As shown in the figure, it includes a heat exchange element body 20 arranged on the body 1 of the moisture removal device. The heat exchange element body 20 is provided with a cooling part 21 through which a cooling medium is introduced, so as to exchange heat with the moist and hot air contacting the cooling part 21; the cooling part 21 It includes a cavity and a baffle plate 211; the baffle plate 211 is arranged in the cavity to form a cooling channel 212 for the cooling medium to pass through together with the inner contour of the cavity; wherein,

[0046]The baffle 211 is a heat-conducting sheet with thermal conductivity; at least one baffle 211 is obliquely connected to the inner wall of one side of the cavity to increase the contact area with the cooling medium contained in the cooling channel 212 and improve the distance between the baffle and the co...

Embodiment 2

[0064] The invention provides a dehumidification device for a clothes dryer, such as figure 2 As shown, it includes a dehumidification device body 1 arranged in the clothes dryer body, and the dehumidification device body 1 includes:

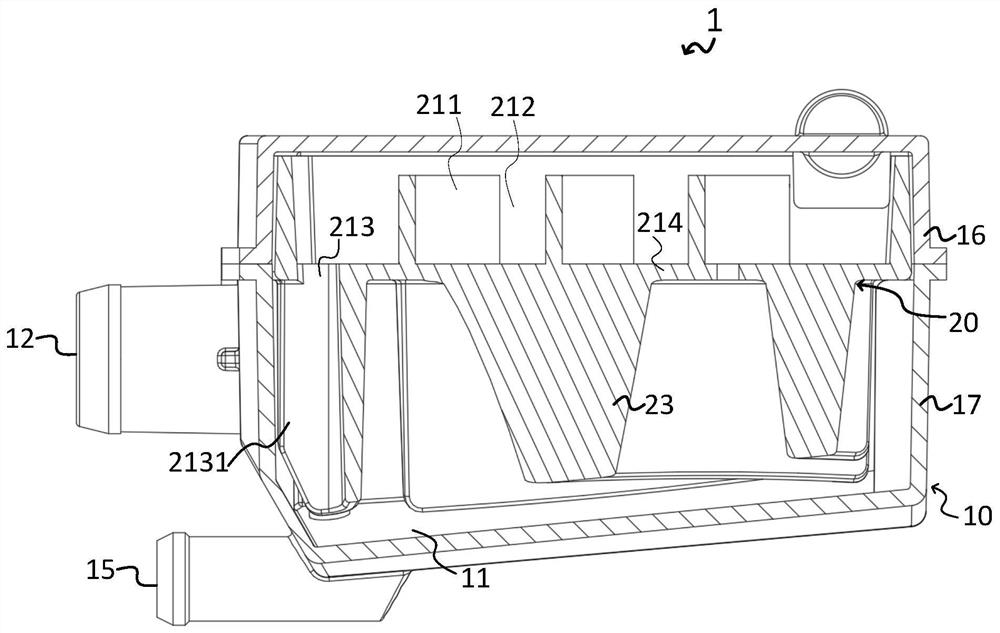

[0065] The housing 10 is provided with a cavity 11 for accommodating the heat exchange element body 20, for accommodating the heat exchange element body 20, and forming a temporary storage space for moist and hot air. After the moist and hot air enters the cavity 11, due to the contour of the cavity 11 The restraint of the damp and hot air reduces the flow speed of the hot and humid air, so that the hot and humid air temporarily gathers in the cavity 11 to contact the body 20 of the heat exchange element in the cavity 11;

[0066] The heat exchange element body 20 described above is used to absorb the heat of the hot and humid air in the cavity 11;

[0067] The humid and hot air generated by the drying drum of the clothes dryer body enters the c...

Embodiment 3

[0083] The present invention provides a clothes dryer, which includes a clothes dryer body for performing drying, and the clothes dryer body includes the above-mentioned moisture removal device body 1 of a moisture removal device for a clothes dryer. The clothes dryer body includes a box body and a clothes dryer; the clothes dryer and the body 1 of the dehumidification device are all arranged in the box body. The humid and hot air in 11 is cooled and dehumidified and the air is discharged out of the box. When the dryer body executes the drying procedure, the hot and humid air in the drying drum passes into the cavity 11 from the air inlet 12, and after the cooling part 21 absorbs heat and cools, the moisture in the hot and humid air is condensed and removed, and then discharged from the air outlet 13. outside the box. The cooling medium after absorbing heat in the cooling channel 212 is discharged into the cavity 11 from the cooling medium outlet 213, and together with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com