Multi-specification bubble cap drug plate automatic pill peeling machine and application thereof

A peeling machine, multi-specification technology, applied in the field of machinery, can solve the problems of inability to realize the counting function of processing medicine plates, inability to realize automatic feeding, low equipment applicability, etc., and achieves high peeling efficiency, simple structure, and convenient transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment is used to illustrate the structure of the multi-standard blister medicine board automatic peeling machine of the present invention.

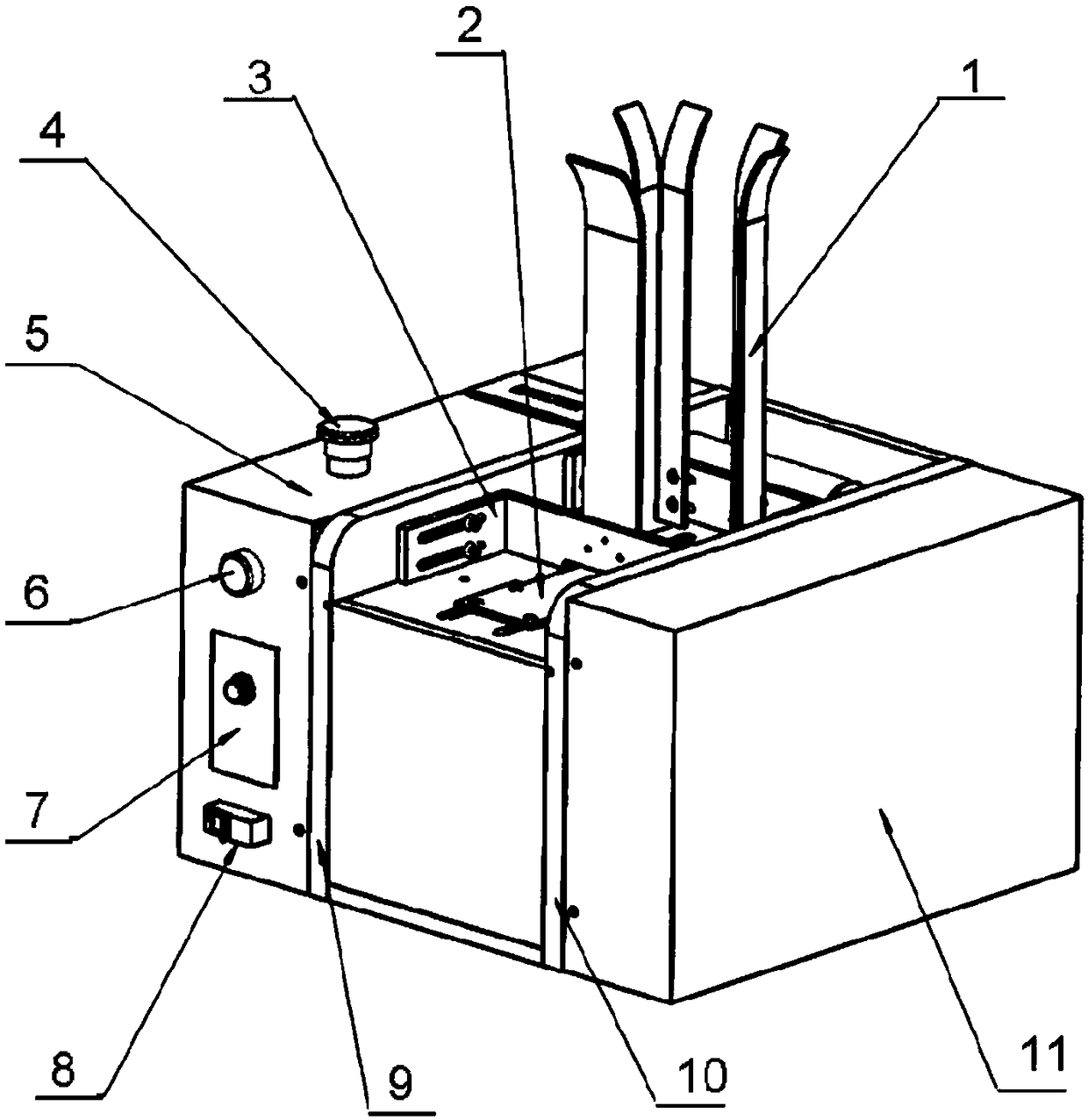

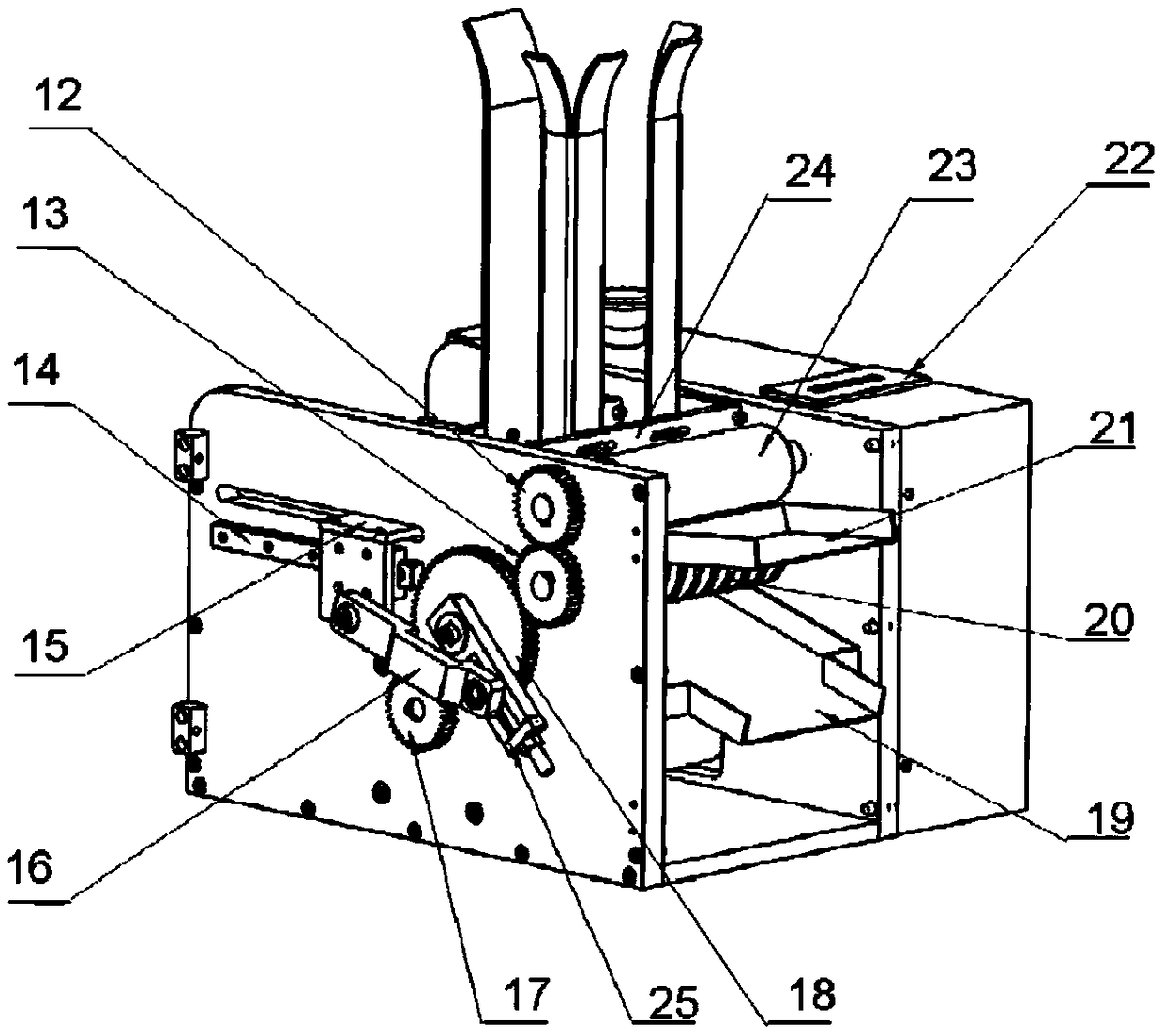

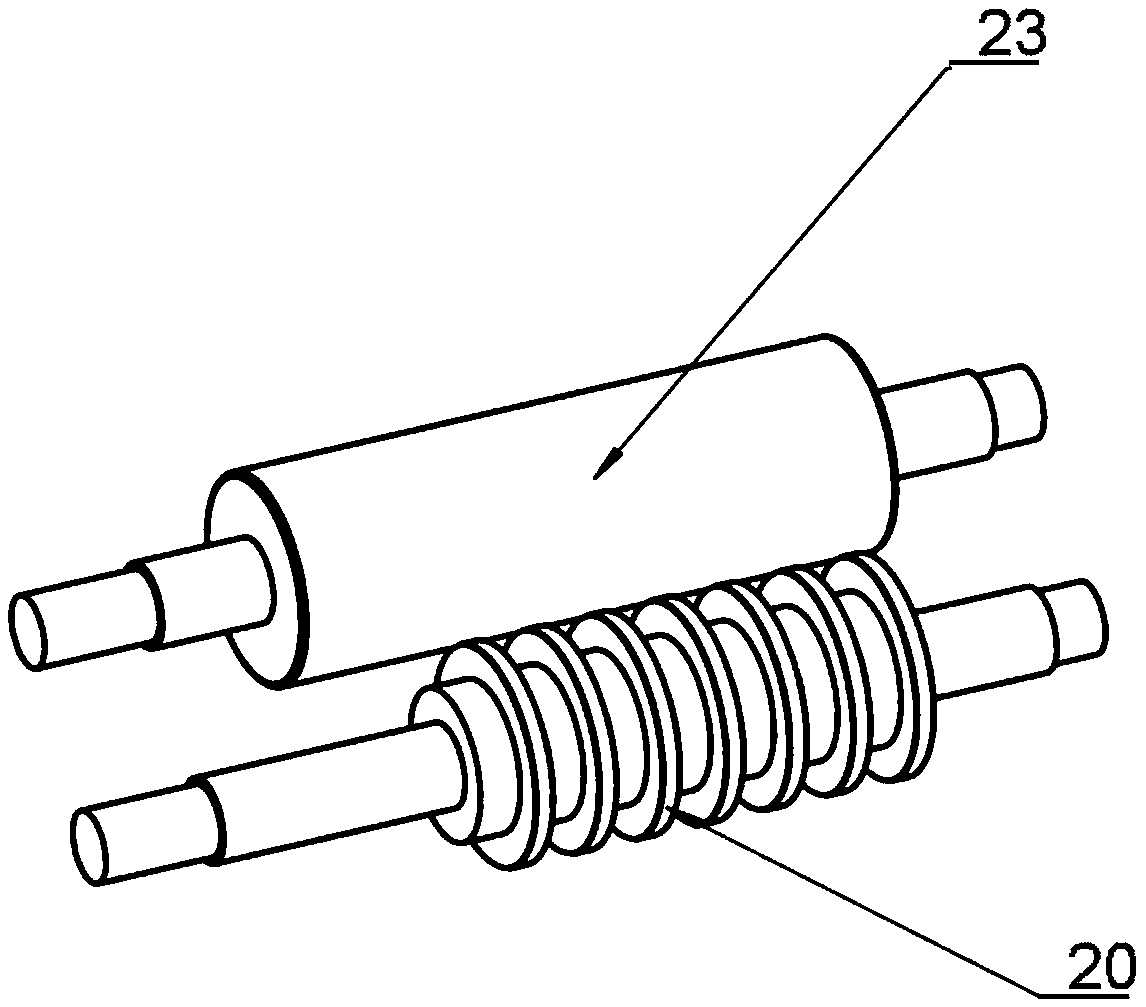

[0040] The overall structure of the present invention is as figure 1 as shown, figure 2 To hide the view of the internal structure of the safety shield on one side, image 3 It is the extruding mechanism for the blister medicine plate.

[0041] Such as figure 1 , 2 As shown, the present invention includes an adjustable silo positioning plate (1), a medicine pushing plate (2), a front adjusting base (3) for adjusting the silo positioning plate according to different specifications, a rear adjusting base (24) and a left safety protection Cover (5) and right safety shield (11), frame left mounting plate (9) and frame right mounting plate (10), drive the transmission gear of upper extrusion roller (23) and lower pressure roller (20) (12) and transmission gear two (13), linear guide rail (14), by connecting the medicine ...

Embodiment 2

[0043] This embodiment is used to illustrate the working principle of the multi-standard blister drug sheet automatic peeling machine of the present invention.

[0044]When the present invention works on the multi-standard blister medicine plate automatic peeling machine, the blister medicine plate is put into the upper silo, and after the equipment power is turned on, the speed-adjustable deceleration motor drives the main transmission gear (17) directly connected with the motor to rotate , the power is transmitted to transmission gear one (12) and transmission gear two (13) by the transition gear (18), which drives the upper squeeze roller (23) to mesh with the lower pressure wheel (20) and rotate. The crank (25) rotates together with the transition gear (18), and at the same time, it drives the connecting rod (16), pushes the medicine plate (2), and the medicine pushing connecting plate (15) drives the medicine pushing plate (2) on the linear guide rail (14) Make a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com