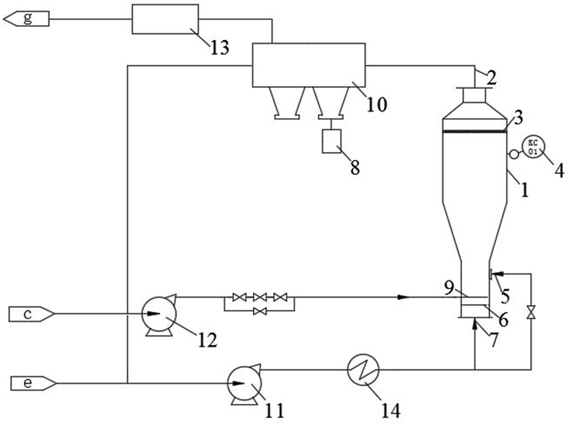

A device system for treating desulfurization wastewater by utilizing waste heat of flue gas from a power plant

A technology for desulfurization wastewater and flue gas waste heat, which is applied in gaseous effluent wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high energy consumption, large equipment footprint and complicated operation. , to achieve the effect of low operating cost, small footprint, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

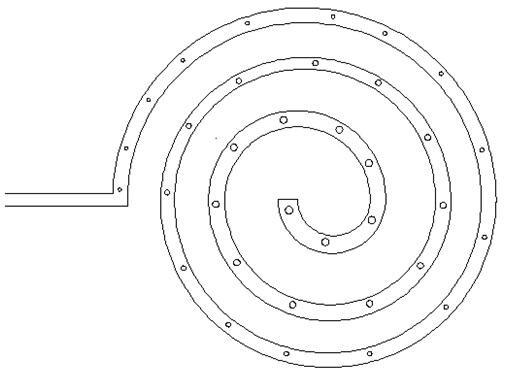

[0034] Embodiment 1: Select the power plant desulfurization wastewater with a moisture content of 95% on a wet basis, feed through the feed device 12 with a feed rate of 1000 kg / h, and the air volume provided by the wind supply device 11 is 2.1 × 10 4 m 3 / h, the inlet air temperature is 300°C; the drying effect of the material is good, the product is collected under the solid recovery tank 8, and the outlet air temperature at the electrostatic precipitator 10 is measured to be about 85°C, and the average moisture content of the product is 3%.

[0035] The specific process is as follows: first close the control valve on the connecting pipeline between the wind supply device 11 and the electrostatic precipitator 10, open the wind supply device 11, and the flow rate of the flue gas sucked into the power plant by the hot flue gas inlet e is 2.1×10 4 m 3 / h (the temperature of the flue gas in the power plant is 300°C), the flow rate to the first air inlet 7 is controlled to be 1...

Embodiment 2

[0036] Embodiment 2: Select the power plant desulfurization wastewater with a moisture content of 95% on a wet basis, feed through the feed device 12 with a feed rate of 500 kg / h, and the air volume provided by the wind supply device 11 is 1.6 × 10 4 m 3 / h, the air inlet temperature of the air supply device is 300°C; the drying effect of the material is good, the product is collected under the electrostatic precipitator, and the outlet air temperature at 10 of the electrostatic precipitator is measured to be about 150°C, and the average moisture content of the product on a wet basis is 2%.

[0037] The specific process is as follows: first close the control valve on the connecting pipeline between the wind supply device 11 and the electrostatic precipitator 10, open the wind supply device 11, and the flow rate of the flue gas sucked into the power plant by the hot flue gas inlet e is 1.6×10 4 m 3 / h (the temperature of the flue gas in the power plant is 300°C), the flow ra...

Embodiment 3

[0038] Embodiment 3: Select the power plant desulfurization wastewater with a moisture content of 95% on a wet basis, feed through the feed device 12 with a feed rate of 40kg / h, and the air volume provided by the wind supply device 11 is 2.0 × 10 3 m 3 / h, the air inlet temperature of the air supply device 11 is 300°C; the drying effect of the material is good, the product is collected under the electrostatic precipitator, and the outlet air temperature of the electrostatic precipitator 10 is measured to be about 200°C, and the average moisture content of the product on a wet basis is 2%. )

[0039] The specific process is as follows: first close the control valve on the connecting pipeline between the wind supply device 11 and the electrostatic precipitator 10, open the wind supply device 11, and the flow rate of the flue gas sucked into the power plant by the hot flue gas inlet e is 2.0×10 3 m 3 / h (the temperature of the flue gas in the power plant is 300°C), the flow ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com