Two-stage first kind absorption heat pump

An absorption heat pump and absorber technology, applied in the field of low-temperature waste heat utilization, can solve the problems of high cost, complex structure, and restrictions on the first type of absorption heat pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

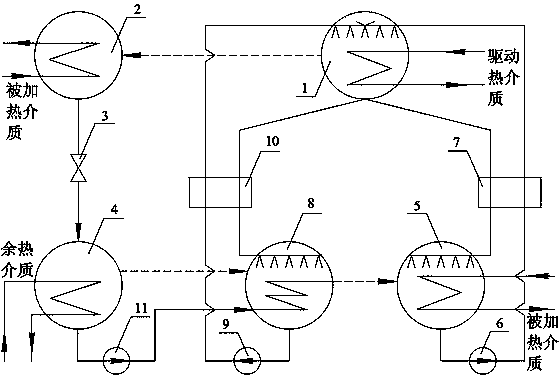

[0007] A two-stage first-class absorption heat pump is realized in this way

[0008] Structurally, it consists of generator 1, first absorber 5, second absorber 8, evaporator 4, condenser 2, throttle valve 3, first solution pump 6, second solution pump 9, first solution heat The exchanger 7, the second solution heat exchanger 10 and the refrigerant liquid pump 11 are composed, and the first absorber 5 has a dilute solution pipeline communicating with the generator 1 through the first solution pump 6 and the first solution heat exchanger 7, The second absorber 8 has a dilute solution pipeline that communicates with the generator 1 through the second solution pump 9 and the second solution heat exchanger 10, and the generator 1 has a concentrated solution pipeline that passes through the first solution heat exchanger 7 and the second solution heat exchanger 7 respectively. The solution heat exchanger 10 enters the first absorber 5 and the second absorber 8, the generator 1 also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com