A kind of technology of removing hydrazine hydrochloride in tert-butylhydrazine hydrochloride

A technology of tert-butyl hydrazine and hydrochloride, applied in the field of pesticide intermediates and pesticides, can solve the problems of high solubility of tert-butyl hydrazine hydrochloride, low yield, and insignificant changes in solubility with temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

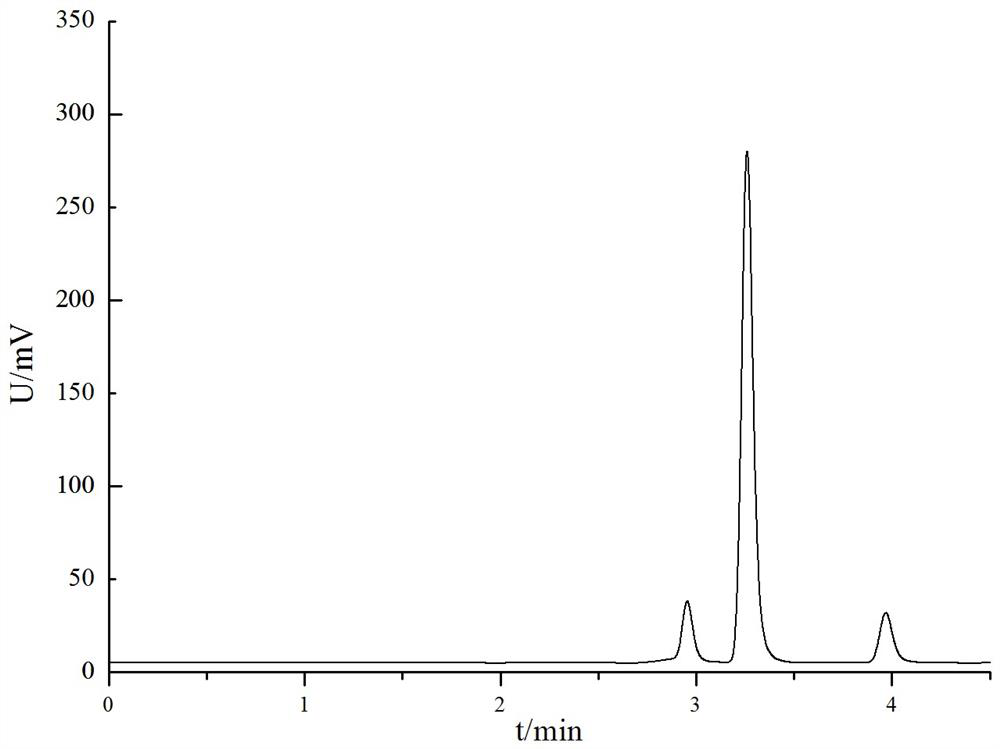

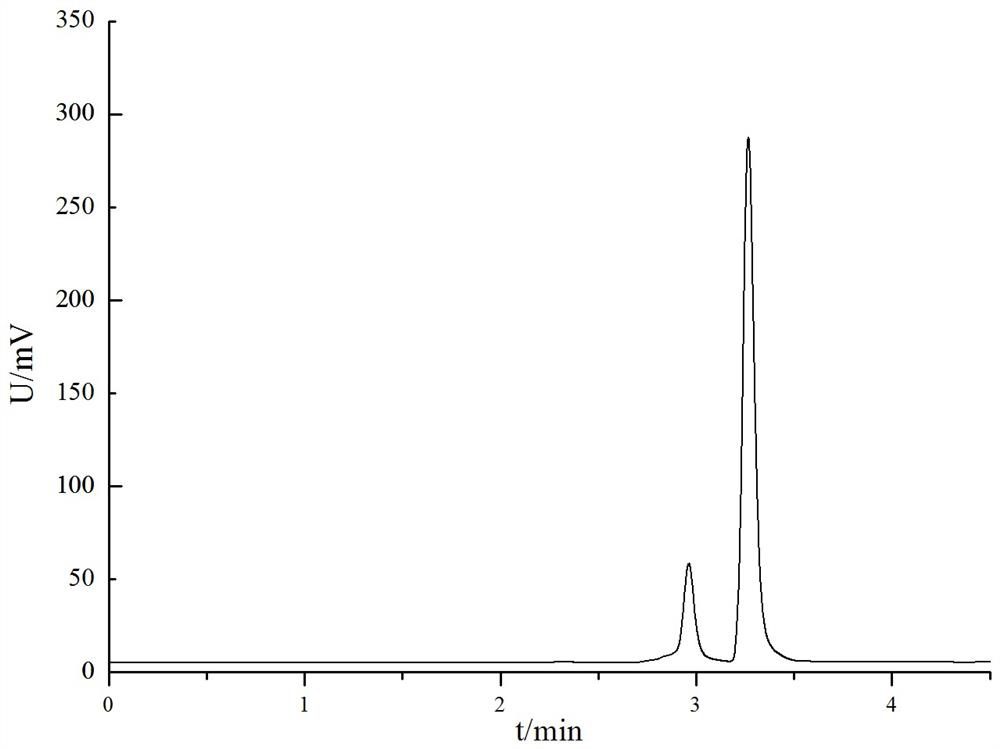

[0020] In a 100mL flask equipped with a stirring device and a reflux device, add 20mL of absolute ethanol, 6.00g of 89.36% (w / w) tert-butylhydrazine hydrochloride, stir in a water bath at 60°C to dissolve, cool to room temperature, and add bicarbonate Ammonium 0.90g, reacted at room temperature for 2 hours, filtered after the reaction, and washed the filter cake with a small amount of ethanol. The filtrate was recovered and applied once, and the operation method was the same as above. The filter cake was dried to obtain a total of 10.48 g of white powder. As determined by high performance liquid chromatography, the content of tert-butylhydrazine hydrochloride was 91.86%, and the yield was 89.78%.

Embodiment 2

[0022] In a 100mL flask equipped with a stirring device and a reflux device, add 20mL of 98% (v / v) ethanol, 8.00g of 89.36% (w / w) tert-butylhydrazine hydrochloride, stir in a water bath at 70°C to dissolve, and cool to At room temperature, add 1.60 g of ammonium bicarbonate, react at room temperature for 1 hour, filter after the reaction, and wash the filter cake with a small amount of ethanol. The filtrate was recovered and applied mechanically twice, and the operation method was the same as above. The filter cake was dried to obtain a total of 19.80 g of white powder. As determined by high performance liquid chromatography, the content of tert-butylhydrazine hydrochloride was 90.72%, and the yield was 92.32%.

Embodiment 3

[0024] In a 100mL flask equipped with a stirring device and a reflux device, add 20mL of 95% (v / v) ethanol, 10.00g of 89.36% (w / w) tert-butylhydrazine hydrochloride, stir in a water bath at 80°C to dissolve, and cool to At room temperature, add 2.00 g of ammonium bicarbonate, react at room temperature for 1 hour, filter after the reaction, and wash the filter cake with a small amount of ethanol. The filtrate was recovered and applied mechanically 3 times, and the operation method was the same as above. The filter cake was dried to obtain a total of 33.56 g of white powder. As determined by high performance liquid chromatography, the content of tert-butylhydrazine hydrochloride was 89.14%, and the yield was 93.89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com