Waterproof construction process of comprehensive pipe rack

A construction process and technology of integrated pipe gallery, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of easy water leakage, weak sealing, complicated operation, etc. The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

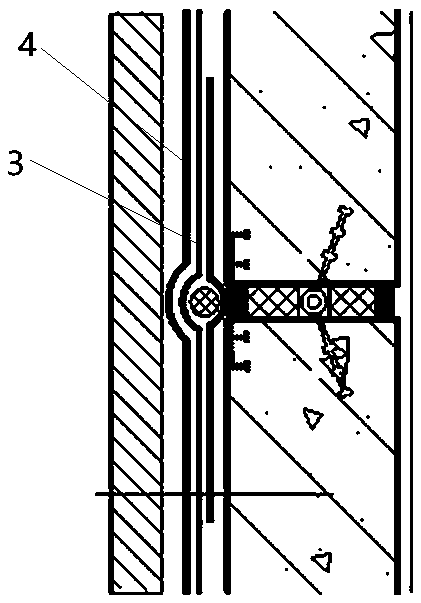

[0035] In the early stage of waterproof construction, carefully review the construction drawings and familiarize yourself with the drawings, and understand the waterproof detail construction methods and technical requirements during construction.

[0036] According to the actual situation of the project, a feasible special construction plan is prepared, which can only be implemented after approval. Before construction, do a good job in the written technical disclosure work of the operators. Carefully review the drawings and corresponding specifications, master the performance and technical indicators of waterproof materials and construction techniques, especially the treatment of special parts such as waterproof ends and yin and yang corners, so that the key points during construction are prominent and well known.

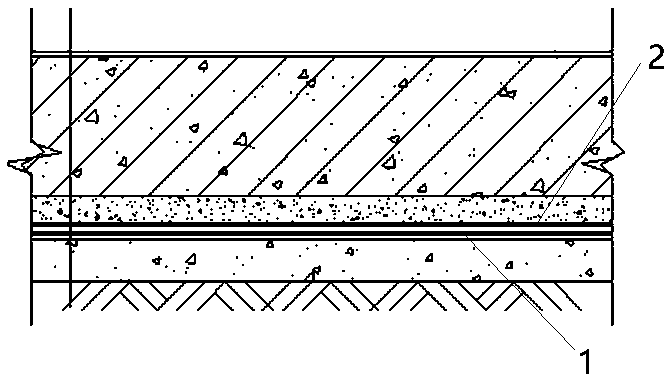

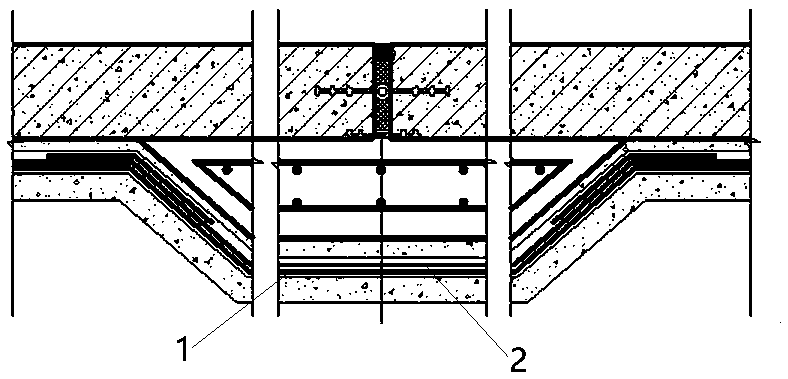

[0037] 1. Floor waterproofing construction process

[0038] Concrete underlayment of the bottom slab → surface cleaning of the base layer of the bottom slab → det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com