Coal mining cutting tooth processed through microbeam plasma arc surface cladding and processing method thereof

A plasma arc and cladding technology, used in the field of coal mining picks, can solve the problems of unsatisfactory picks, achieve high hardness, improve life, and solve the effects of short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

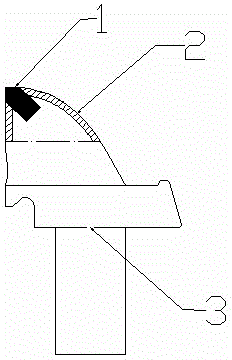

[0028] For the finished pick-shaped coal mining pick, the front part of the cone of the pick pick is ground 2 mm within 20 to 30 mm, and then along the conical surface, a layer of wear-resistant alloy is surfacing by using the micro-beam plasma arc cladding process; when surfacing, use high temperature Glue (high temperature resistance above 1000°C) covers the exposed part of the hard alloy head.

[0029] The mass percentage content of the main elements of the wear-resistant alloy is C 1.47%, Fe 2.0%, Si 2.8%, B2.4%, Cr 14%, Ni 58.4%, W16.53%, Co2.4%.

[0030] Microbeam plasma arc cladding process: input power 220V, rated power 4KAV, output current 65A, ion gas flow rate 0.2L / min, powder feeding gas flow rate 0.6L / min, protective gas flow rate 5 L / min, powder feeding volume 30g / min min, the thickness of one surfacing welding is 2mm, the width of one surfacing welding is 4mm, the powder particle size is 100-300 mesh, and the working distance is 10mm.

[0031] Ion gas, powder f...

Embodiment 2

[0034] For the finished pick-shaped coal mining pick, the front part of the cone is ground 2 mm within the range of 20-30 mm, and then along the conical surface, a layer of wear-resistant alloy is surfacing by using the micro-beam plasma arc cladding process; Tin foil covers the exposed part of the carbide head.

[0035] The mass percentage content of the main elements of the wear-resistant alloy is C 1.95%, Fe 4.0%, Si 4.02%, B3.6%, Cr 20%, Ni 47.5%, W16.53%, Co2.4%.

[0036] Microbeam plasma arc cladding process: input power 220V, rated power 4KAV, output current 70A, ion gas flow 0.3L / min, powder feeding gas flow 0.6L / min, protective gas flow 5L / min, powder feeding 40g / min , a surfacing thickness of 2mm, a surfacing width of 4mm, powder particle size of 100-300 mesh, working distance of 10mm.

[0037] Ion gas, powder feeding gas and shielding gas are all 99.99% industrial argon.

[0038] The surface hardness of the wear-resistant alloy coating is HRC61.5.

Embodiment 3

[0040] For the finished knife-type coal mining picks, firstly grind 1-3mm within the range of 20-30mm in the front part, and then use the micro-beam plasma arc cladding process to surfacing a layer of wear-resistant alloy along the conical surface; Cement covers the exposed portion of the carbide head.

[0041] The mass percentage content of the main elements of the wear-resistant alloy is C 1.47%, Si 2.8%, B2.0%, Cr 12%, Ni 62.8%, W16.53%, Co2.4%.

[0042] Microbeam plasma arc cladding process: input power 220V, rated power 4KAV, output current 70A, ion gas flow 0.3L / min, powder feeding gas flow 0.6L / min, protective gas flow 5L / min, powder feeding 40g / min , a surfacing thickness of 2mm, a surfacing width of 4mm, powder particle size of 100-300 mesh, working distance of 10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com