Hanger rod device for hearth charging of lime double-hearth shaft kiln

A double-chamber vertical kiln and hanger technology, which is applied in the field of metallurgical kiln technology and a kind of feeding equipment, can solve the problems of difficult sealing, high working oil pressure of hydraulic cylinders, large multi-dimensional swing errors, etc., to solve environmental pollution , prolong the service life and reduce the effect of working oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

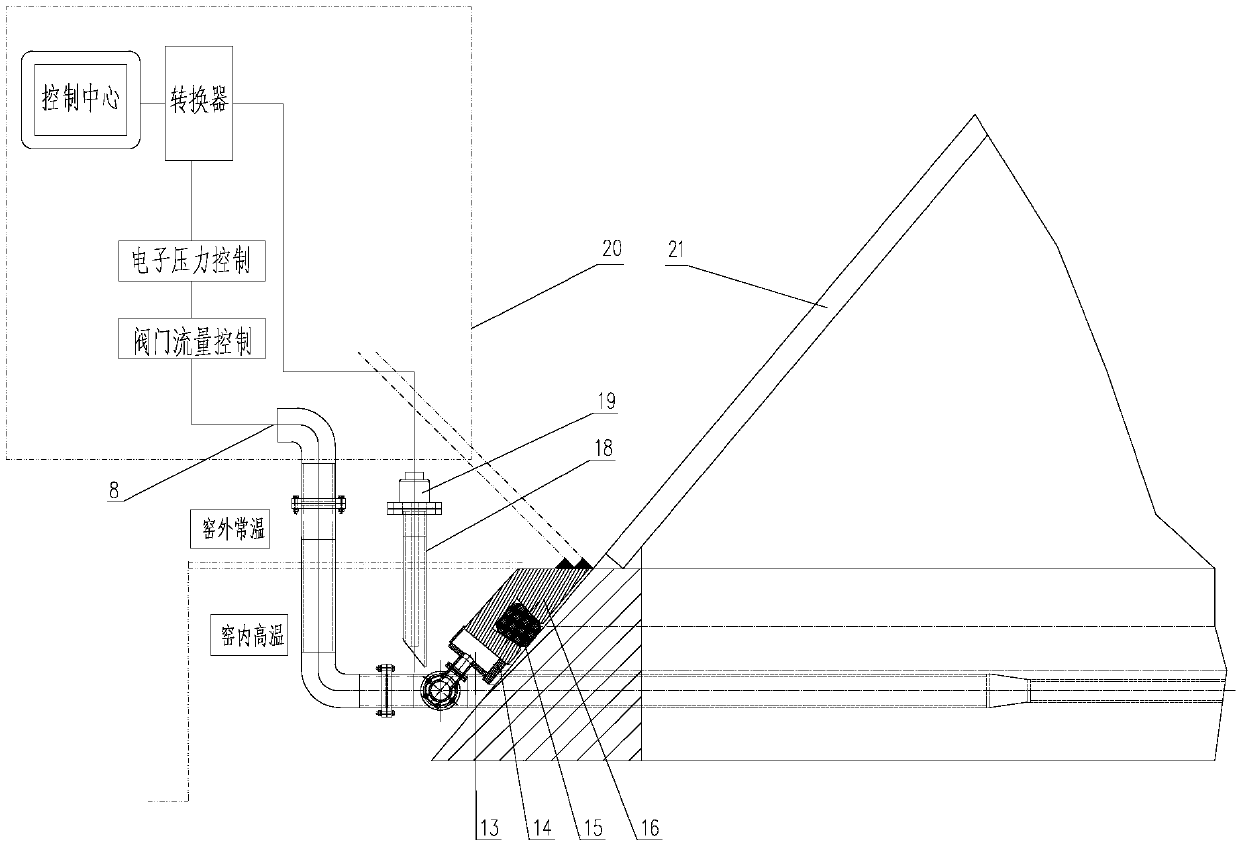

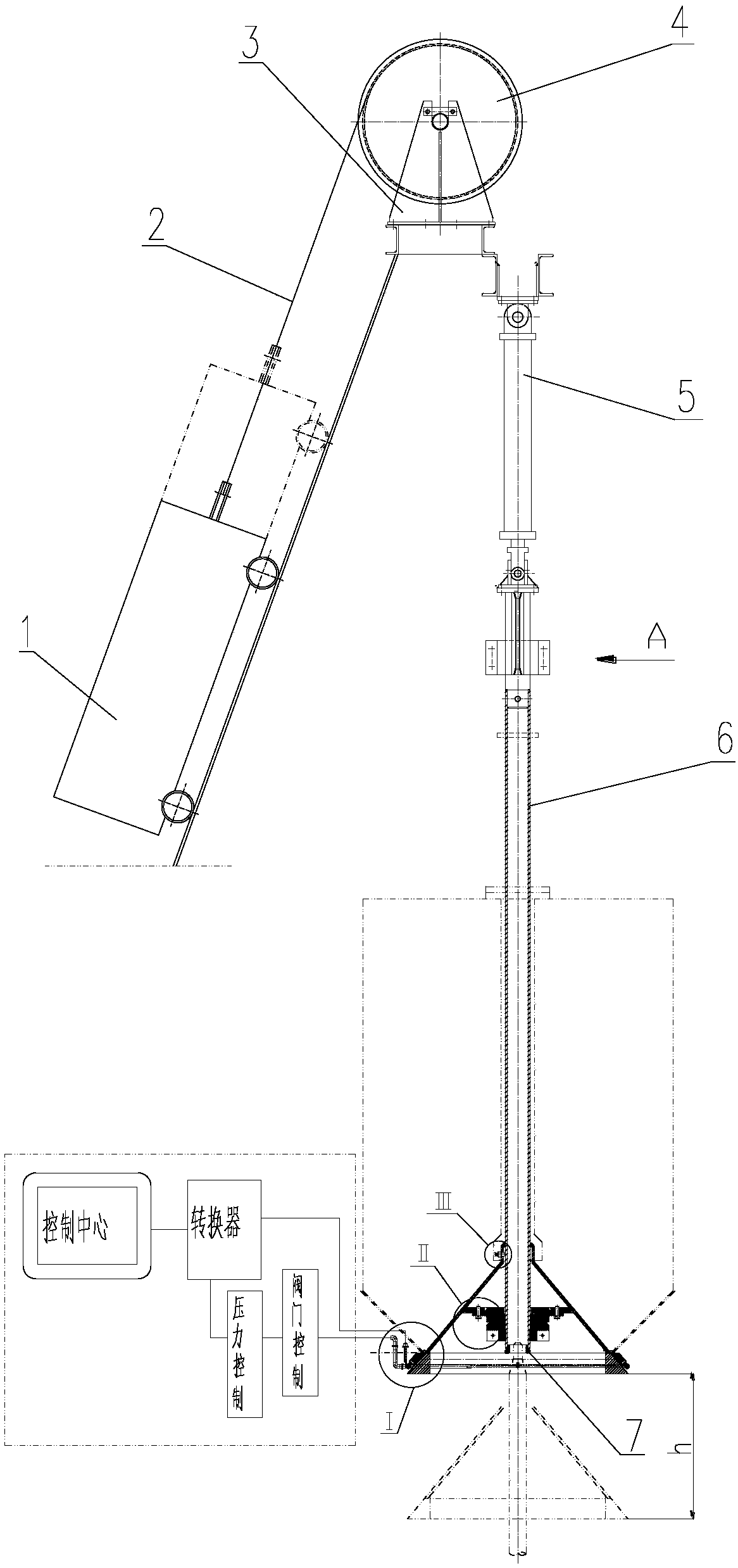

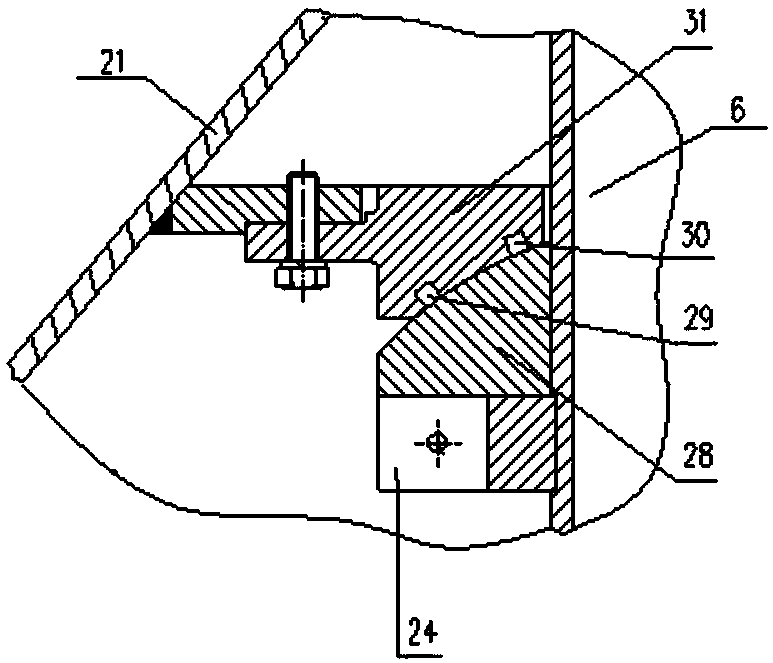

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0024] Such as Figure 1 to Figure 5 As shown in the present invention, a lime double-chamber vertical kiln kiln feeding boom device includes a counterweight system, a hydraulic cylinder 5, a boom 6, a boom upper fixing device 35, a guide frame 34, and a fixed guide rail 32 , limit switch 33, end seal structure and air supply cooling system, the counterweight system is made up of counterweight vehicle 1, steel wire rope 2, fixed support 3, sheave 4, wherein one end of steel wire rope 2 is connected with counterweight vehicle 1, the other One end passes through the rope pulley 4 installed on the fixed bracket 3 and is connected with the guide frame 34, and the guide frame 34 can reciprocate up and down along the fixed guide rail 32; the base end of the hydraulic cylinder 5 is fixed, and the hydraulic rod end is connected with the guide frame 34; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com