A Method of Measuring the Radial Flow Gap of Steam Turbine by Laser Tracking Measurement System

A technology of laser tracking measurement and system measurement, which is applied in the field of steam turbines to achieve the effects of shortening the maintenance period, improving data accuracy and reducing manual workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

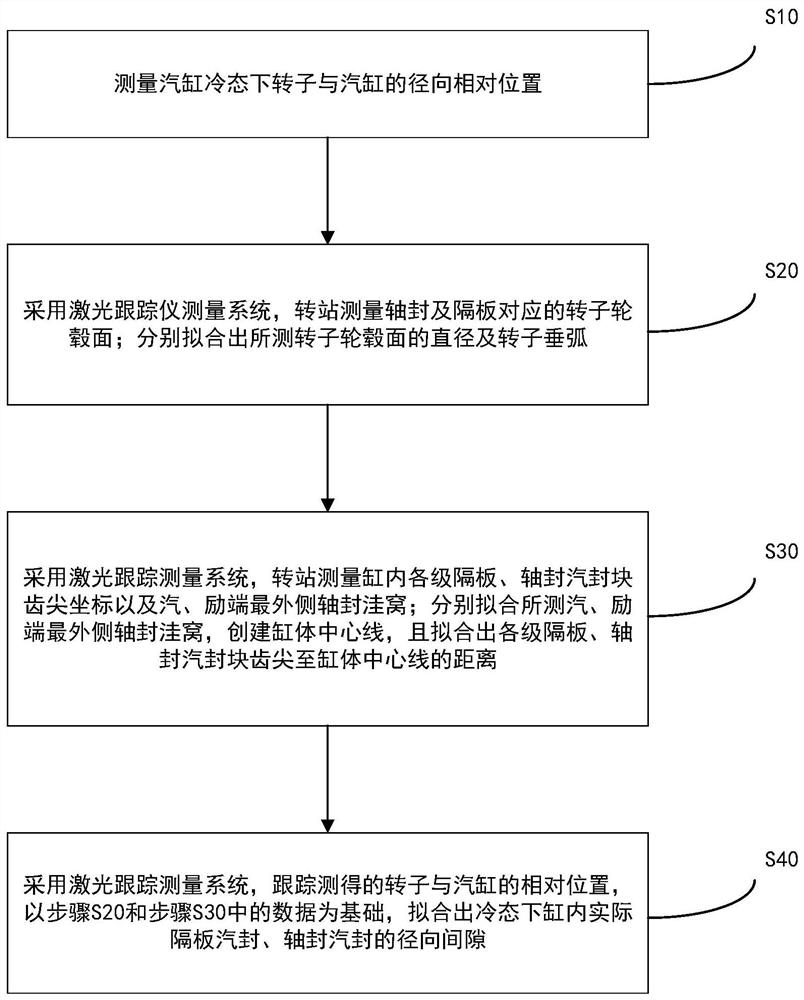

Method used

Image

Examples

Embodiment Construction

[0048] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

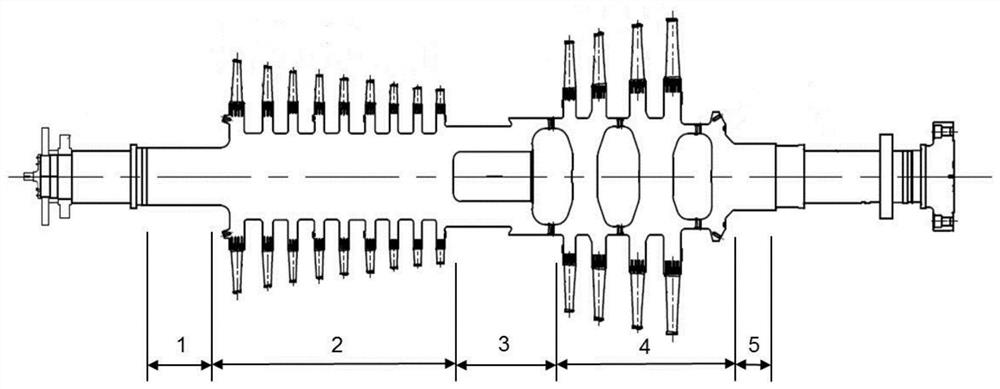

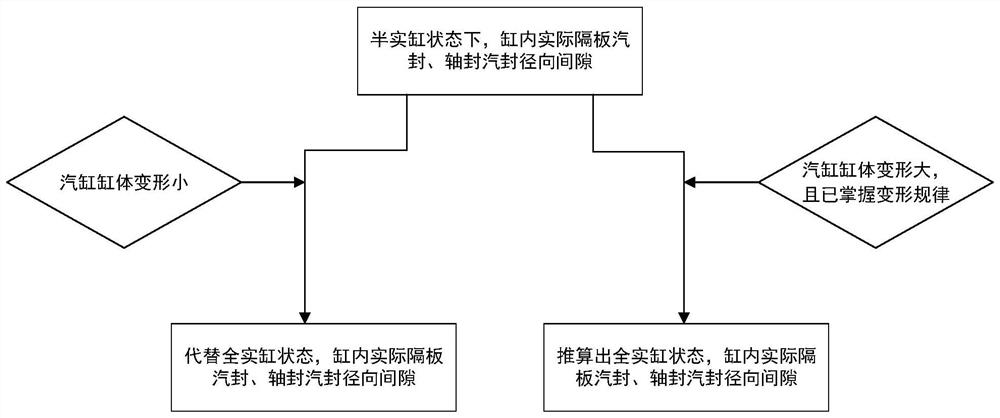

[0049] The invention uses a laser tracker to measure the center line of the rotor, the inner diameter of the hub, and the vertical arc of the rotor, and measures the center line of the cylinder body in the cylinder under the state of being completely empty, the distance from the diaphragm seal teeth to the center line of the cylinder body, and the shaft seal seal. The distance from the teeth to the center line of the cylinder body, etc., according to the relative position of the rotor and the cylinder when disassembled, analyzed and processed the above measurement data, and fitted the actual flow gap in the cylinder under the cold state of the full solid cylinder. The invention can also dismantle the cylinder to the half...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com