LED lamp

A technology of LED lamps and LED chips, which is applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of inability to dissipate heat from thermal fluid and low heat dissipation effect of LED lamps, and achieve improved heat dissipation and heat dissipation The effect is obvious and the effect of delaying the return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

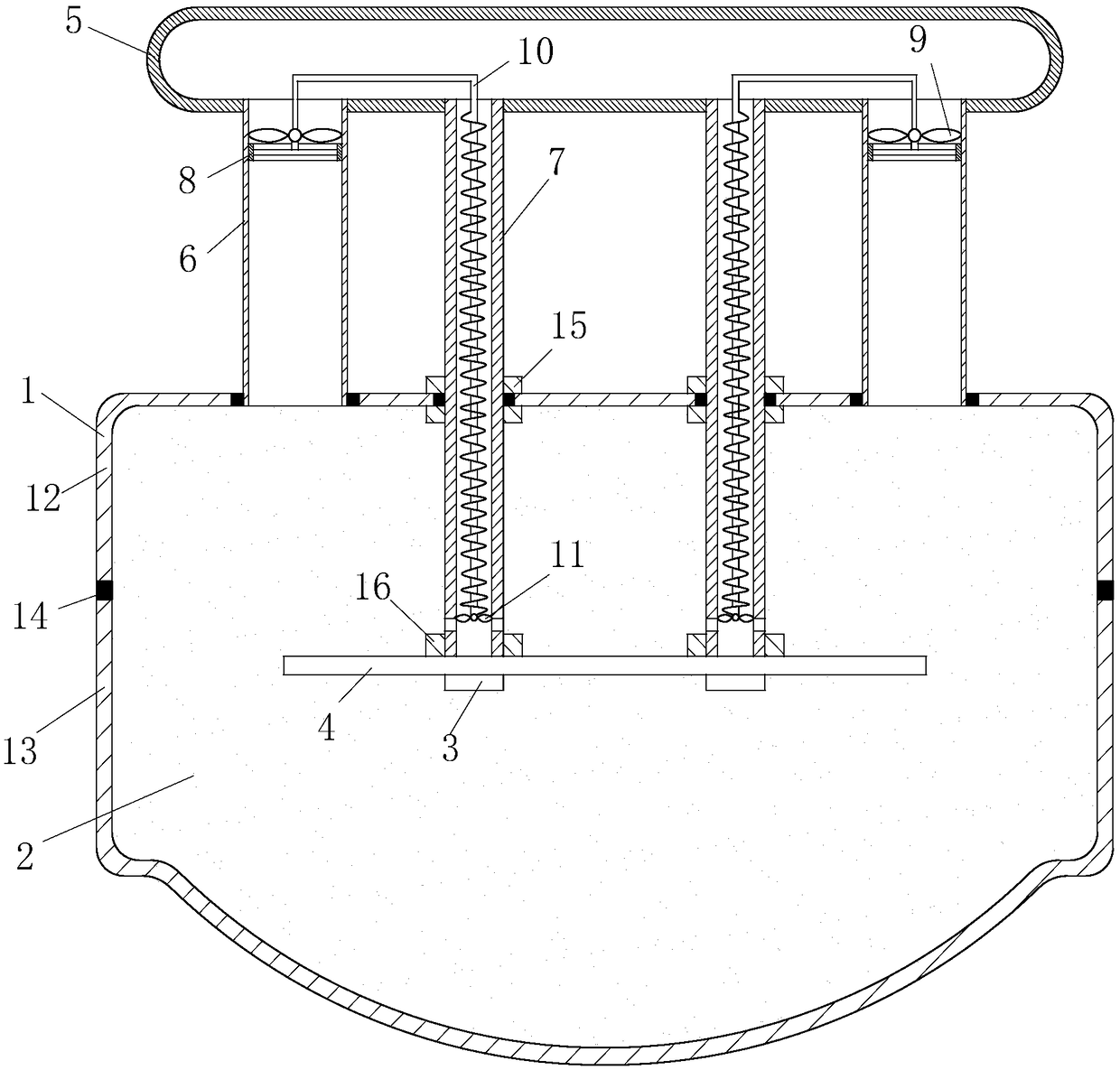

[0021] As an embodiment of the present invention, the metal substrate 4 and the return pipe 7 are fixedly connected by the No. 2 nut 16, and the No. 2 nut 16 is fixed on the upper end surface of the metal substrate 4. Tube 7 is locked.

[0022]As an embodiment of the present invention, the flexible shaft 10 is made of soft material. When the large fan 9 rotates, the soft shaft 10 is driven to rotate in a spiral shape, and the flexible shaft 10 returns to its original state to rotate, and then drives the small fan 11 to rotate. The part of the soft material located in the return pipe 7 is provided with a helical thread, and when the flexible shaft 10 rotates, the helical thread can delay the return velocity and speed up the gas flow rate, thereby achieving the effect of cooling the heat transfer fluid 2.

[0023] As an embodiment of the present invention, the inner diameter of the outlet pipe 6 is larger than the inner diameter of the return pipe 7 , which can ensure that the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com