Charge structure for improving shaped charge penetration speed

A technology of shaped charge and speed, applied in blasting and other directions, can solve the problems of low jet velocity and small penetration depth, and achieve the effect of increasing penetration depth, increasing penetration speed, and strengthening the driving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

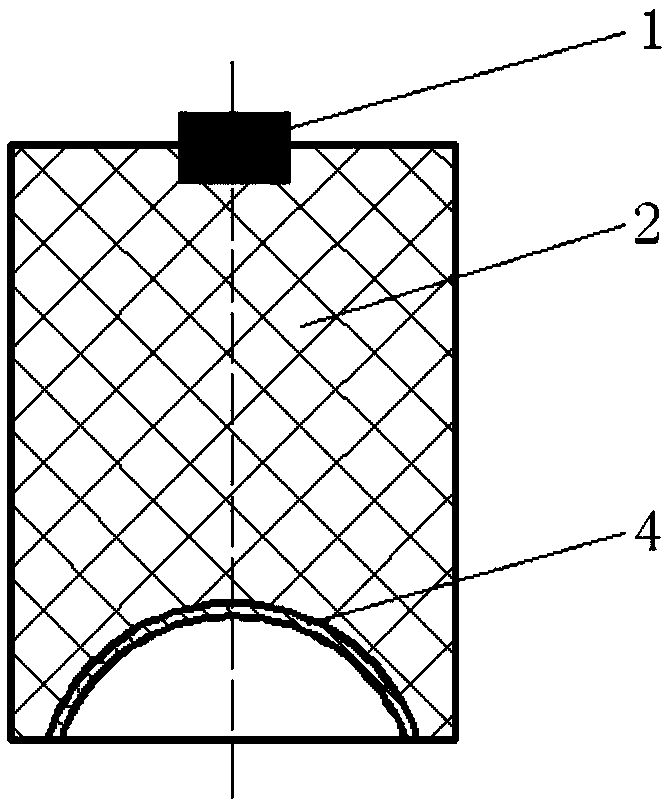

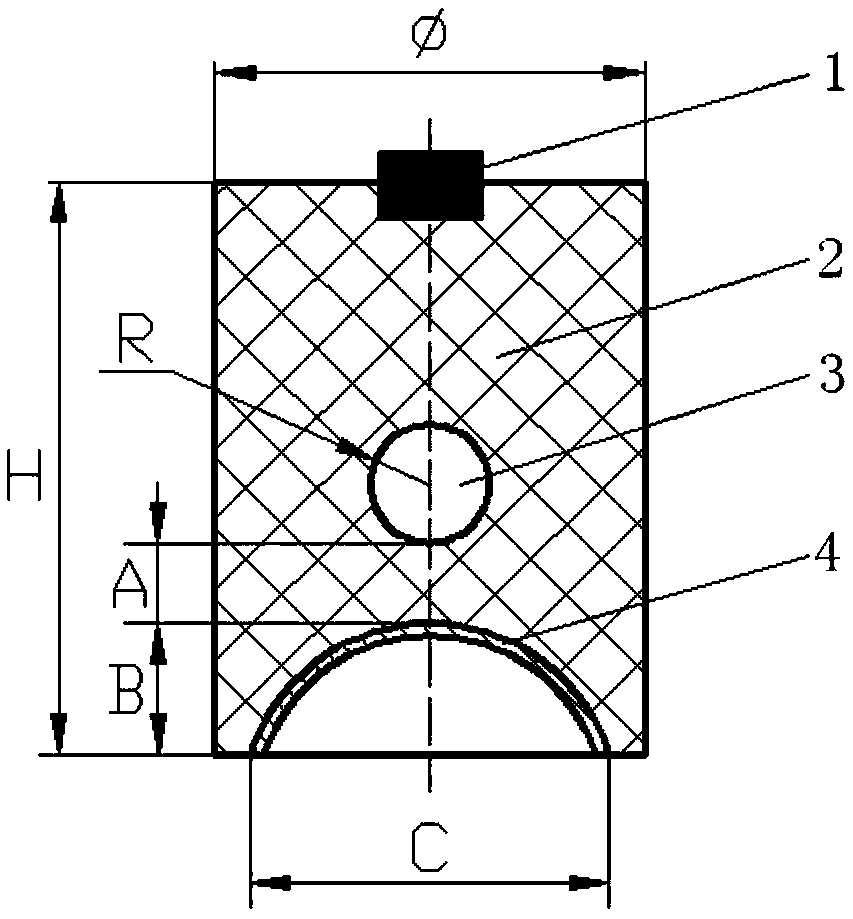

[0013] see Figure 2-Figure 3 , a shaped charge structure that can increase the penetration speed, including a detonator 1, an explosive 2, a cavity 3 and a charge cover 4. The cavity 3 is located on the central axis of the charge, and is spherical with a radius of R. The overall size of the shaped charge is φ×H. The size of the mouth of the drug-shaped cover 4 is C, and the height is B. The distance between the lower part of the cavity 3 and the charge is Cover 4 top is A. When H=(1.2~1.5)φ, the size and position relationship of the hole 3 satisfies: R=(1 / 9~1 / 7)φ, R=(0.4~0.6)A, the penetration speed can be effectively improved, At the same time, the penetration hole diameter is not reduced.

[0014] The charging method is explained step by step as follows:

[0015] a) When the press-packing process is used to charge the powder, the following sub-steps are included:

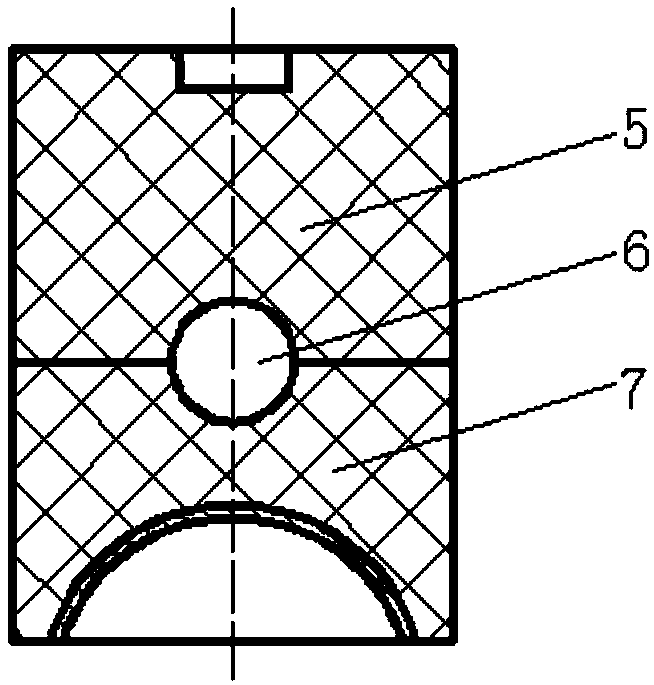

[0016] Sub-step 1: Make the spherical mold 6 for the hollow ball 3, and make the shell mold for the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com