Three-dimensional unsteady slurry grouting test device and method

A grouting test, an unsteady technology, applied in the direction of measuring devices, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve the problem of not being able to reflect the diffusion law of grout, not considering the performance parameters of grout, and not being able to observe the grout of the device in real time Diffusion flow and the expansion process of cracks, etc., to achieve the effect of easy direct observation, good promotion prospects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

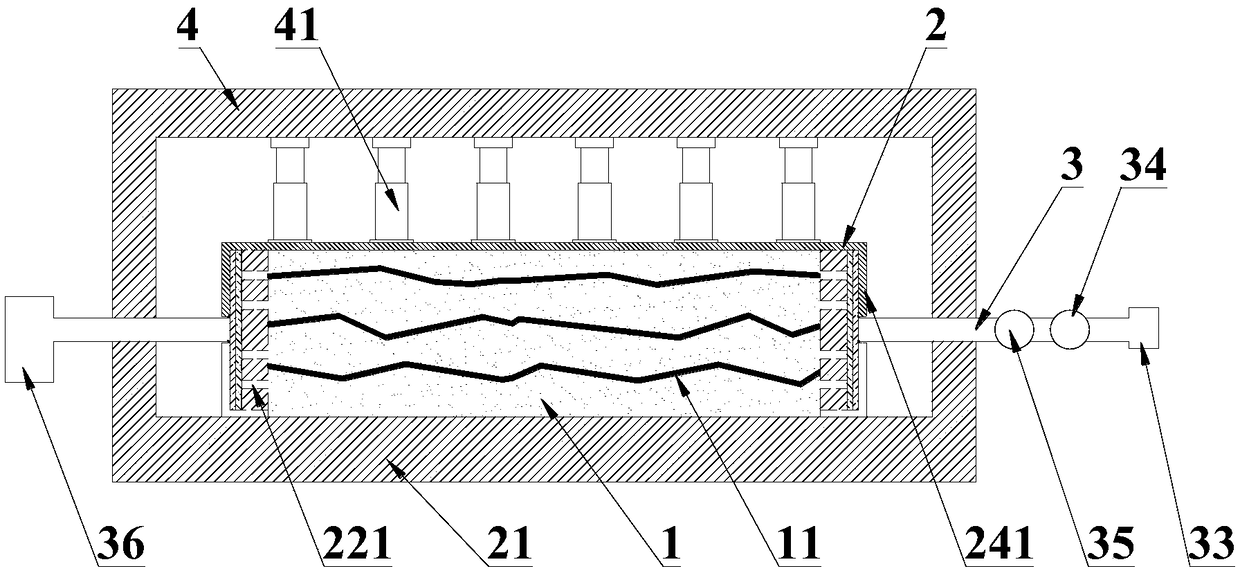

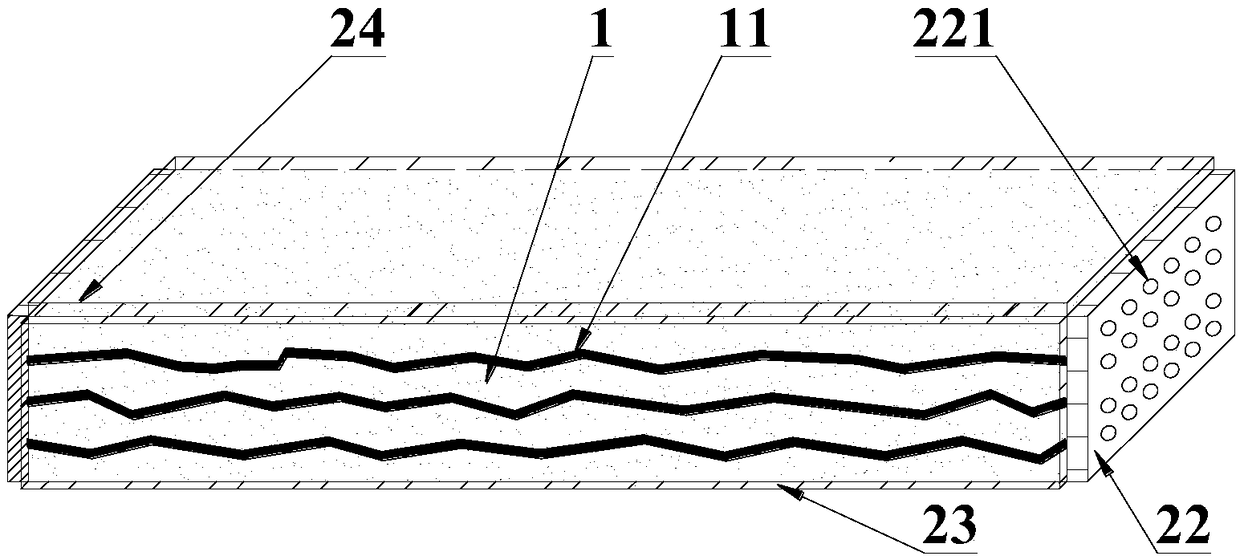

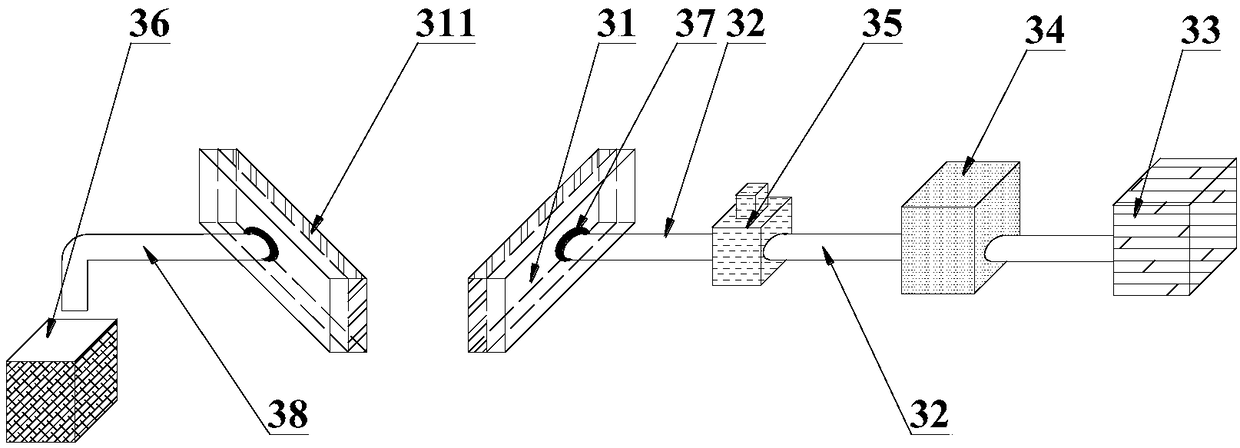

[0025] like figure 1 As shown, a three-dimensional unsteady grouting test device includes a fixing and loading system 2 that closes and accommodates a rock mass sample 1, and a grouting system 3 that cooperates with the fixing and loading system 2 to provide grout for the rock mass sample 1 The rock mass sample 1 has a crack 11, and the fixing and loading system 2 can directly observe the internal rock mass sample 1. The grouting system 3 provides grout for the rock mass sample 1 fixed in the fixing and loading system 2, and the grout flows along the crack 11, and the grouting flow process of the grout can be directly observed through the fixing and loading system 2, which is convenient for obtaining the grout Diffusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com