Method of quantitatively detecting pipeline defects based on ultrasonic guided waves

A technology for detecting pipelines and ultrasonic guided waves, which is applied in the direction of material analysis using sound waves/ultrasonic waves/infrasonic waves, processing detection response signals, measuring devices, etc., and can solve problems such as difficulties in solving basic solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

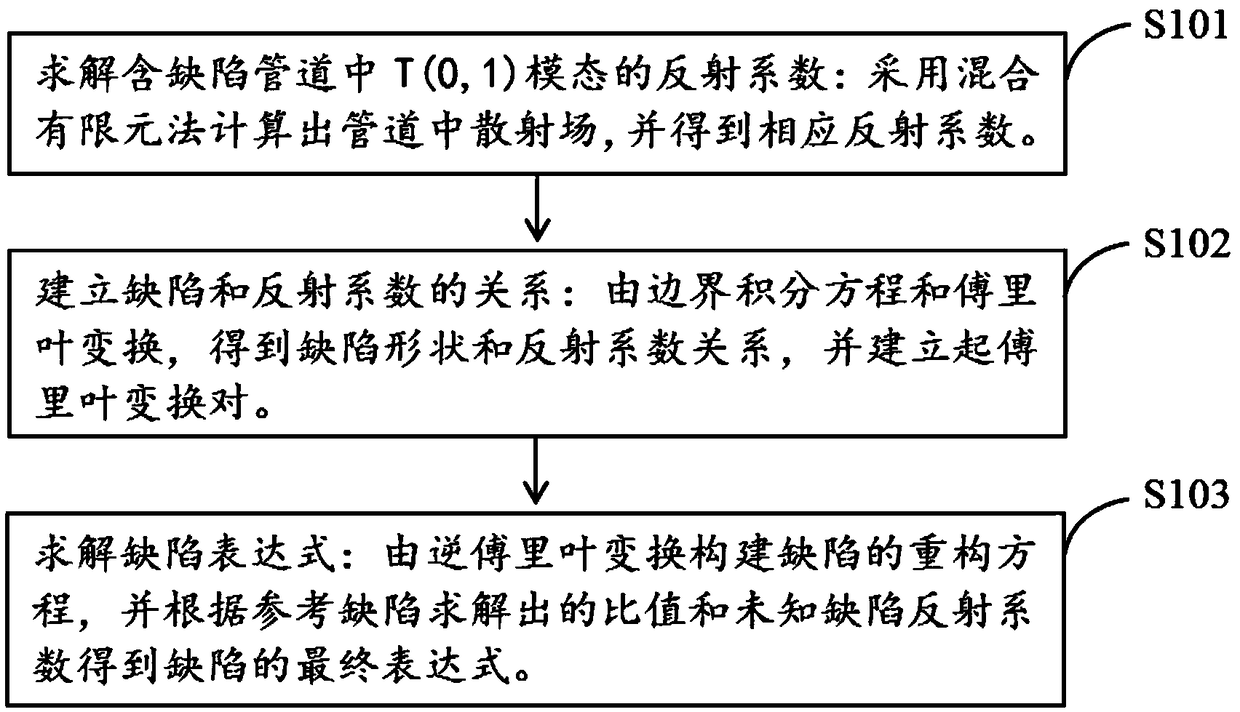

Method used

Image

Examples

Embodiment 1

[0145] Example 1: Investigating the influence of different reference defects on the reconstruction results of unknown rectangular defects:

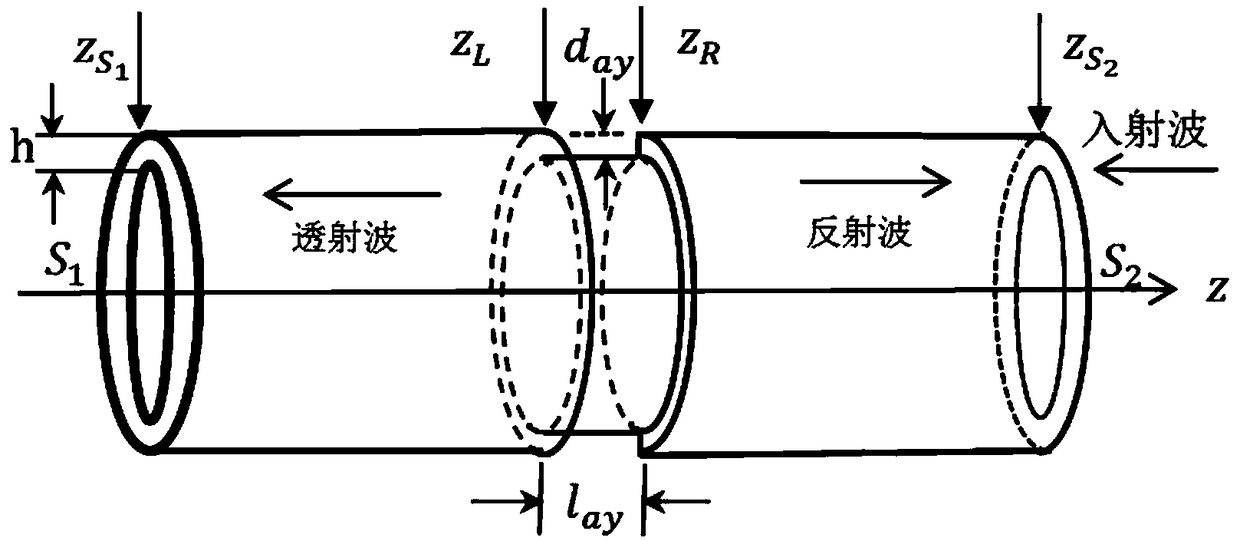

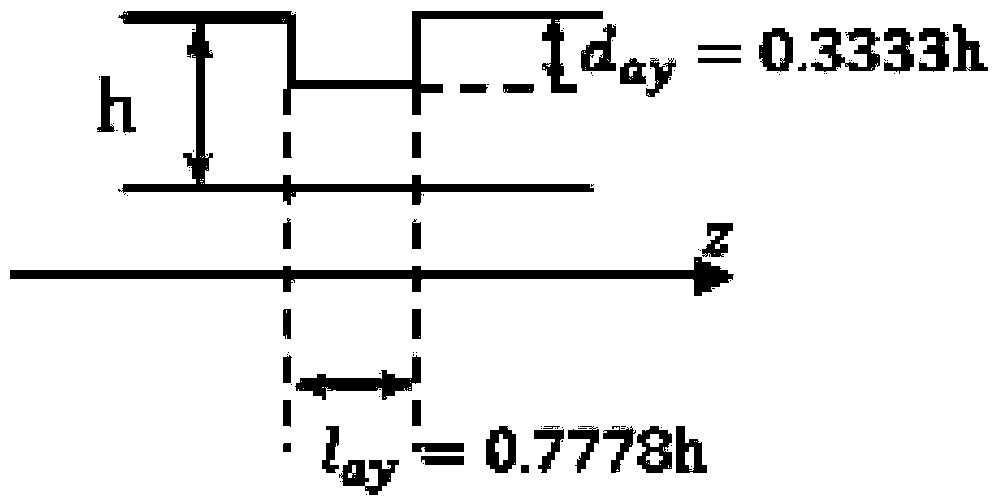

[0146] Figure 5a , Figure 5b , Figure 5c and Figure 5d It is a schematic diagram of defects to be reconstructed (or known as unknown defects), in the figure d ay and l ay Denote the depth and width of an axisymmetric defect, respectively. according to Figure 4The reflection coefficients of different reference defects in , reconstructed Figure 5a medium rectangle defect, the result is as Figure 6 shown. apparently based on Figure 3a The reconstruction result of the reference defect (the first kind of reference defect) is closer to the actual defect shape, but no matter what kind of reference defect is used, the actual defect can be effectively reconstructed.

Embodiment 2

[0147] Example 2: Investigating the influence of different reference defects on the reconstruction results of unknown ladder-shaped defects:

[0148] pass Figure 3a , Figure 3b , Figure 3c Two-step and five-step defects (such as Figure 5b and Figure 5c ) for reconstruction, the result is as follows Figure 7 and Figure 8 shown. Figure 7 According to Figure 3b (The second reference defect) The reconstructed result is closer to the double-ladder defect, Figure 8 shown in the Figure 3a (The first kind of reference defect) The reconstructed result is closer to the five-step defect.

Embodiment 3

[0149] Example 3: Investigating the influence of different reference defects on the reconstruction results of unknown double rectangle defects:

[0150] Figure 9 The reconstruction results of double-rectangular defects are shown. Because double-rectangle defects are more complex in reconstruction, the reconstruction results of different reference defects are quite different, but they can all reflect the number and size of defects. According to the reference defect Figure 3b (The second type of reference defect) The shape of the reconstructed defect is more consistent with the actual defect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com