Calculating method for dilution ratio of reaction liquid while researching nucleation rate of ion crystallization reaction

A technology of ion crystallization and nucleation rate, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of not giving the calculation method of dilution factor or the way to obtain it, and affecting the accuracy of the nucleation rate of ion crystallization reaction, so as to reduce The number of experiments, saving time, and the effect of simple calculation formulas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Prepare a certain volume of 0.1mol / L hydrazine nitrate + 0.05, 0.07, 0.09, 0.15, 0.20, 0.30mol / LH 2 SO 4 +0.1mol / L oxalic acid as diluent.

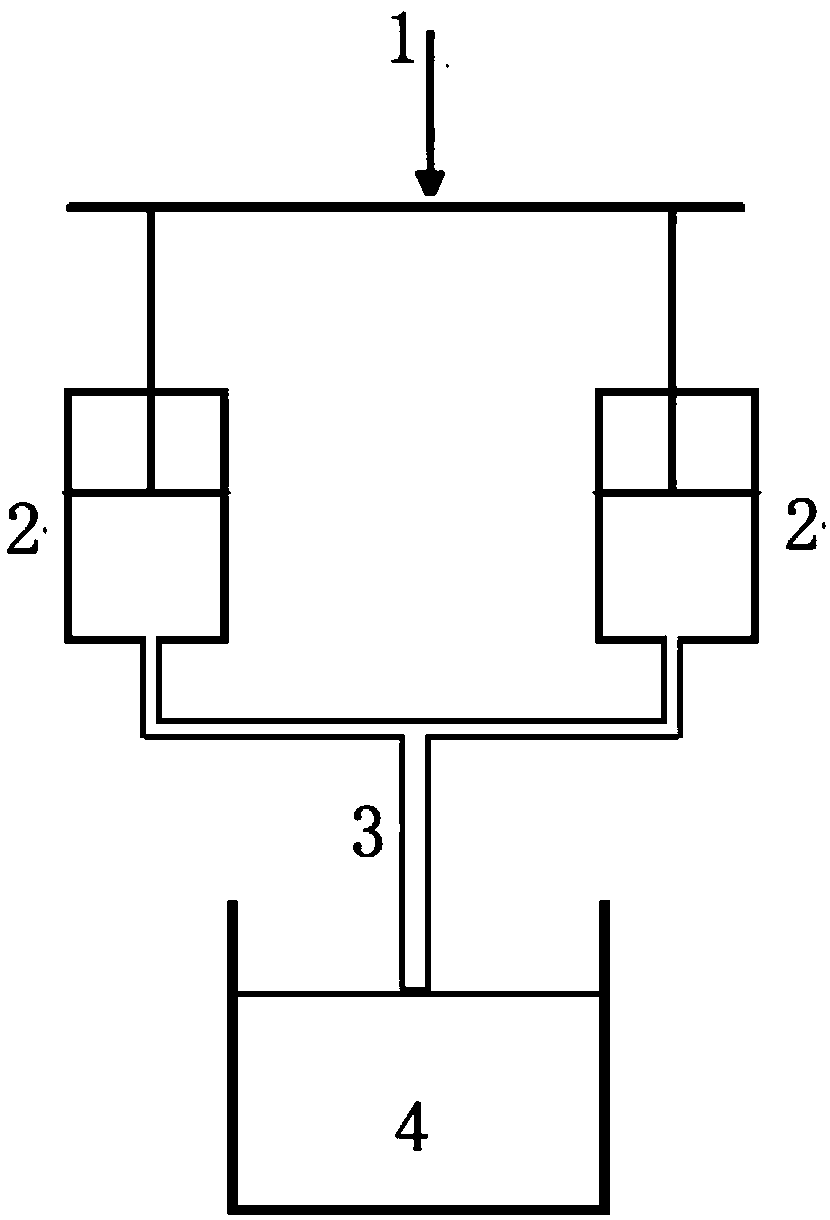

[0027] 2) At 25°C, 15.0 mL of the first reaction solution (0.05, 0.07, 0.09, 0.15, 0.20, 0.30 mol / L ferrous sulfate+0.1 mol / L hydrazine nitrate solution) and 15.0 mL of the second reaction solution were respectively reacted. Liquid (corresponding to 0.25, 0.27, 0.29, 0.35, 0.40, 0.50mol / L oxalic acid + 0.1mol / L hydrazine nitrate solution) was added to figure 1 Two feeders 2 are shown.

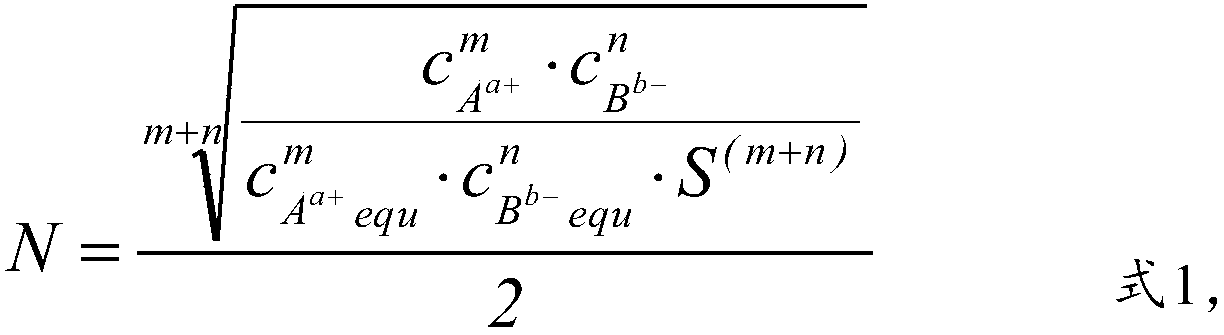

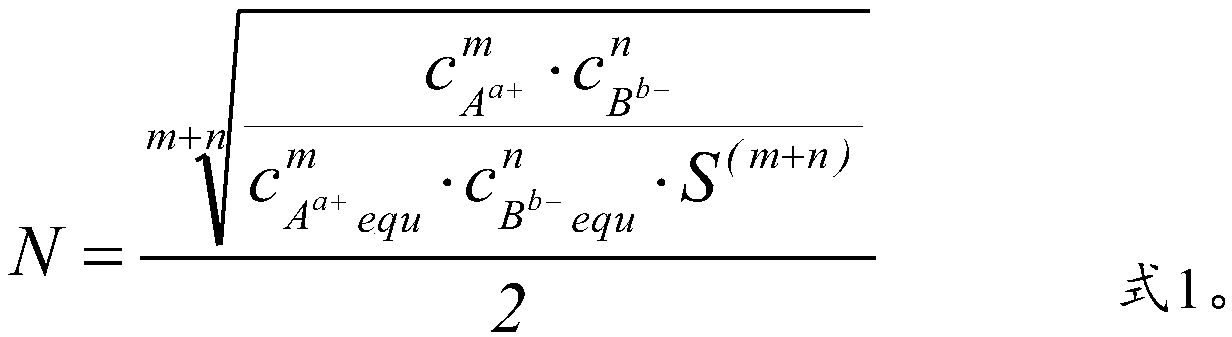

[0028] 3) On the basis of measuring the relevant concentration values (C Aa+ is the concentration of ferrous sulfate in the first reaction solution, C Bb- is the concentration of oxalic acid in the second reaction solution; at a constant temperature of 25 °C, after mixing the first reaction solution and the second reaction solution in equal volumes in a beaker until the equilibrium of dissolution and precipitation is reached, measure the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com