Magnetic closed ignition coil

An ignition coil, closed magnetic technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor core, transformer, etc., can solve the problems of affecting engine power, insufficient secondary ignition energy, etc., to achieve ignition Reliable and stable, improved performance, full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments,

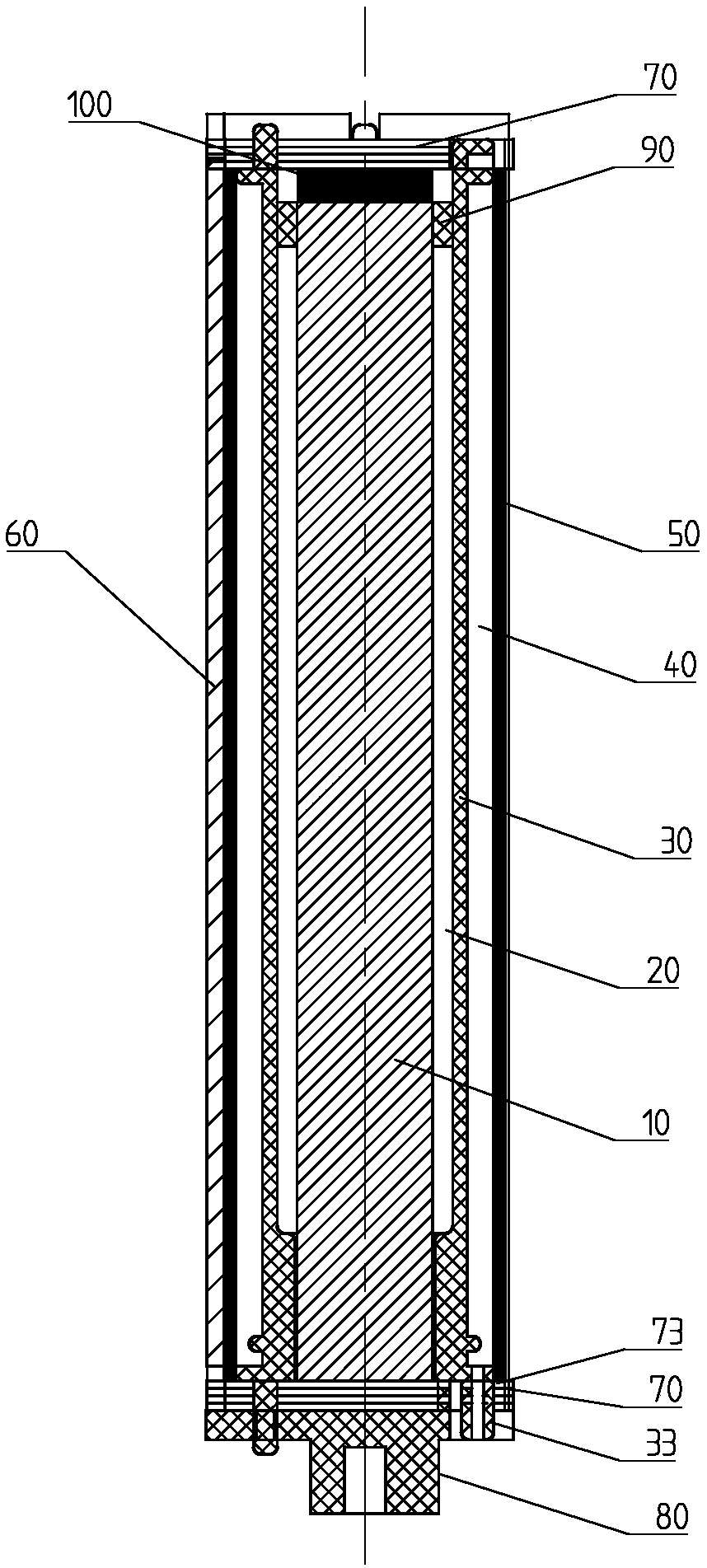

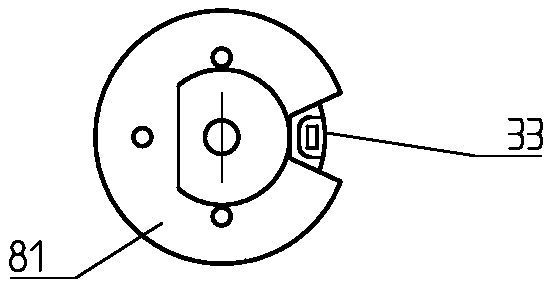

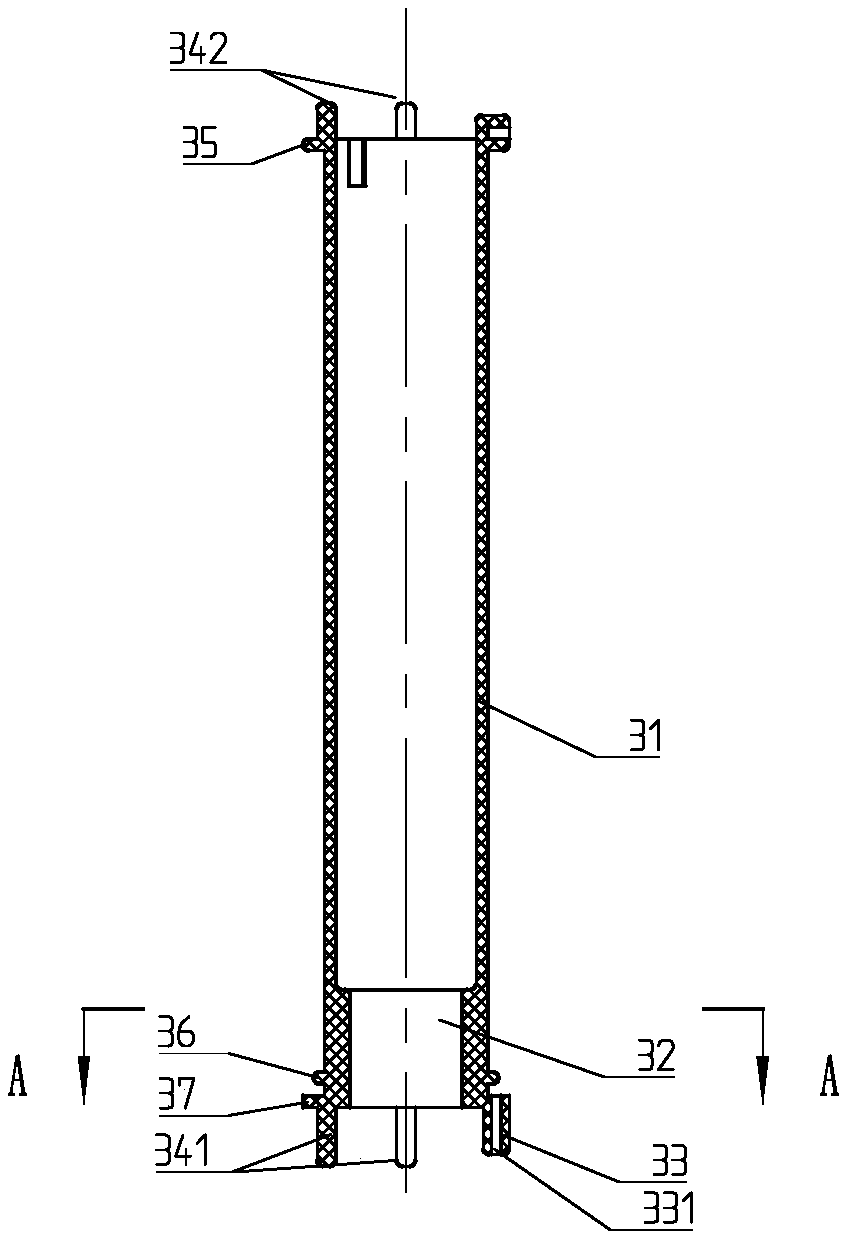

[0035] A closed magnetic ignition coil, comprising an iron core 10, a primary winding 20 wound on the peripheral surface of the iron core 10 and arranged axially, a high-voltage bobbin 30 sleeved outside the primary winding 20, and wound on the high-voltage bobbin 30 The secondary winding 40, the ceramic sleeve 60 set on the secondary winding 40, the two ends of the ceramic sleeve 60 are fitted with a magnetically conductive cover 70 and the two ends of the iron core 10 are attached to the two magnetically conductive covers 70, form a closed magnetic circuit.

[0036] A magnetic steel 100 is clamped between one end of the iron core 10 and the magnetically permeable cover 70 at the corresponding end, and the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com