Plasma ejection igniter

A plasma and igniter technology, used in weapon accessories, fuzes, offensive equipment, etc., can solve the problems of long ignition time, slow reaction speed, easy to detonate, etc., and achieve high ignition energy, long action time, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Now, the present invention will be described in detail in conjunction with the embodiments shown in the accompanying drawings.

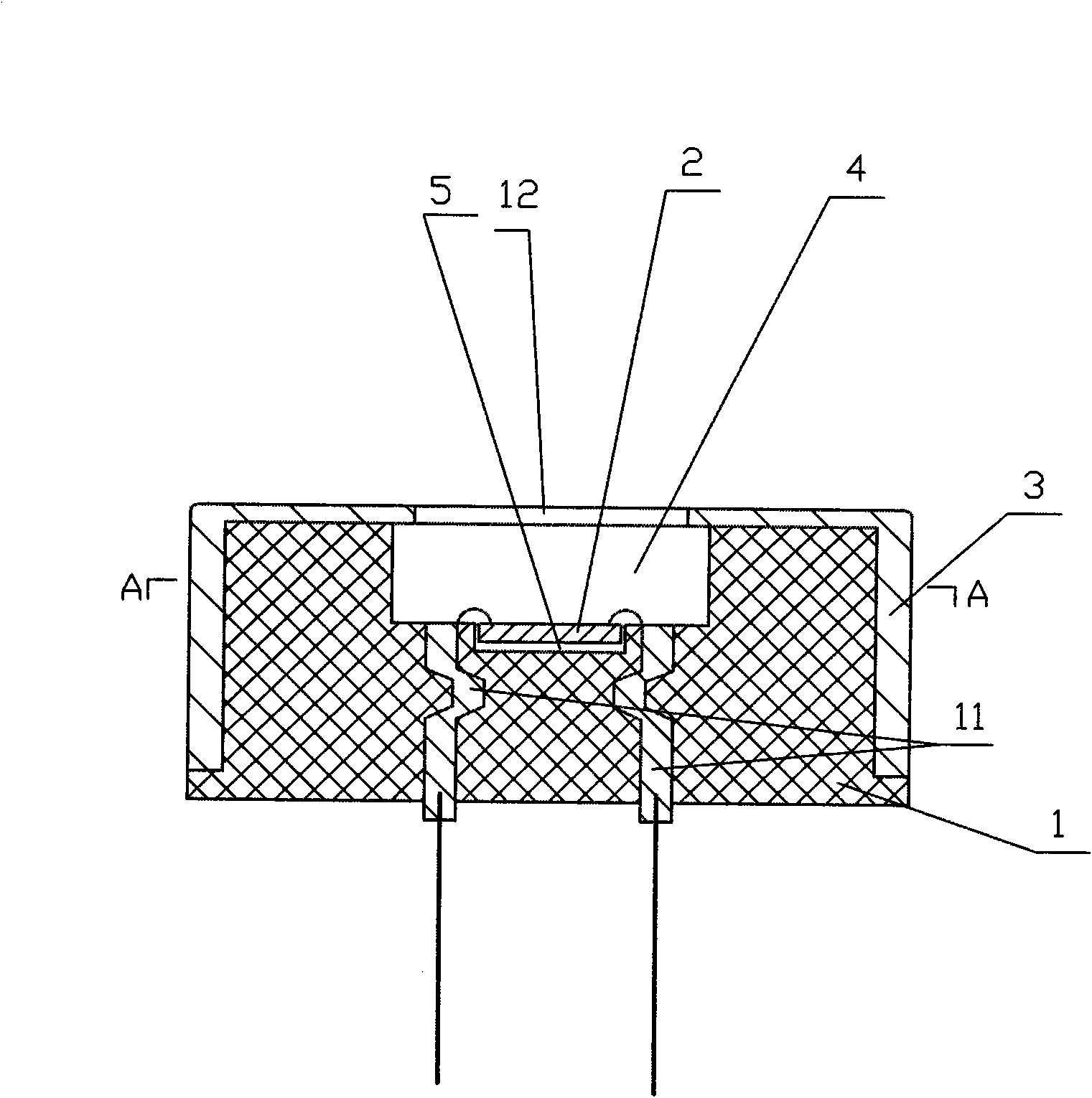

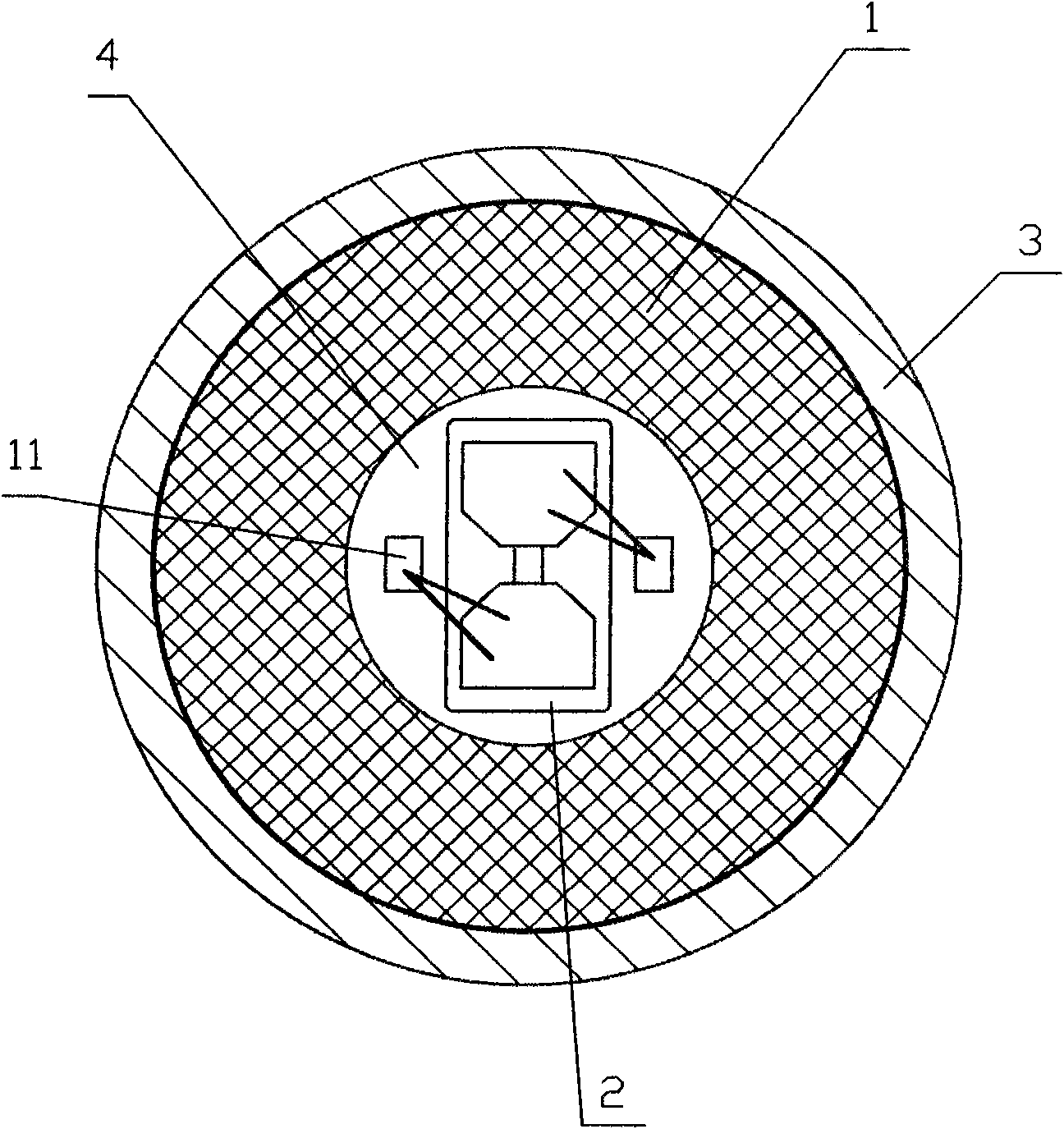

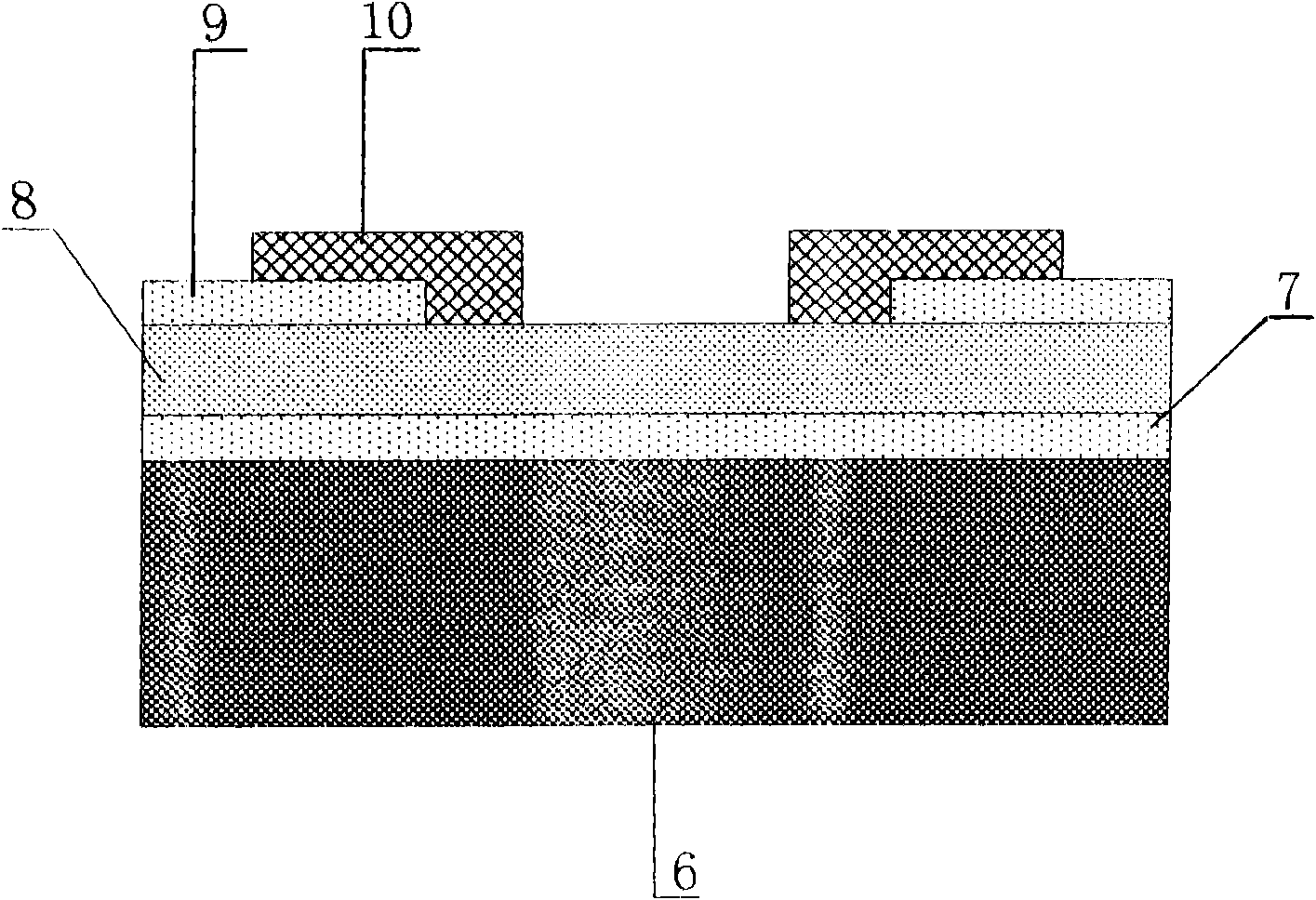

[0010] As shown in the figure, the plasma jet igniter is composed of an inverted cylinder-shaped double-pit injection molding base 1, a polysilicon plasma ignition chip 2, and an outer shield 3. Pit 4, square lower pit 5, polysilicon plasma ignition chip 2 from bottom to top are monocrystalline silicon substrate 6, insulating dielectric bottom layer 7, polysilicon mass block 8 with thin film layer outside, insulating dielectric layer 9, metal thin film electrode The pad 10 and the chip 2 are bonded in the lower pit 5 in the base 1, and the flat curved electrode guide 11 is drawn out through the inner cavity of the lower part of the base 1, and the chip 2 and the electrode guide 11 are packaged in the base 1 , the top surface of the outer shield 3 corresponding to the pit of the base 1 is provided with a flame spout 12, which is clamped outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com