Metal magnetic lining plate formed by reinforcing protective layer

A technology to strengthen the protective layer and metal magnetism, which is applied in the direction of grain processing, etc., can solve the problems of weakening the wear resistance of the magnetic lining, weakening the firmness of the protective layer⑾, and shortening the service life, so as to prolong the service life and reduce the leakage of ore slurry , The effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

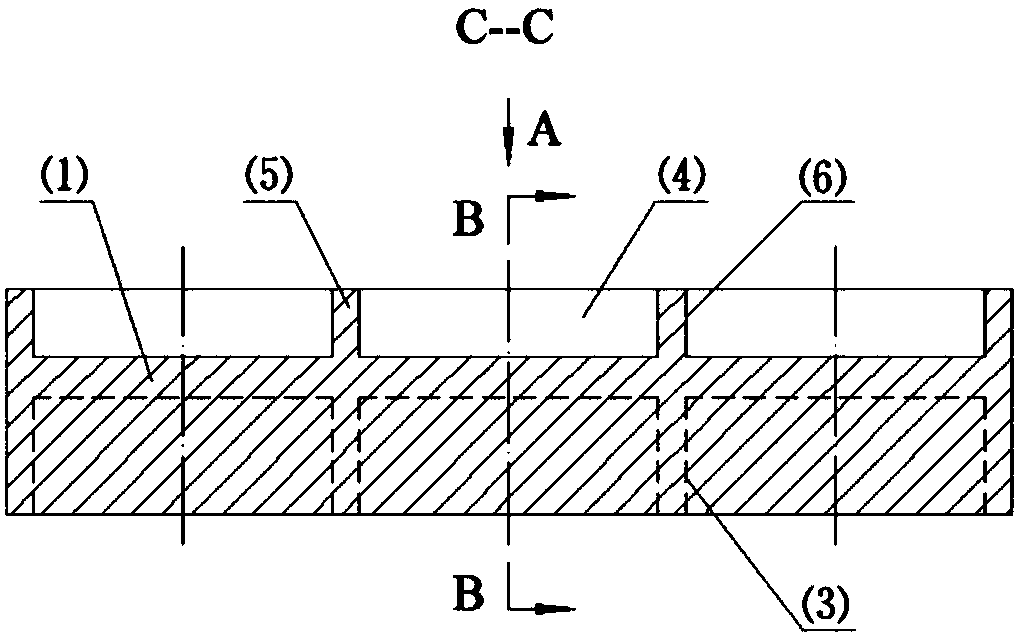

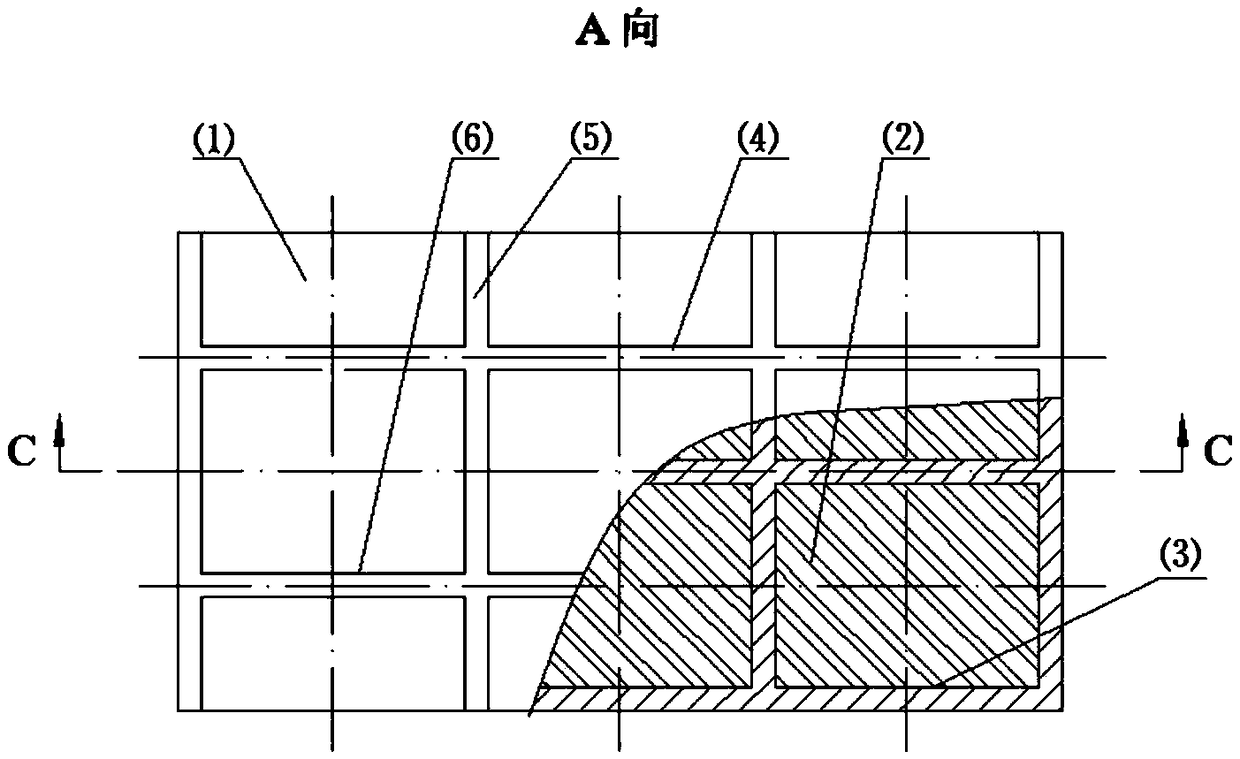

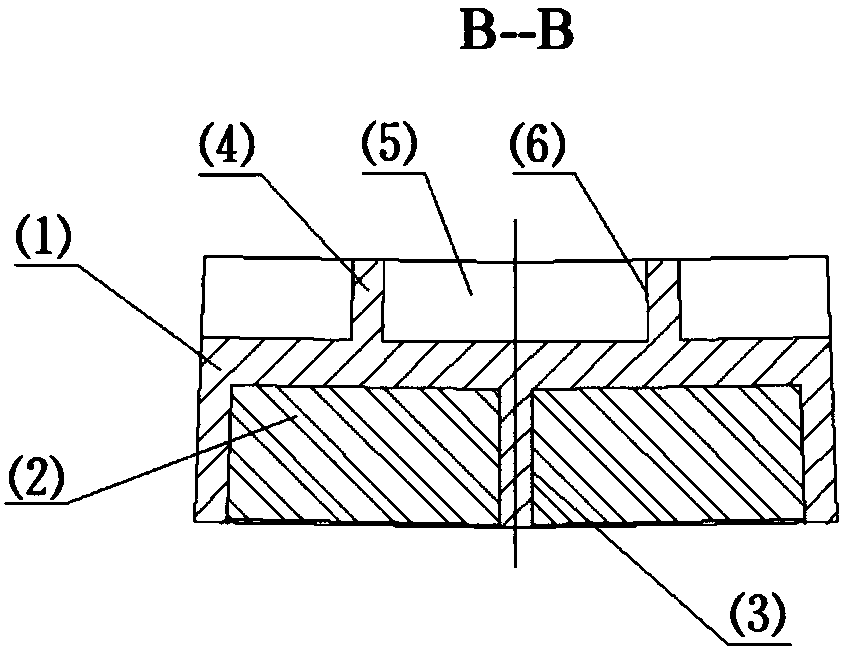

[0047] The second overflow type ball mill, the specification is Φ3.6m×6.0m. The material is magnetite, and the diameter of the steel ball is ≤60mm. A metal magnetic liner formed by a reinforced protective layer of the present invention adopting the basic structure, such as Figure 1 ~ Figure 3 shown.

[0048] The magnetic liner is composed of the shell ⑴, the magnetic block group ⑵ and the adhesive. The shell (1) is cast according to the chemical composition of non-magnetic steel. One side is the installation surface, which is composed of 6 cube-shaped lattices (3) arranged in 2 rows and 3 columns; the other side is the working surface, which consists of 2 pole ribs (4) and 4 transverse ribs. Plates (5) enclose shallow grooves (6), polar ribs (4) are located in the symmetrical center plane of each row of grids (3), transverse ribs (5) are perpendicular to polar ribs (4), and are aligned with the side walls of grids (3). Each magnetic block group ⑵ is composed of 2 ferrite m...

Embodiment 2

[0052] The second stage of overflow ball mill, specification Φ5.0m×6.5m. The material is magnetite, and the diameter of the steel ball is ≤60mm. A metal magnetic liner formed by a reinforced protective layer of the present invention that adopts an inlaid hemispherical magnetizer (7), such as Figure 4 ~ Figure 6 shown.

[0053] The magnetic liner is composed of the shell ⑴, the magnetic block group ⑵ and the adhesive. First cast the magnetizer (⑺) according to the chemical composition of the wear-resistant magnetic steel, and then cast the shell (1) according to the chemical composition of the non-magnetic steel, and cast the magnetizer (7) on it during the process of casting the shell (1). Heat treatment is carried out using a process suitable for both the shell (1) and the magnetizer (7). One side of the housing (1) is the mounting surface, which consists of 6 cube-shaped grids (3) arranged in 2 rows and 3 columns; the other side is the working surface, the magnetizer (7)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com