3D sculpturing garment manufacturing method and system thereof

A production method and sculpture technology, applied to sewing tools, special data processing applications, instruments, etc., can solve the problems of clothing design complexity, increased clothing production costs, and the inability to effectively meet customer clothing customization needs , to achieve the effects of shortening the proofing time, smooth communication and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described below through specific specific examples, and those who are familiar with this technology can easily understand other advantages and technical effects of the present invention from the content disclosed in this description, and can also be improved by other different specific examples. implement or apply.

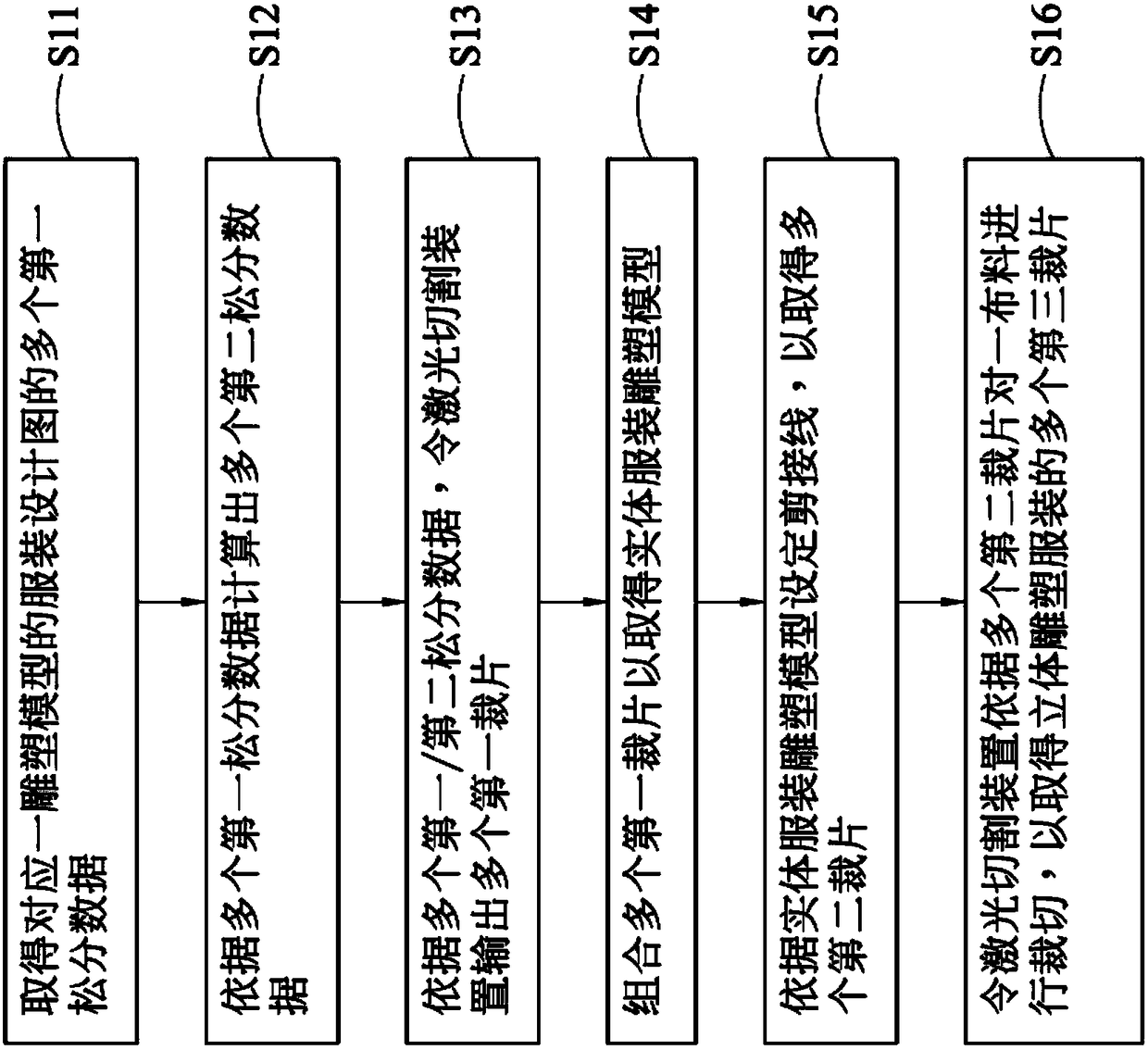

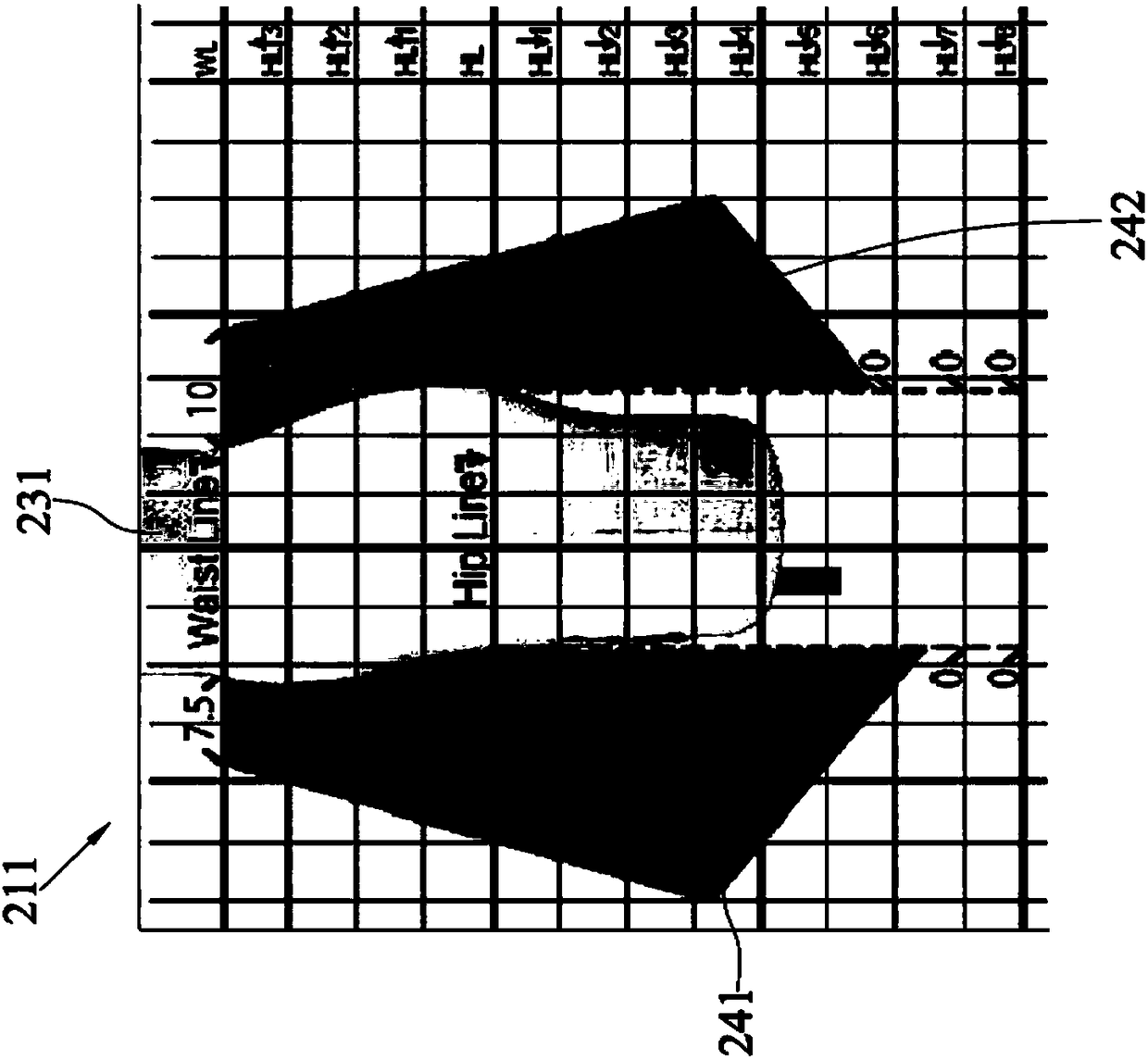

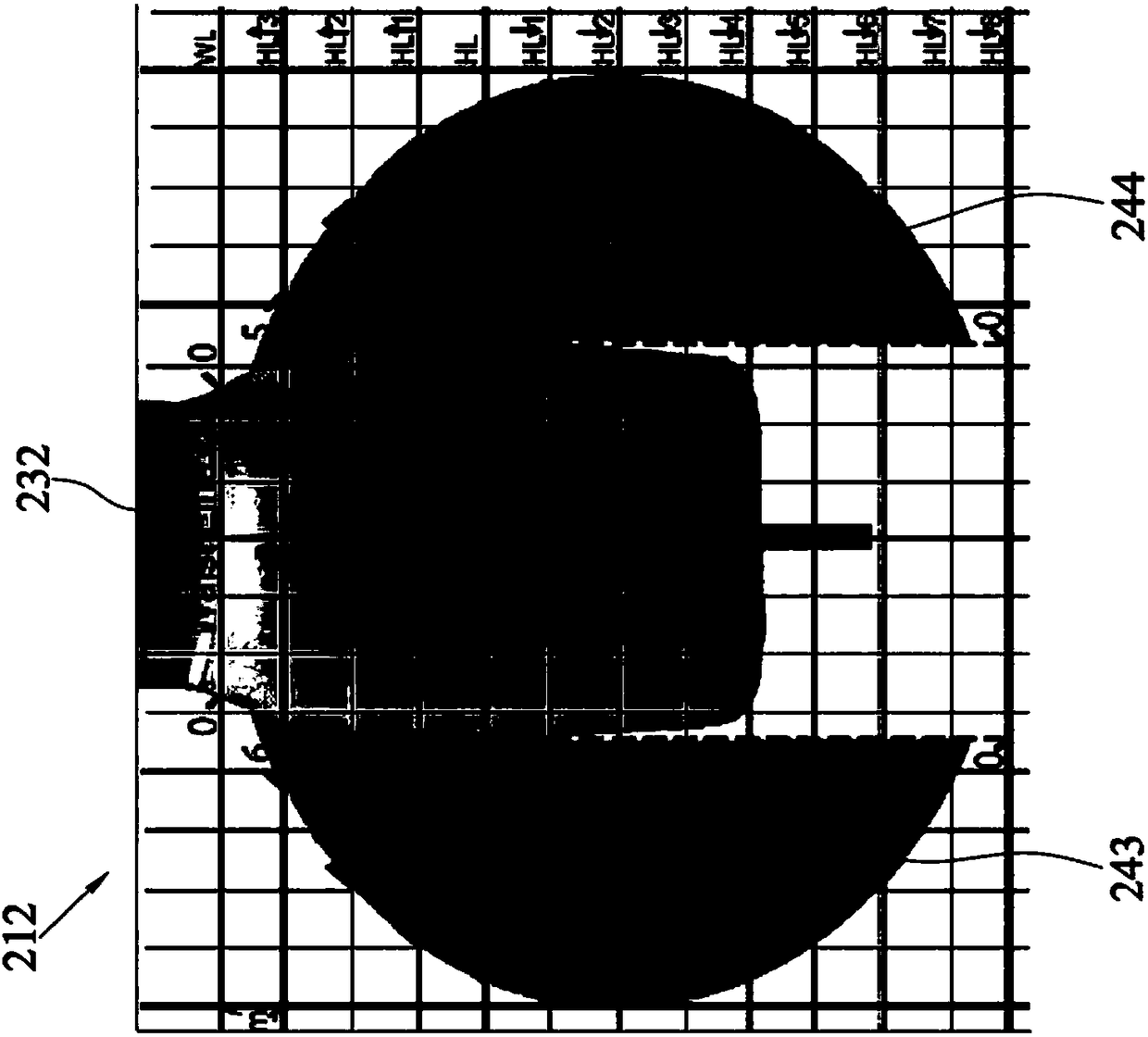

[0031] see figure 1 , to illustrate the step flow of the manufacturing method of the three-dimensional sculpture garment of the present invention. The manufacturing method of three-dimensional sculpture clothing of the present invention, in step S11, first through such as Figure 6 The interface 21 of an electronic device 2 is shown to obtain a plurality of first loose data of a clothing design drawing corresponding to a sculpture model. In one embodiment, the electronic device 2 is a mobile phone, a tablet computer, a desktop computer or a cloud server, and the interface 21 is an application displayed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com