A reaction kettle having double heat dissipation functions

A dual heat dissipation and reaction kettle technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problems of high cost and high energy consumption, and achieve Low cost, good effect and compact structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

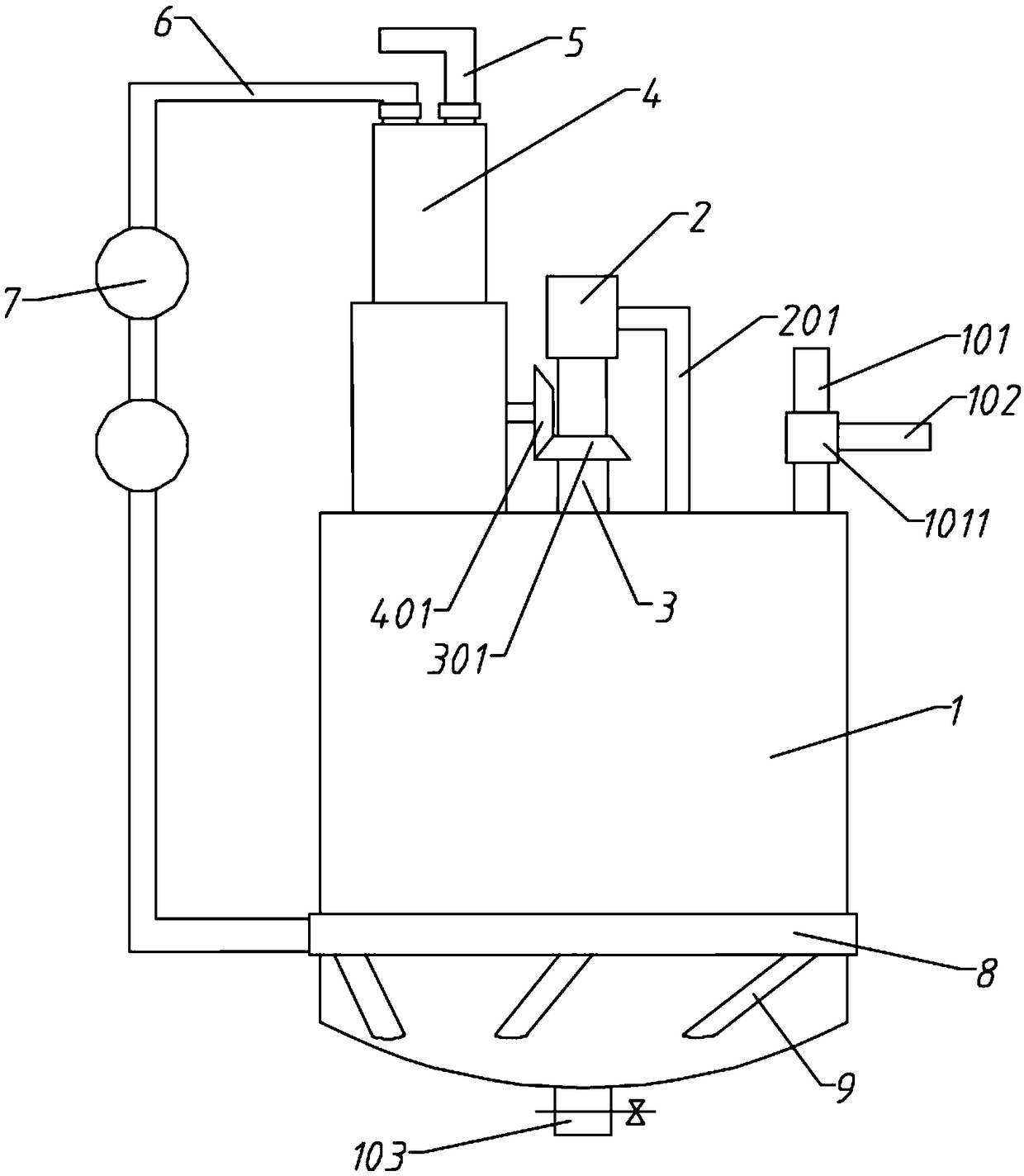

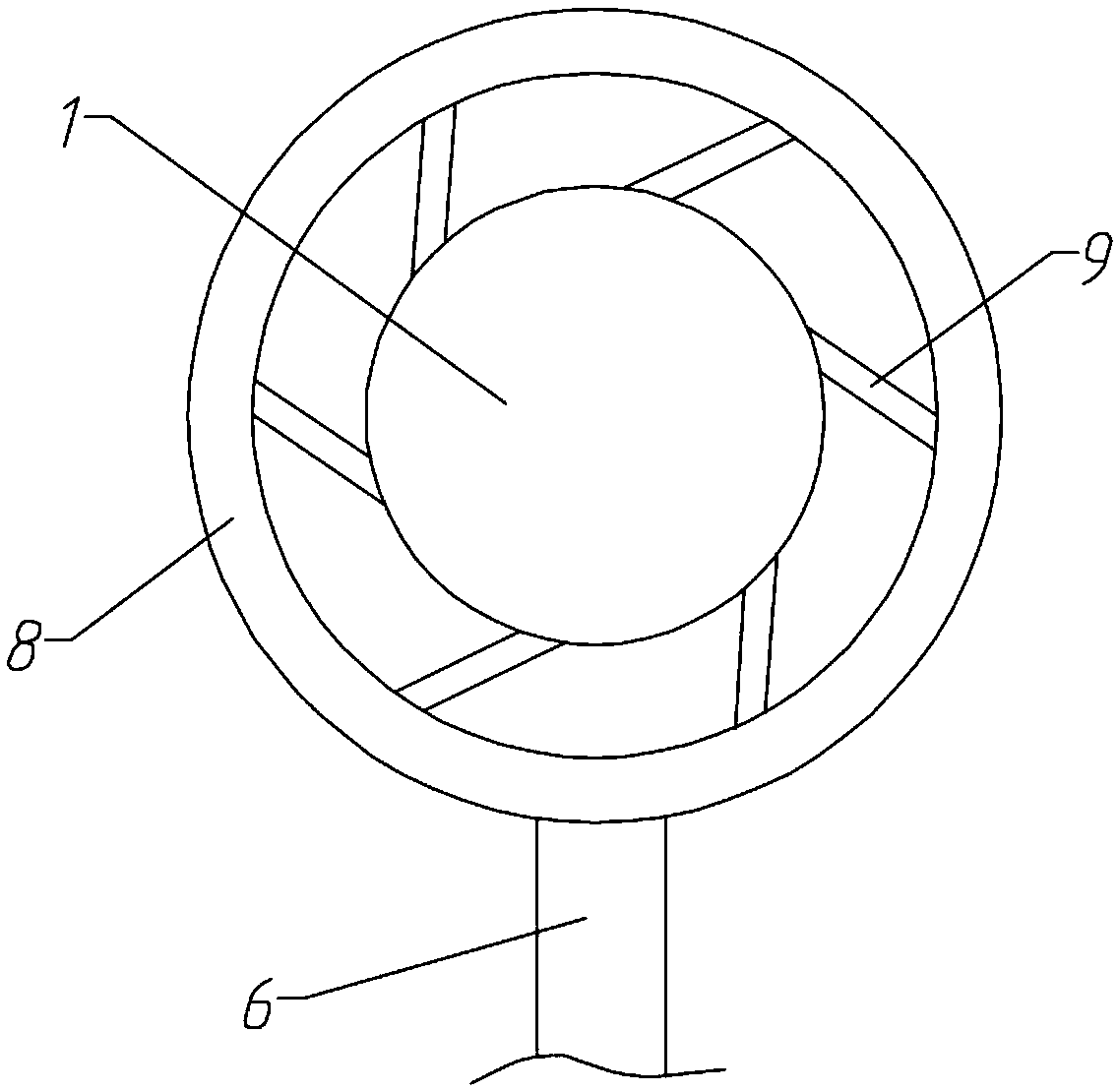

[0038] A reaction kettle with dual heat dissipation functions, including a tank body 1, a stirring component and a suction structure 4;

[0039] The top of the tank body 1 is equipped with a driving motor 2, and the driving motor 2 is connected with a driving shaft 3 downward. Components; the top end of the tank body 1 is connected with a liquid inlet pipe 101, and the liquid inlet pipe 101 is connected with an exhaust branch pipe 102 through a three-way valve 1011, so that it is convenient to switch as a feeding pipe or an exhaust pipe;

[0040] The stirring assembly includes a stirring rod 302 with one end hinged on the driving shaft 3. The stirring rod 302 is also connected to the driving shaft 3 through a spring 303. The spring 303 pulls the stirring rod 302 to form an acute angle with the vertical upward direction; specifically, the driving motor 2 drives the driving shaft 3 to rotate, and the stirring rod 302 is subjected to the centrifugal force and the pulling force of...

Embodiment 2

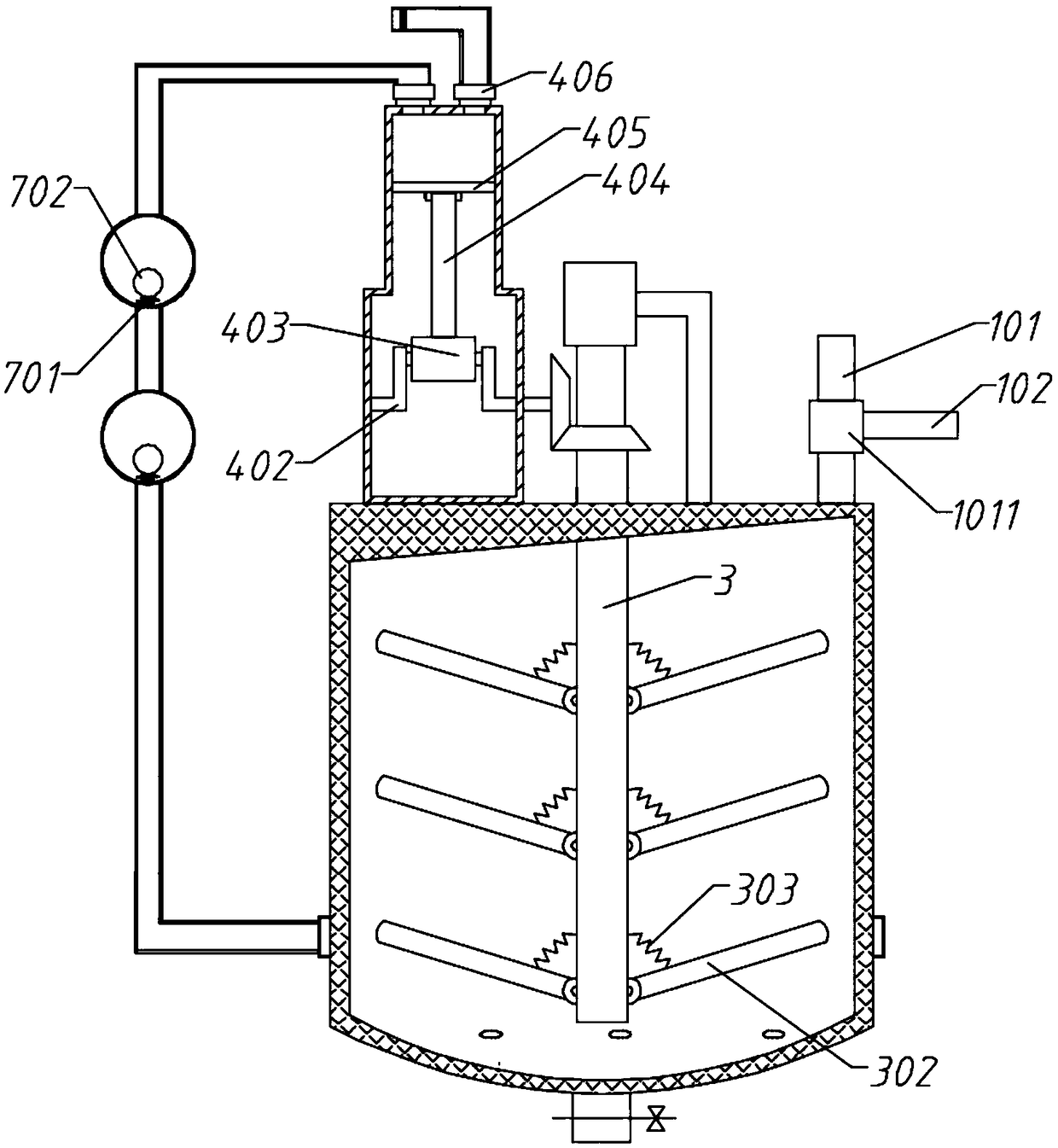

[0050] A reaction kettle with dual heat dissipation functions, including a tank body 1, a stirring component and a suction structure 4;

[0051] The top of the tank body 1 is equipped with a driving motor 2, and the driving motor 2 is connected with a driving shaft 3 downward. Components; the top end of the tank body 1 is connected with a liquid inlet pipe 101, and the liquid inlet pipe 101 is connected with an exhaust branch pipe 102 through a three-way valve 1011, so that it is convenient to switch as a feeding pipe or an exhaust pipe;

[0052] The stirring assembly includes a stirring rod 302 with one end hinged on the driving shaft 3. The stirring rod 302 is also connected to the driving shaft 3 through a spring 303. The spring 303 pulls the stirring rod 302 to form an acute angle with the vertical upward direction; specifically, the driving motor 2 drives the driving shaft 3 to rotate, and the stirring rod 302 is subjected to the centrifugal force and the pulling force of...

Embodiment 3

[0062] A reaction kettle with dual heat dissipation functions, including a tank body 1, a stirring component and a suction structure 4;

[0063] The top of the tank body 1 is equipped with a driving motor 2, and the driving motor 2 is connected with a driving shaft 3 downward. Components; the top end of the tank body 1 is connected with a liquid inlet pipe 101, and the liquid inlet pipe 101 is connected with an exhaust branch pipe 102 through a three-way valve 1011, so that it is convenient to switch as a feeding pipe or an exhaust pipe;

[0064] The stirring assembly includes a stirring rod 302 with one end hinged on the driving shaft 3. The stirring rod 302 is also connected to the driving shaft 3 through a spring 303. The spring 303 pulls the stirring rod 302 to form an acute angle with the vertical upward direction; specifically, the driving motor 2 drives the driving shaft 3 to rotate, and the stirring rod 302 is subjected to the centrifugal force and the pulling force of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com