A diamond geological core drill bit using heat pipe to dissipate heat

A coring bit and heat pipe technology, which is applied in the direction of drill bit, undisturbed core extraction device, drilling tool, etc., can solve the problems of temperature rise in the grinding part of the drill bit, wear and tear of the drill bit, occurrence and other problems, so as to reduce manufacturing cost, reduce consumption, and improve The effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to avoid obscuring the essence of the present invention, well-known methods, procedures and procedures have not been described in detail.

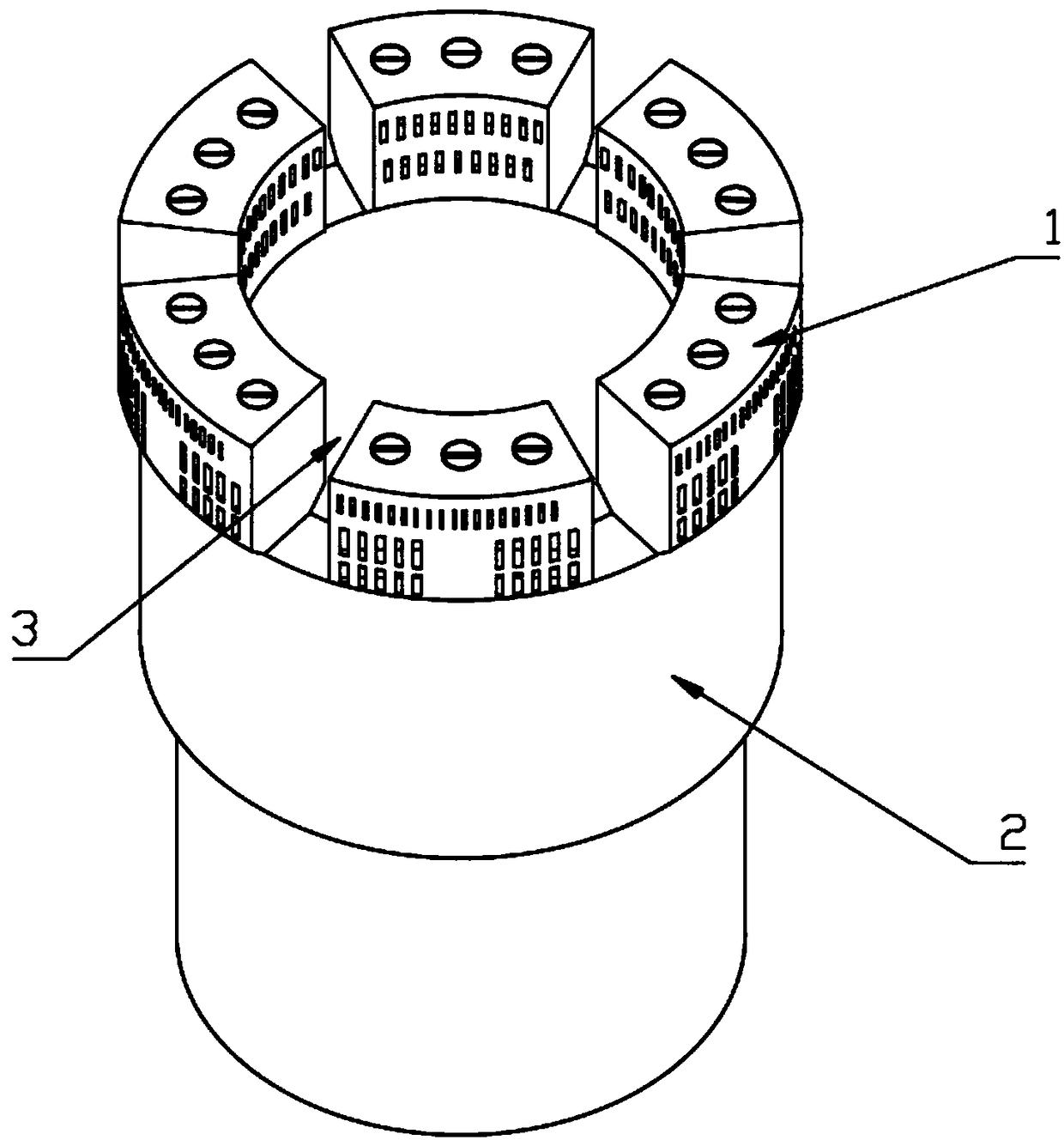

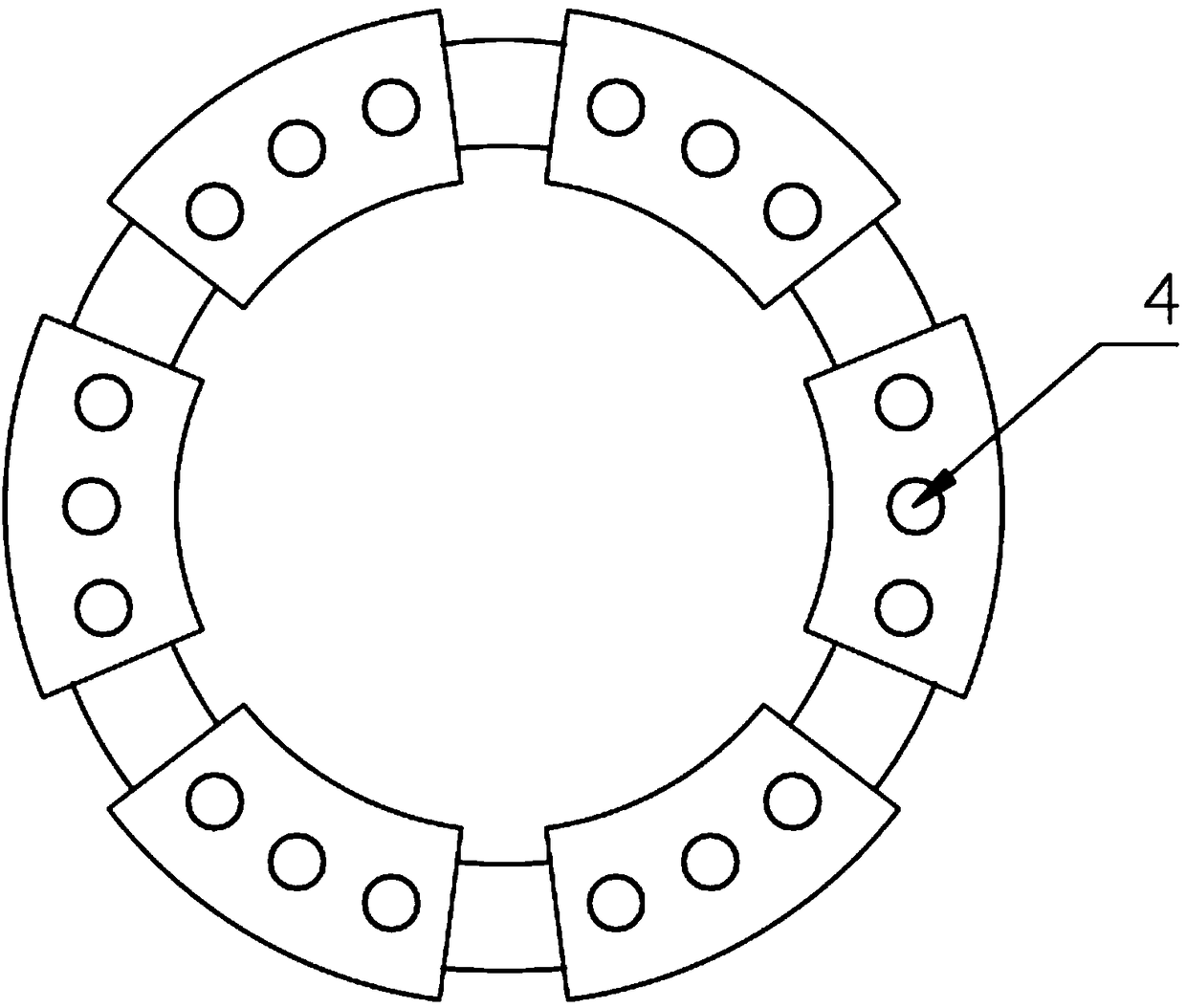

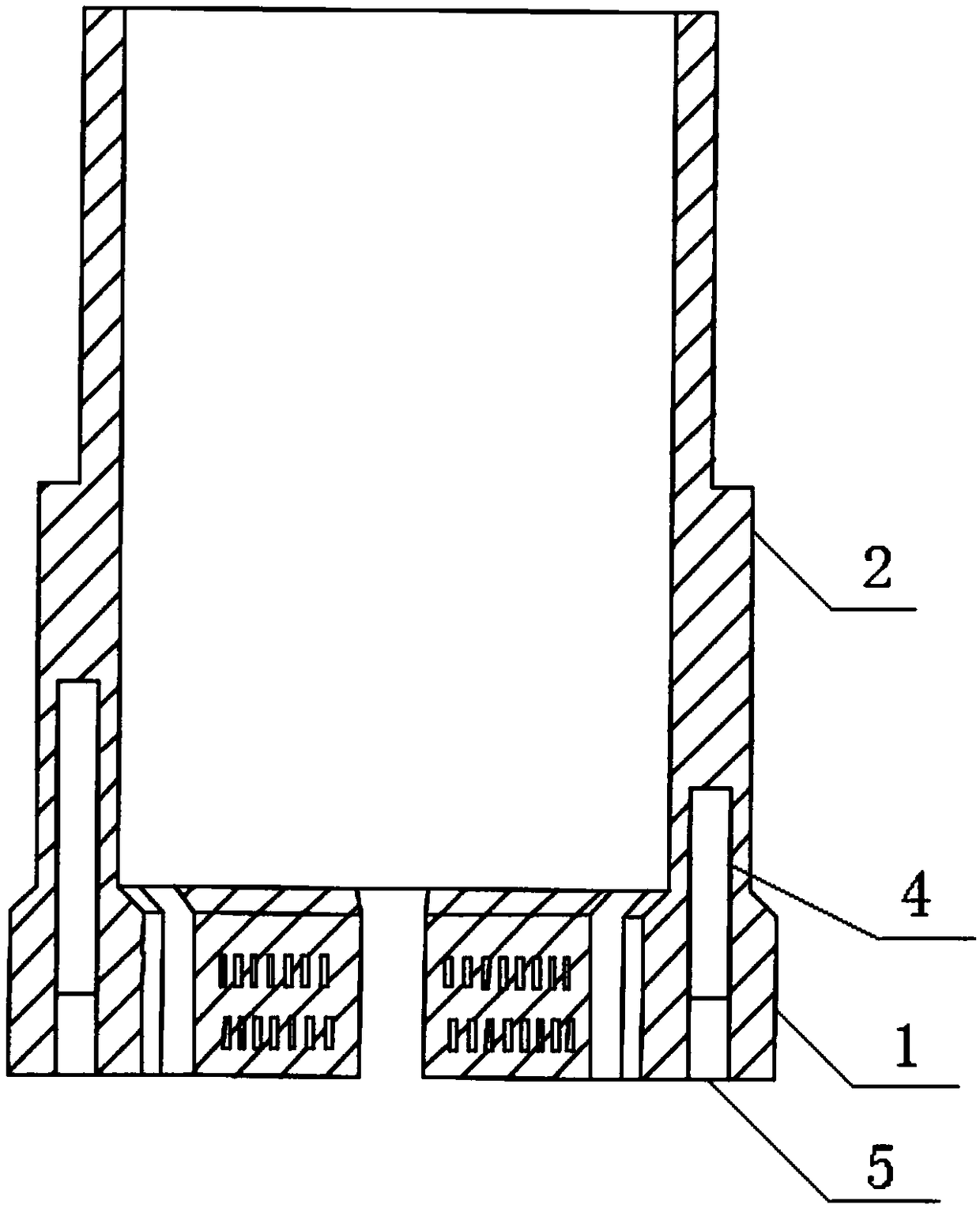

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention proposes a diamond geological core bit that utilizes heat pipes to dissipate heat, comprising a drill body 1, a steel body 2, a nozzle 3, a heat pipe 4 and a heat conduction column 5, and the drill body 1 is bonded to steel by sintering. The drill body 2 is connected, wherein the drill bit matrix 1 is composed of the matrix working layer 11 and the matrix transition layer 12, and a steel body threaded hole is opened in the axial direction on the steel body 2; the nozzle 3 is set on the drill bit matrix 1 and divide the bit matrix 1 into several blades, and on the blade corresponding to the position of the threaded hole of the steel body, a threaded hole of the body is provided along the axial direction of the blade; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com