A kind of method for treating kitchen and kitchen waste

A technology of kitchen waste and kitchen waste, which is applied in the field of kitchen waste treatment and kitchen, can solve the problems of low water content, inability to finely separate kitchen waste, and no specific method of solid-liquid separation, so as to achieve utilization The effect of high efficiency and high decomposition treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

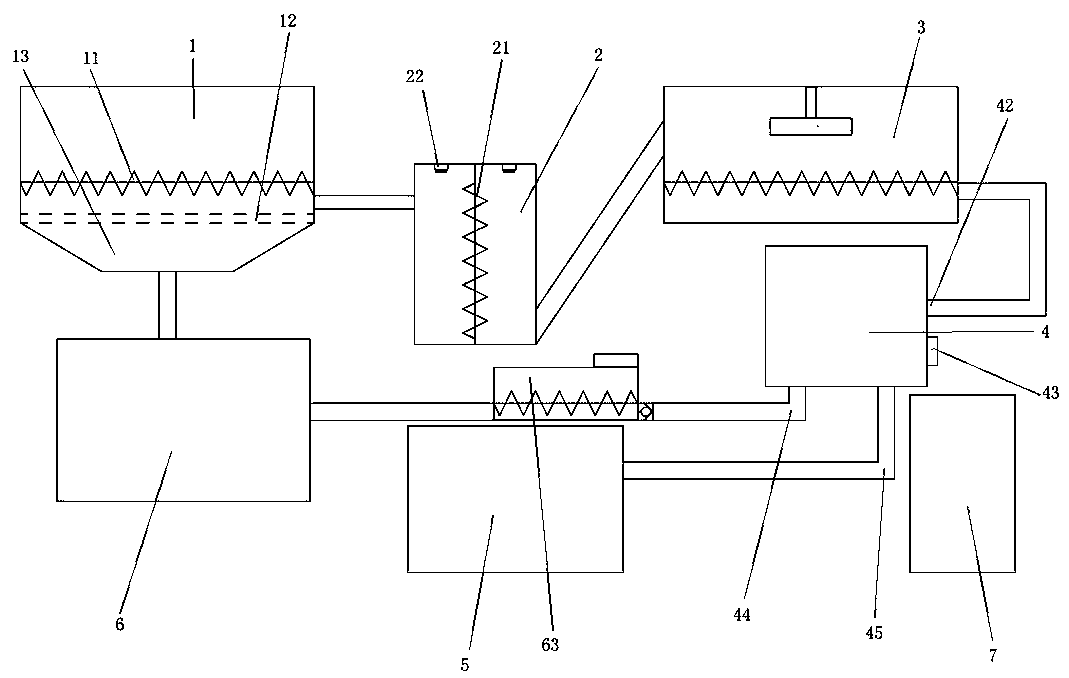

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

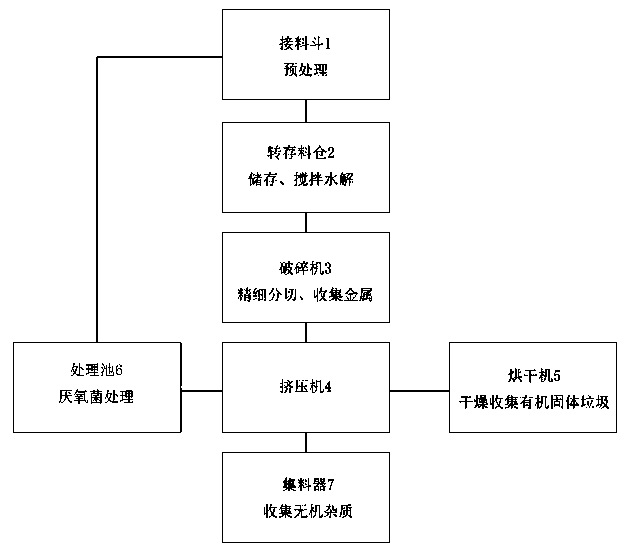

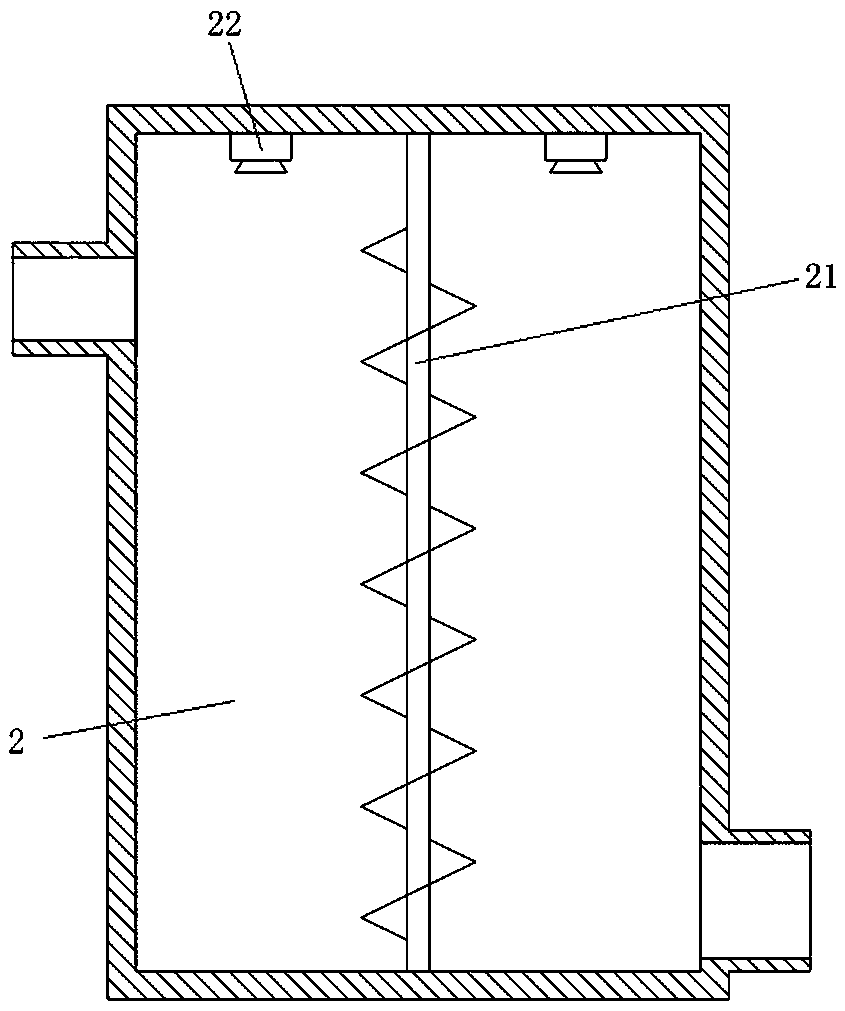

[0036] like figure 1 , 2 Shown is a method for treating kitchen and kitchen waste, which implements its steps through the following devices: including a receiving hopper 1 connected in sequence by a bolt conveyor, a transfer bin 2, a crusher 3, and an extruder 4. A dryer 5, a treatment pool 6 and a collector 7 are connected in parallel behind the extruder 4.

[0037] The method includes the following steps:

[0038] Step 1: Put the collected kitchen and kitchen waste into the receiving hopper 1 for pretreatment including bag breaking and coarse crushing. There are three horizontally juxtaposed first screws 11 inside the receiving hopper 1 , below the first screw 11 there is a liquid collection tank 13 extending downward from the receiving hopper with a sieve plate 12 , and the sieve plate 12 is along the installation direction of the first screw rod 11 It is arranged under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com