Abrasive belt grinder with wet dust removal system

A technology of wet dust removal and dust removal system, which is applied in the direction of abrasive belt grinders, grinding machines, grinding/polishing equipment, etc., which can solve the problems of operators' health impact, multi-metal waste and dust, and no dust removal equipment to reduce the impact , lower content, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

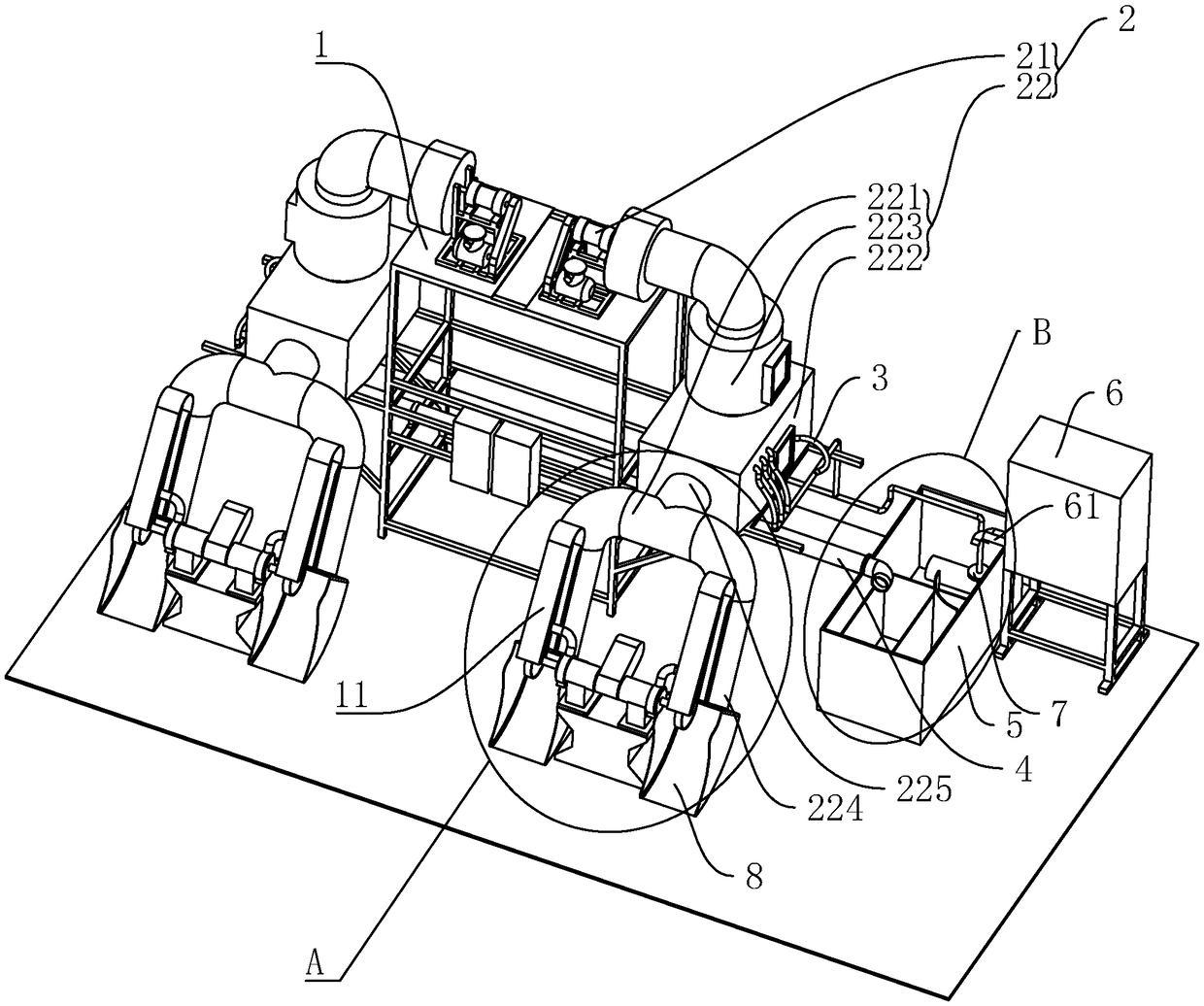

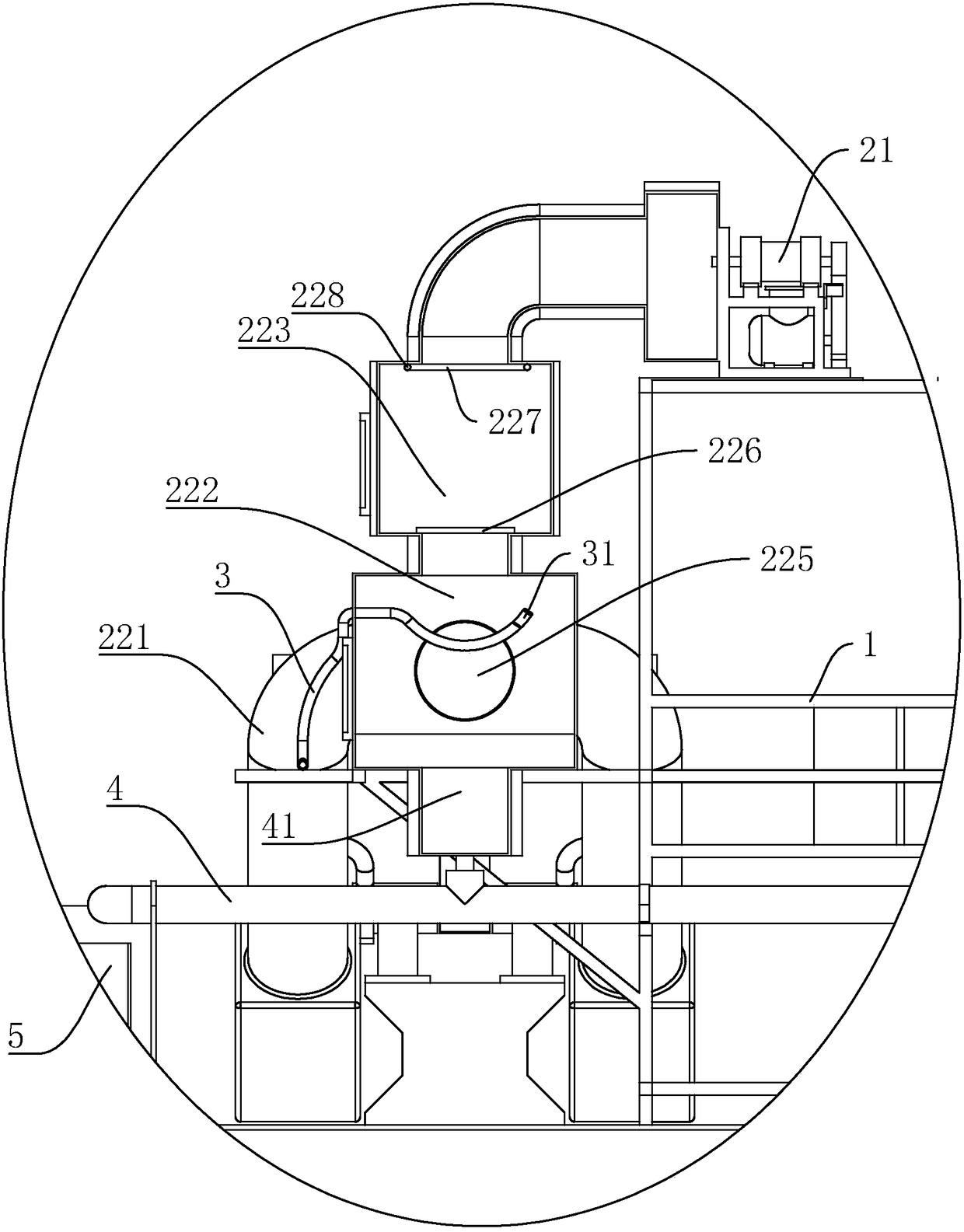

[0039] Embodiment 1: a kind of abrasive belt mill with wet dust removal system, such as figure 1 As shown, it includes a square frame 1, two symmetrically arranged grinding units 11 are fixed in front of the frame 1, a dust removal system 2 is fixed on the frame 1 behind the grinding unit 11, and a filter filter is installed on the right side of the dust removal system 2. A water storage tank 6 is fixed outside the box 5 and the filter box 5 , and a water replenishment pipe 61 is communicated with the water storage tank 6 , and the water replenishment pipe 61 extends into the filter box 5 .

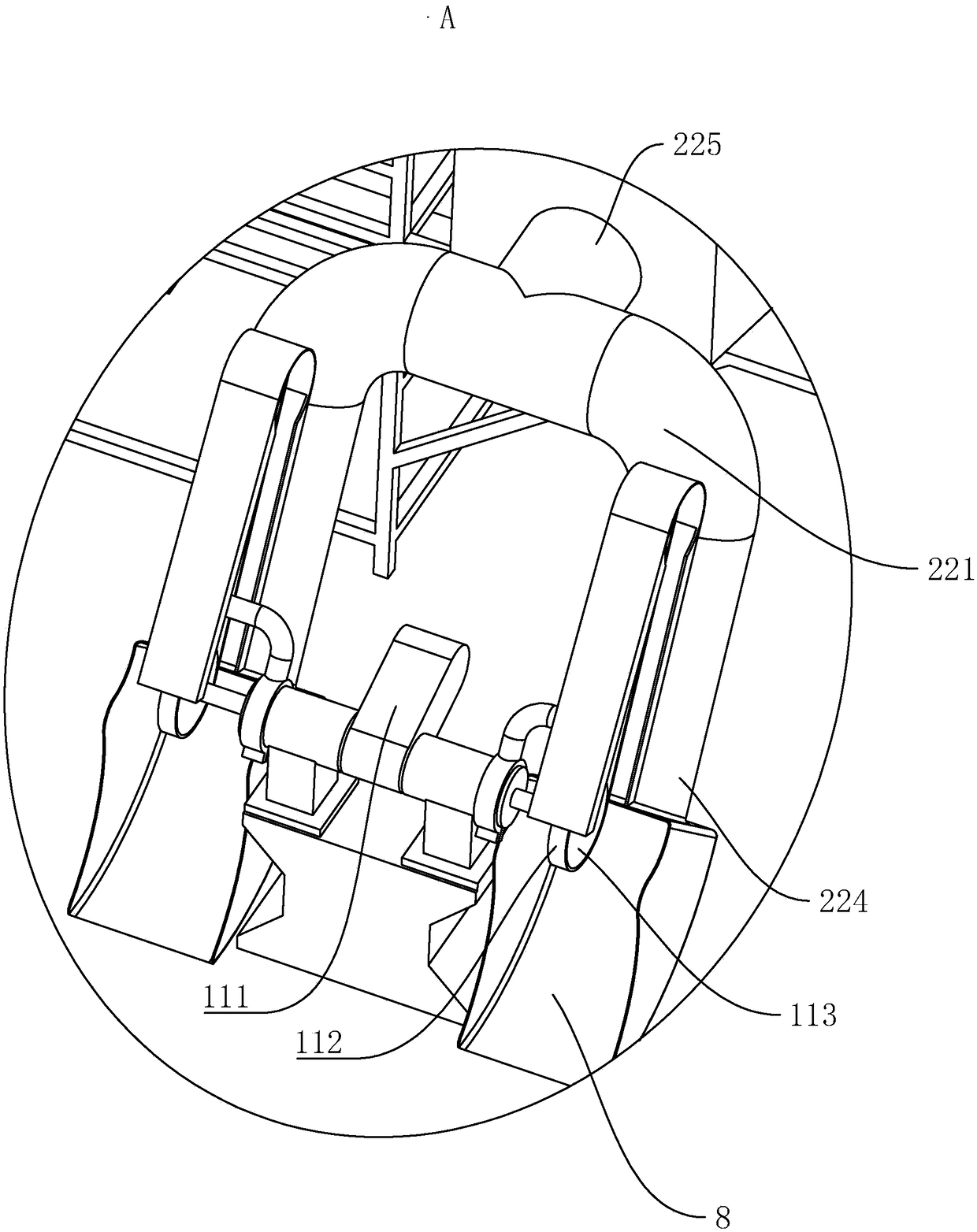

[0040] Such as figure 1 and figure 2 As shown, the grinding unit 11 includes a driving motor 111 arranged in the middle, a pulley 113 is fixed on the output shaft of the driving motor 111, and a polishing belt 112 is wound on the belt pulley 113, and the output shaft of the driving motor 111 rotates to drive the belt The wheel 113 and the grinding belt 112 rotate, and the operator can gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com