Manufacturing method of simple imitated wood trash can

A production method and technology for a trash can, which are applied in the field of trash cans, can solve problems such as unreasonable, complicated and unsatisfactory production processes, and achieve the effects of wide popularization and application prospects, simple and easy production, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The manufacture method of the simple and easy imitation wood trash can of the present invention comprises the following steps:

[0028] a. Determine the shape and size of the trash can according to the design, and weld the steel bar to make the steel main skeleton of the trash can.

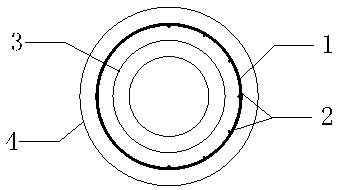

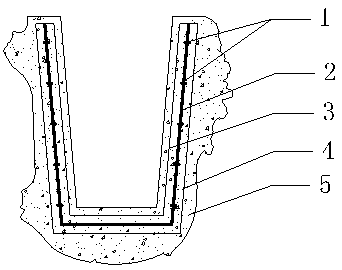

[0029] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of the metal skeleton structure of the imitation wood garbage bin of the embodiment of the present invention, figure 2 It is a sectional view of a wood-like trash can according to an embodiment of the present invention.

[0030] b. The inner and outer surfaces of the steel main frame are covered with steel wire mesh, and the inner steel wire mesh 3 and the outer steel wire mesh 4 steel mesh are bound on the steel bar main frame with binding wires, so that the steel wire mesh is equivalent to the product mold, and the main frame is covered with steel wires In the net; the main reinforcement 2 of the steel bar mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com