Landing gear cushioning mechanism and landing gear

A buffer mechanism and landing gear technology, applied in landing gear, aircraft parts, transportation and packaging, etc., can solve the problems of inaccurate wheel load signals and inability to directly install wheel load switch sensors, so as to reduce overload coefficient and ensure buffer efficiency. , the effect of high buffer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

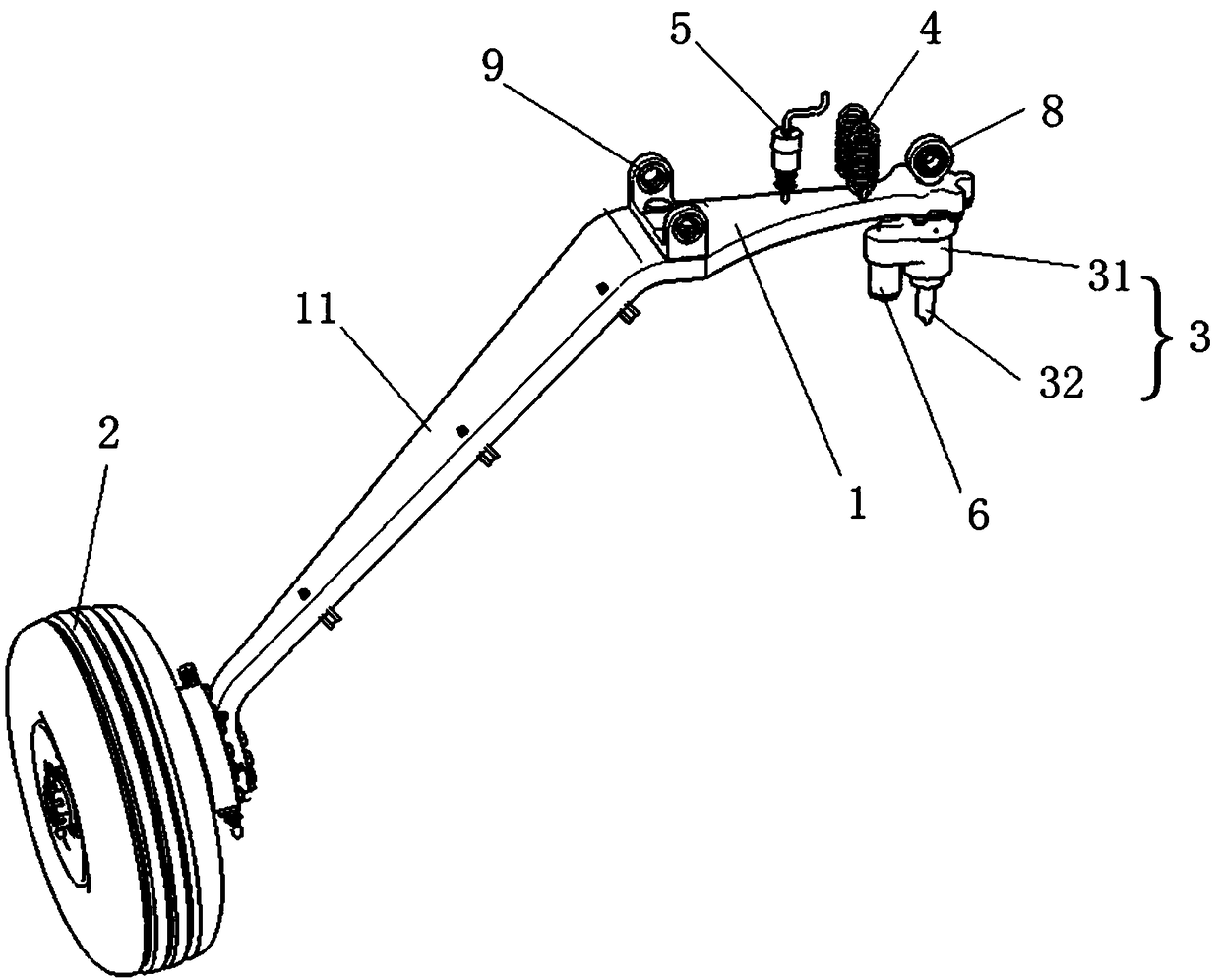

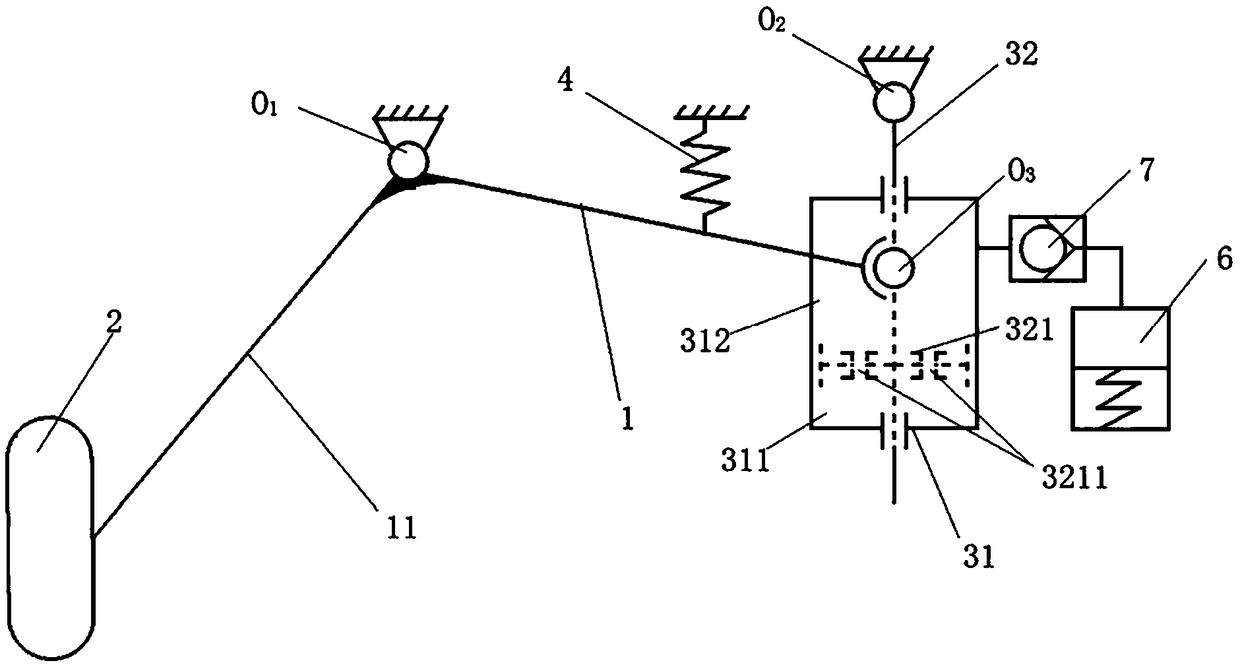

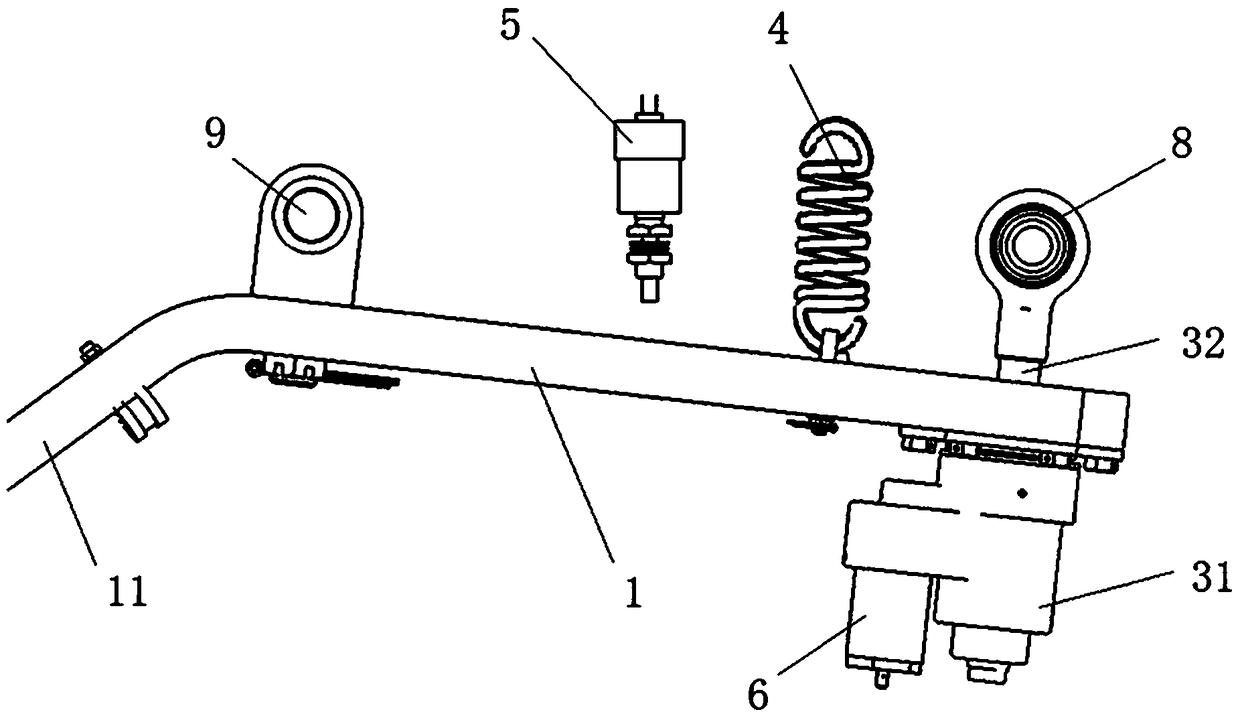

[0049] like figure 1 and figure 2 As shown, the landing gear of this embodiment has a leaf spring 1, a landing gear wheel 2, a spring 4, a wheel load switch 5, a liquid compensation cylinder 6 and a one-way valve 7.

[0050] One end of the leaf spring 1 is bent downward to form a folding arm 11 connecting the landing gear wheel 2, and the middle part of the leaf spring 1 is fixed with a connecting seat 9, and the leaf spring 1 is connected to the fuselage of the aircraft at the first hinge point O through the connecting seat 9. 1 hinged. The other end of leaf spring 1 is provided with buffer 3, and buffer 3 comprises outer cylinder 31 and piston rod 32, and outer cylinder 31 is located at the lower end of leaf spring 1 and is at the third hinge point O with leaf spring 1. 3 hinged. Piston rod 32 has one end of piston 321 and stretches in the outer cylinder 31 after passing leaf spring 1, and piston rod 32 runs through outer cylinder 31 and is connected with outer cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com