Swinging rotating drawstring cutting device for automatic buckle threading machine

A cutting device and automatic threading technology, applied in fasteners, buckles, applications, etc., can solve the problems of high labor intensity, difficulty in unifying buckle specifications, and poor product consistency, so as to reduce labor intensity of workers and facilitate follow-up operations , the effect of uniform buckle specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

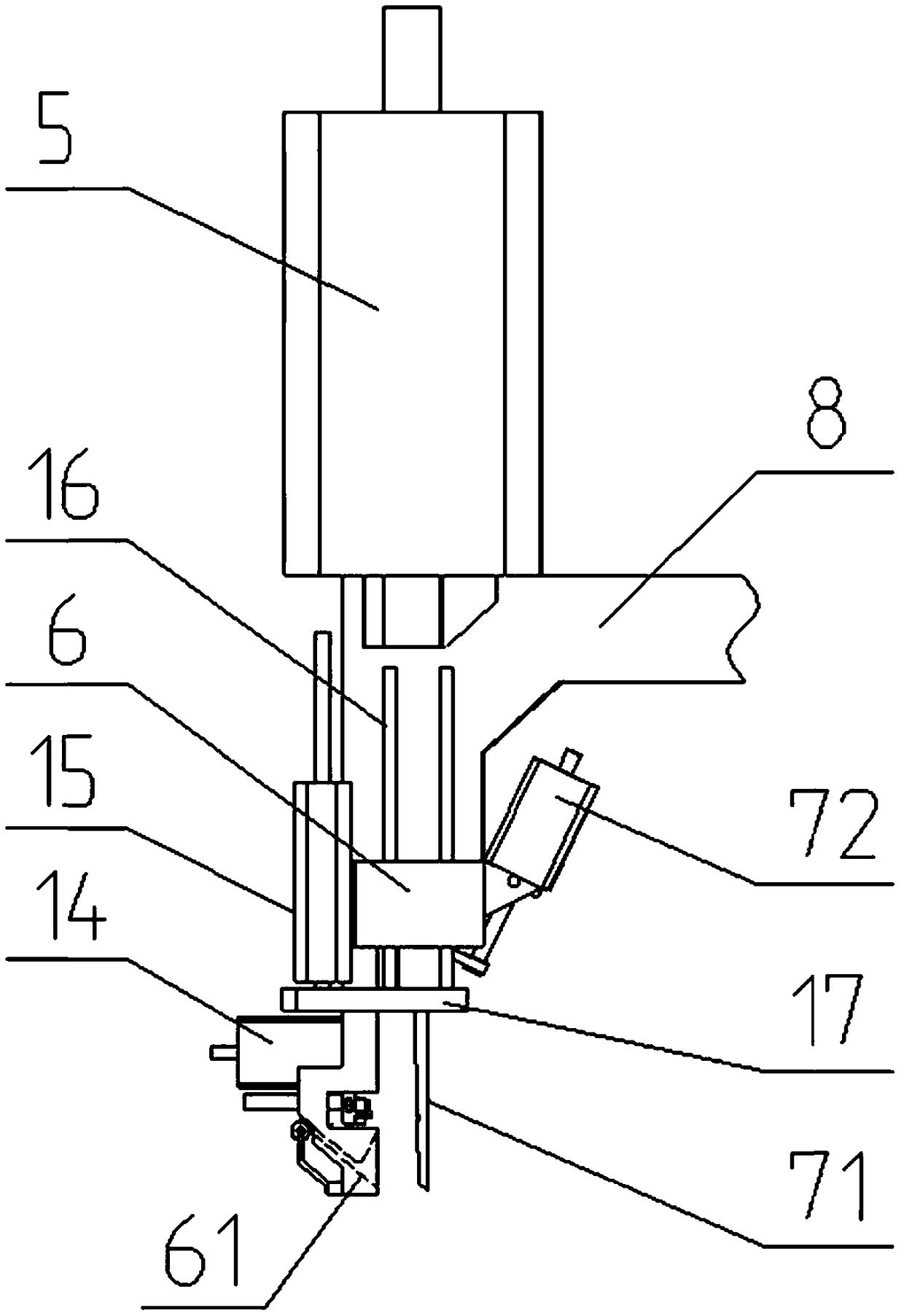

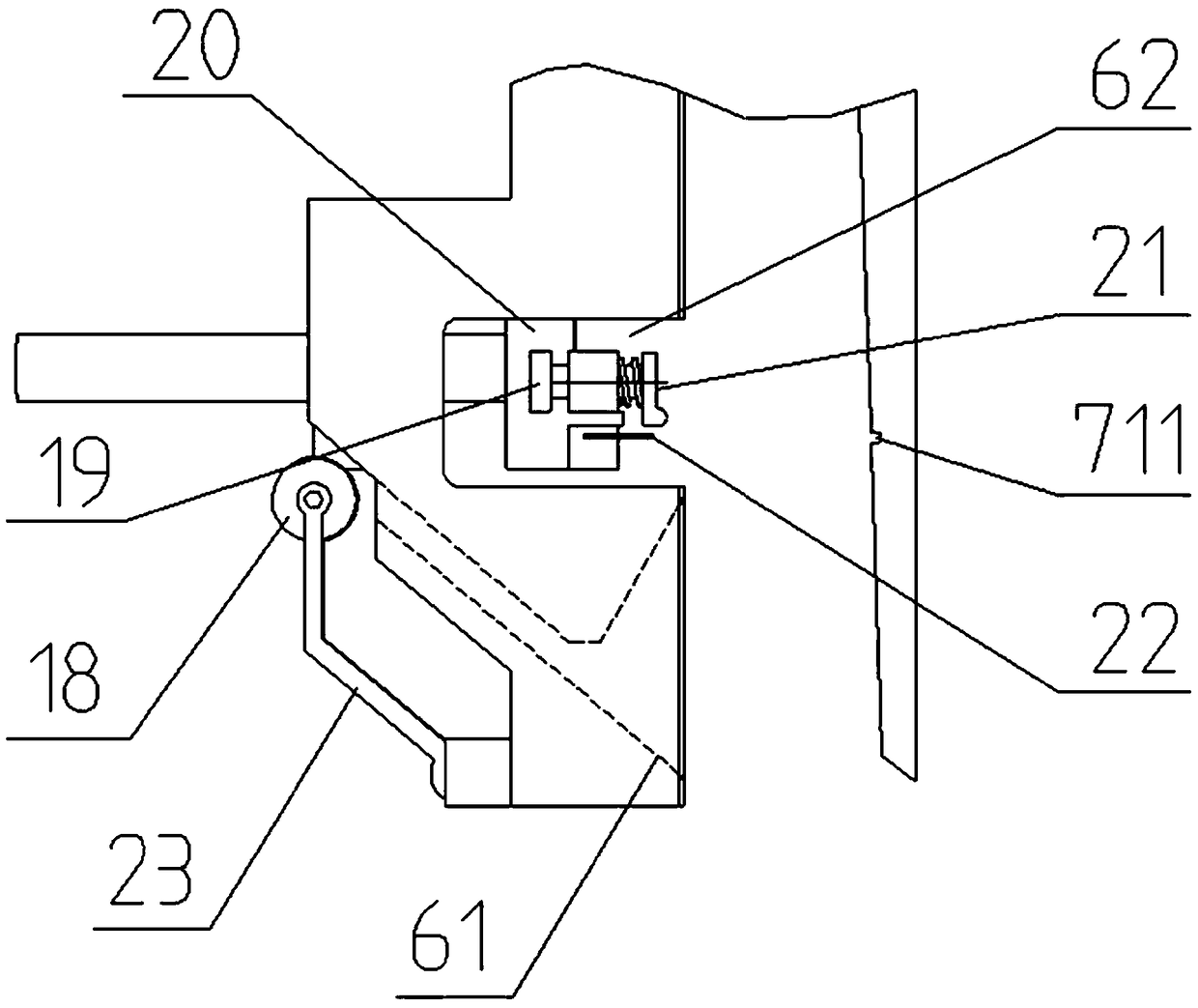

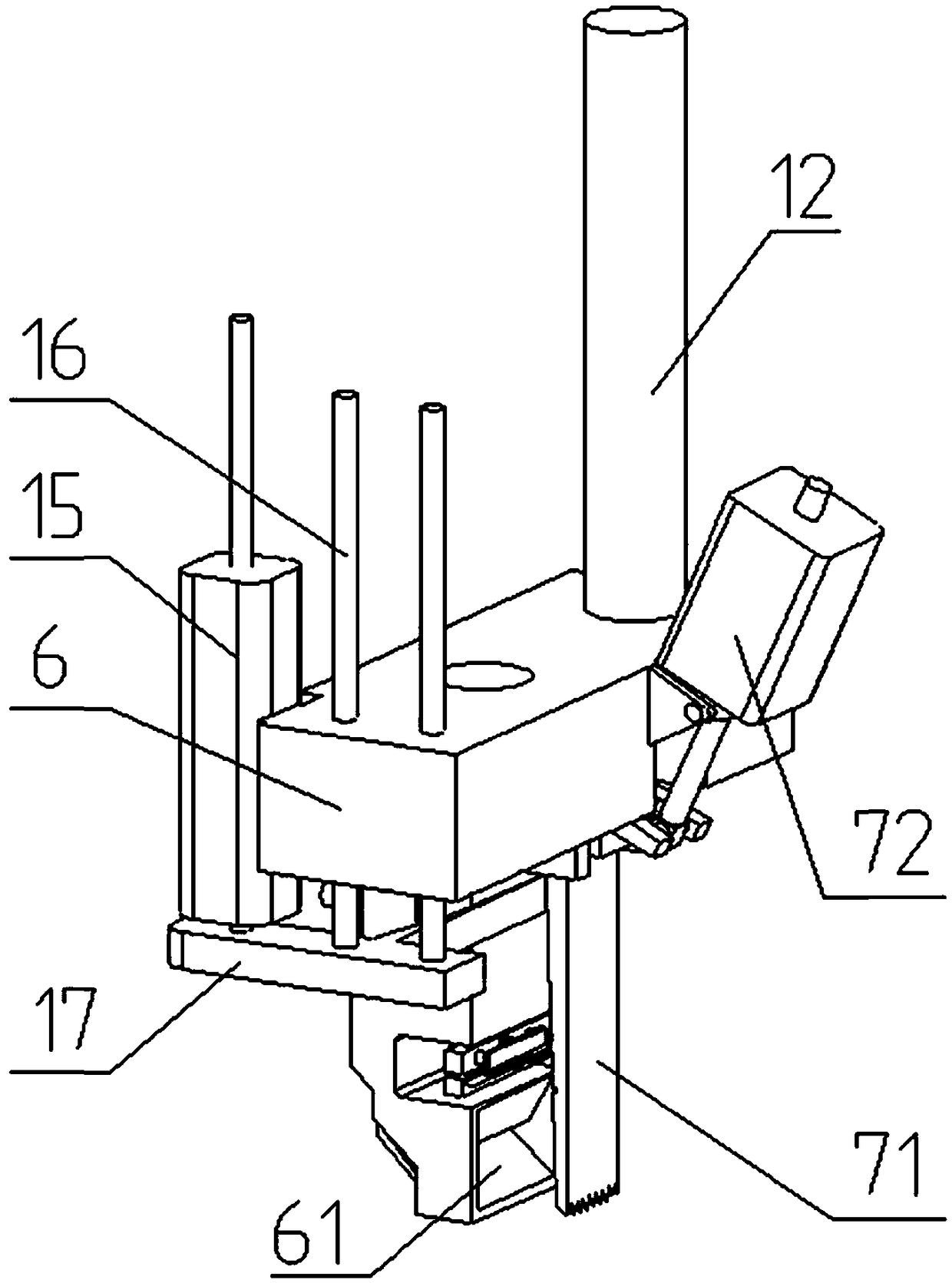

[0029] Such as Figure 1-Figure 5 As shown, the present invention relates to a swinging drawstring cutting device applicable to an automatic button threading machine, comprising a sliding support 8, on the cantilever end of the sliding support 8, there are respectively interconnected driving devices and The fifth wheel 6, the driving device is used to drive the fifth wheel 6 to move up and down. A vertically arranged guide post 12 is installed on the traction seat 6 and runs through the sliding support 8 through the guide post 12. It runs through the sliding support 8 and is threadedly connected with the traction seat 6, and is used to drive the traction seat 6 to move up and down, thereby passing the tensioned cloth belt into the buckle.

[0030] The lower end of the traction seat 6 is provided with a tape perforation 61 arranged obliquely. The entrance of the tape perforation 61 is a rectangular flat mouth, and its exit is inclined downwards from the entrance, and the exit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com