Carbon fiber/nanofiber synergistic tough ceramic matrix composite material and preparation method thereof

A technology of nanofibers and composite materials, which is applied in the field of carbon fiber/nanofiber synergistic tough ceramic matrix composites and its preparation, can solve the problem of difficult control of the content and distribution of carbon nanotubes, and limited long diameters of nanowires and whiskers. Ratio, large-scale production does not have advantages, etc., to achieve the effect of low cost, controllable distribution, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

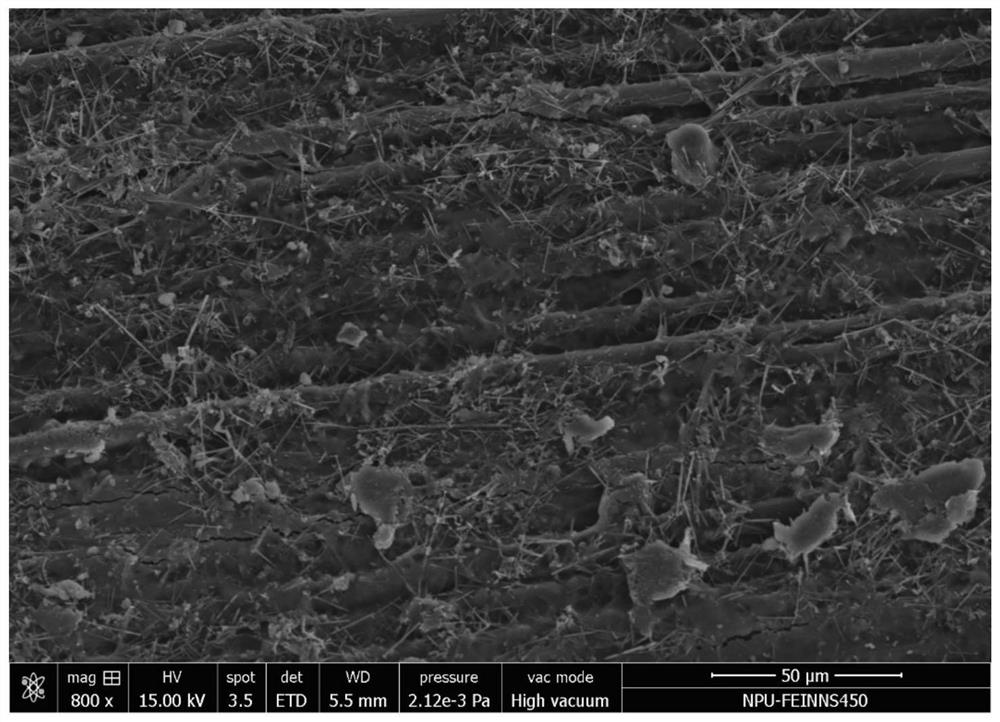

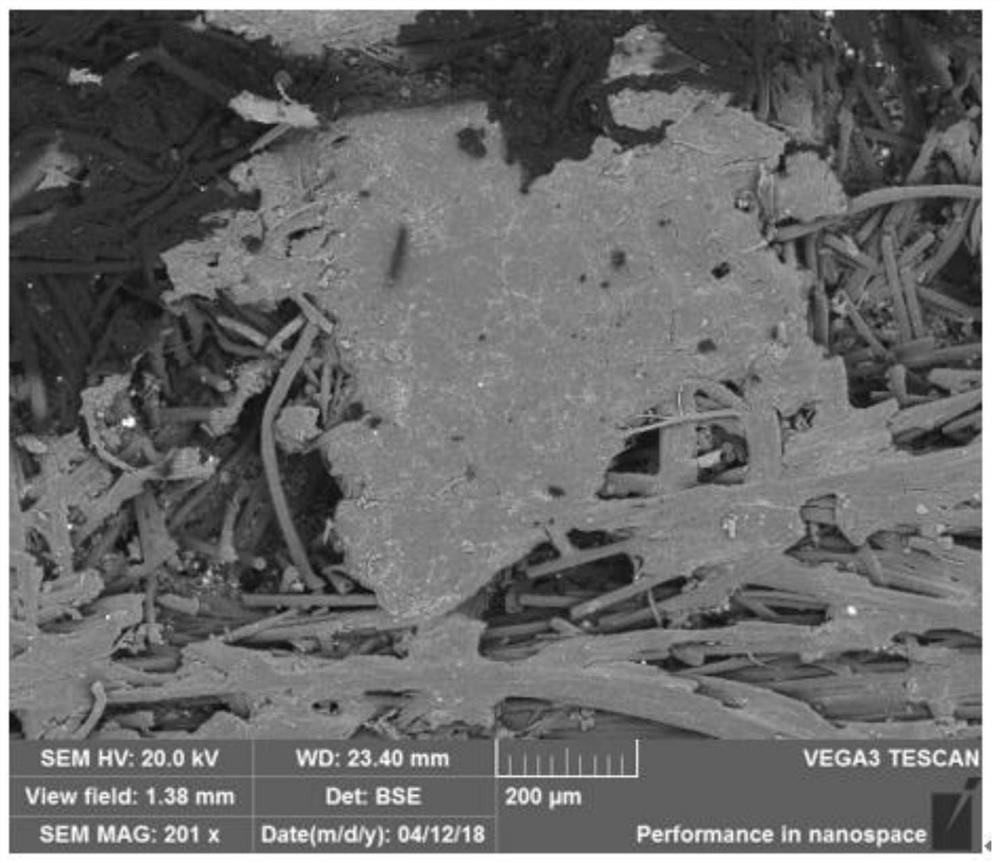

[0038] A method for preparing a carbon fiber / nano fiber synergistic tough ceramic matrix composite material, comprising the following steps:

[0039] (1) Pre-treatment of carbon fiber sizing: the pre-treatment working solution is a mixed solution of ethanol and water, the concentration of the mixed solution is 65%, the pre-treatment working solution is placed in the slurry tank, and the temperature of the slurry tank is room temperature 25 ° C. The sizing machine is dried by a bellows at a drying temperature of 65°C and wound at a speed of 10m / min to obtain flattened carbon fiber bundles;

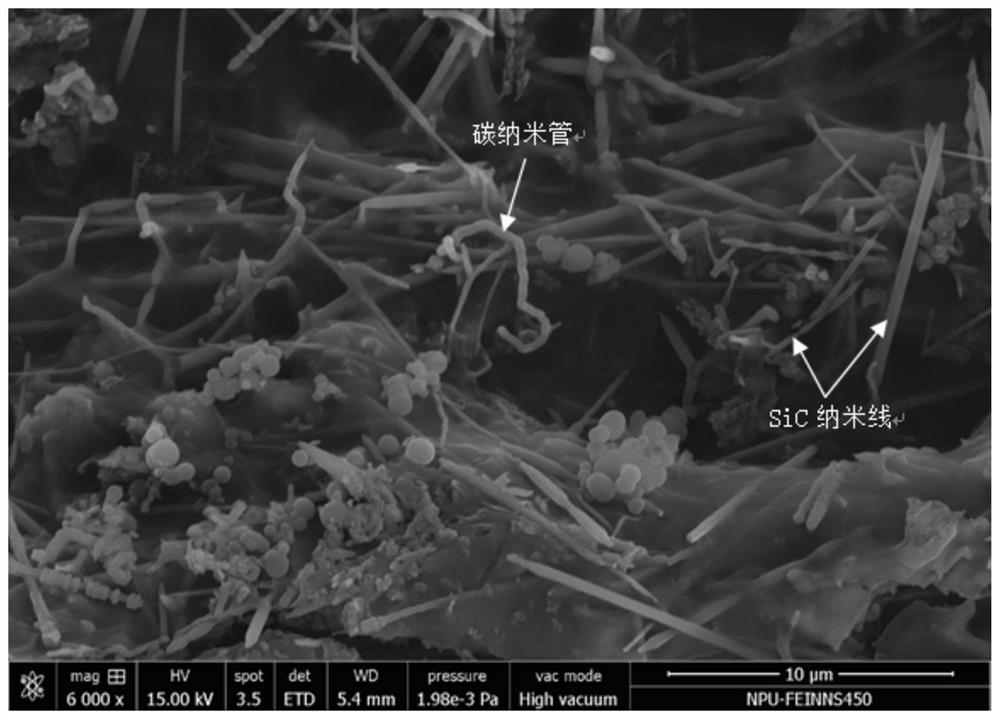

[0040] (2) Slurry preparation: Add nanofibers, isopropanol, oxidized starch, polyvinyl alcohol, and grease to distilled water respectively, and the solid mass ratio of isopropanol to nanofibers is 20:3, and the nanofibers include carbon nanotubes , SiC nanowires, the percentage by weight of each component of the slurry: carbon nanotubes 0.5wt.%, SiC nanowires 1wt.%, polyvinyl alcohol 2wt.%,...

Embodiment 2

[0048] A method for preparing a carbon fiber / nano fiber synergistic tough ceramic matrix composite material, comprising the following steps:

[0049] (1) Pre-treatment of carbon fiber sizing: the pre-treatment working liquid is a mixed solution of ethanol and water, the concentration of the mixed solution is 50%, the pre-treatment working liquid is placed in the slurry tank, and the temperature of the slurry tank is 45 ° C. The yarn machine is dried by a bellows at a drying temperature of 65°C and wound at a speed of 40m / min to obtain flattened carbon fiber bundles;

[0050] (2) Slurry preparation: Add nanofibers, isopropanol, oxidized starch, polyvinyl alcohol, and grease to distilled water respectively, and the nanofibers include carbon nanotubes and SiC nanowires. Tube 2wt.%, SiC nanowire 0.1wt.%, polyvinyl alcohol 3wt.%, oxidized starch 0.1wt.%, distilled water 90wt.%, grease 0.1wt.%, isopropanol 4.7wt.%, mixing and ultrasonic dispersion uniform , to prepare a slurry;

...

Embodiment 3

[0058] A method for preparing a carbon fiber / nano fiber synergistic tough ceramic matrix composite material, comprising the following steps:

[0059] (1) Pre-treatment of carbon fiber sizing: the pre-treatment working liquid is a mixed solution of ethanol and water, the concentration of the mixed solution is 10%, the pre-treatment working liquid is placed in the slurry tank, and the temperature of the slurry tank is 80 ° C. The yarn frame is dried by a bellows at a drying temperature of 80°C and wound at a speed of 100m / min to obtain flattened carbon fiber bundles;

[0060] (2) Slurry preparation: Add nanofibers, isopropanol, oxidized starch, polyvinyl alcohol, and oil respectively in distilled water, the nanofibers are carbon nanotubes, and the weight percentage of each component of the slurry: carbon nanotubes 0.2wt. %, SiC nanowire 0.8wt.%, polyvinyl alcohol 2.3wt.%, oxidized starch 1.5wt.%, distilled water 90wt.%, oil 0.2wt.%, isopropanol 5wt.%, mixed ultrasonically disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com