Fabric finishing process

A finishing and fabric technology, applied in fiber treatment, improved handle fibers, textiles and papermaking, etc., can solve the problems of fabric luster darkening, affecting fabric feel and clothing performance, easy to fall off, etc., to improve gloss strength and elasticity Good performance and comfortable feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

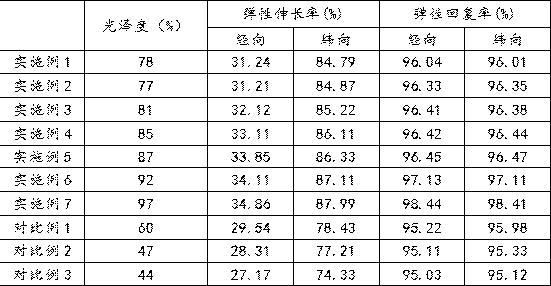

Examples

Embodiment 1

[0023] Embodiment 1: a finishing process for fabrics, comprising the following steps, step (1), singeing, singeing the fabrics with a singeing machine; step (2) boiling, placing water in the wooling tank, and heating the water To 90°C, boil it; step (3), wash it, wash it for 1 hour, clean up impurities and dirt, and rinse it; step (4), dry it, use steam to heat and dry the fabric washed in step (3) Drying; step (5), heat setting, the temperature is 190°C, time is 30s; step (6), pot steaming, steam pressure is 100kPa, time is 3min. Step (7), finishing, padding and finishing the fabric with a finishing agent, the temperature of the finishing agent is controlled at 70-85°C, and the scrapping rate is 70%. The raw materials of the finishing agent include nano-amino silicone oil and acetyl hydroxyproline. In terms of mass ratio, nanometer amino silicone oil: acetyl hydroxyproline = 100:5. The preparation method of the finishing agent is as follows. After mixing nano-amino silicone ...

Embodiment 2

[0024] Example 2: A fabric finishing process, the difference from Example 1 is that step (5), heat setting, the temperature is 180°C, and the time is 25s; step (6), pot steaming, the steam pressure is 100kPa, The time is 3 minutes; step (7), finishing, padding and finishing the fabric with a finishing agent, the temperature of the finishing agent is 85°C, and the excess rate is 85%; the preparation method of the finishing agent is as follows, taking nano-amino silicone oil and acetyl hydroxyproline After mixing, stir evenly, and use ultrasonic treatment for 25min. Step (8), drying, drying the fabric obtained in step (7) at a temperature of 70° C. for 60 minutes to obtain the fabric.

Embodiment 3

[0025] Embodiment 3: A fabric finishing process, the difference from Embodiment 1 is that step (5), heat setting, the temperature is 170° C., and the time is 25 s. The raw materials of the finishing agent include nano-amino silicone oil, acetyl hydroxyproline, and hyaluronic acid. In terms of mass ratio, nano-amino silicone oil: acetyl hydroxyproline: hyaluronic acid=100:5:8. The preparation method of the finishing agent is as follows. After mixing the components of the finishing agent raw materials, they are evenly stirred and ultrasonically treated for 20 minutes to obtain the finishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com