A control method for an air conditioning system

A control method and technology for an air-conditioning system, which are applied in the direction of noise suppression, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve problems such as throttling noise of electronic expansion valves, and achieve elimination of throttling noise and liquid flow. Effects of sound production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

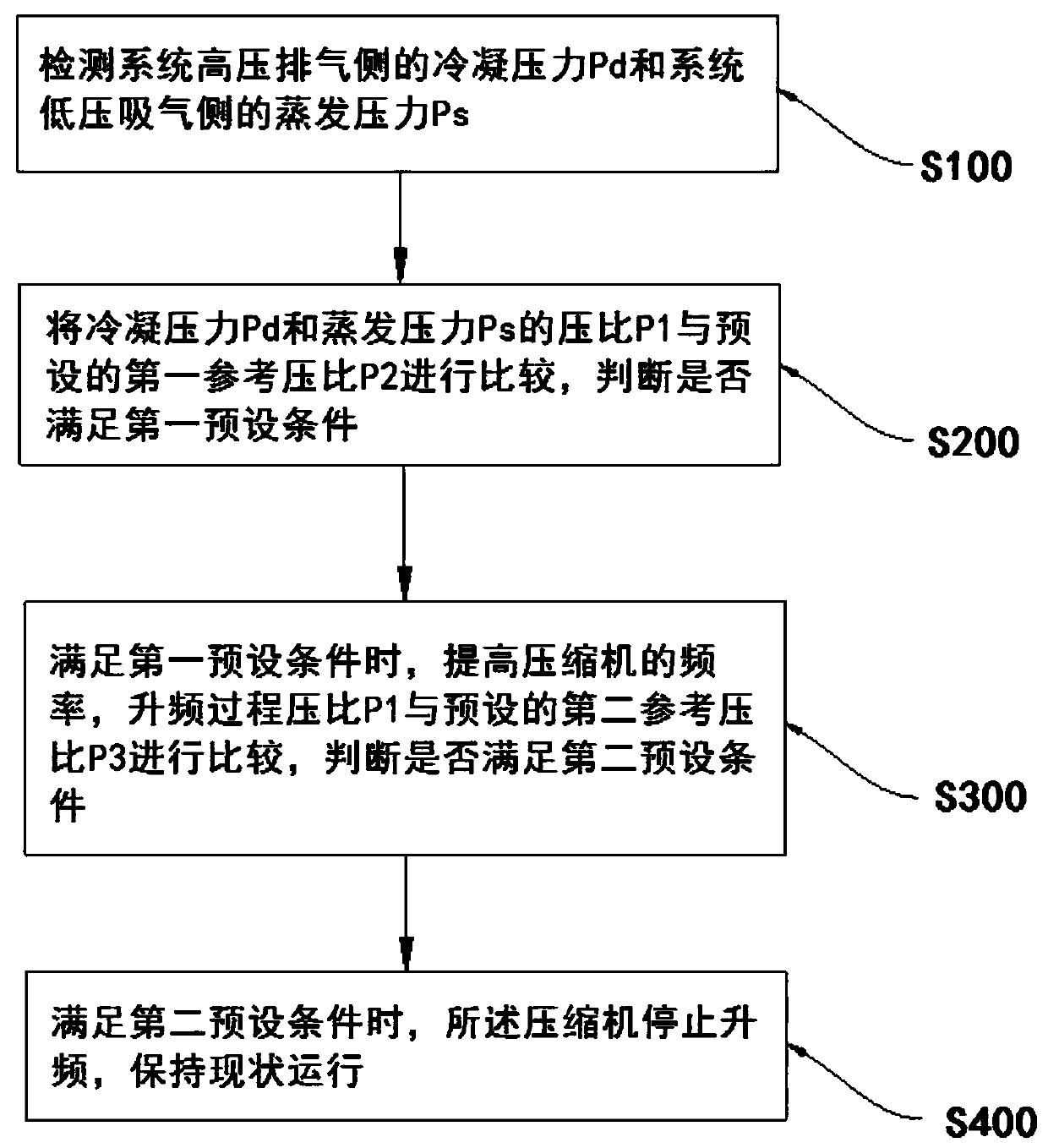

[0030] The invention provides a control method for an air conditioning system, which combines figure 1 As shown, wherein the control method of the air-conditioning system is realized based on an inverter air-conditioning system, the inverter air-conditioning system is designed with a low-pressure pressure sensor on its return air low-pressure pipeline, which is used to detect the real-time low-pressure pressure value of the system, that is, the condensation pressure Pd; A high-pressure pressure sensor is designed on the exhaust high-pressure pipeline to detect the real-time high-pressure pressure value of the system, that is, the evaporation pressure Ps; a temperature-sensing package is installed on the inner plate to detect the temperature Tem of the inner plate on the inner plate.

[0031] The frequency conversion air conditioning system includes a compressor, and a temperature sensing package is designed on the discharge port of the compressor to detect the discharge tempera...

Embodiment 2

[0048] The difference between the control method of the air-conditioning system as described in the first embodiment above is that the step S300 includes specific steps:

[0049] S310. When the first preset condition is met, monitor system parameters to determine whether there is a protection limit;

[0050] S320. When the system parameters have no protection limit, the frequency of the compressor is increased according to the fixed frequency;

[0051] S330. Detecting the condensing pressure Pd and the evaporating pressure Ps during the frequency up process, comparing the pressure ratio P1 with a preset second reference pressure ratio P3, and judging whether a second preset condition is met.

[0052]Wherein, in step S310, the monitored system parameters include the discharge temperature Td of the compressor, the temperature Tem of the inner disk, and the frequency value H of the current operation of the electronic expansion valve;

[0053] In the controller, the first referen...

Embodiment 3

[0056] As the control method of the air conditioning system described in the second embodiment above, the difference of this embodiment is that the first reference temperature T1 is 90°C, and the second reference temperature T2 is 48°C; the maximum allowable frequency value Hd of the system is 90Hz; When Tem<48°C, Td<90°C, and Ph<90Hz, it meets the requirement of frequency increase of the compressor and ensures that there are no protection limits for various parameters inside the system. The compressor can increase the flow rate of refrigerant through frequency increase, thereby increasing the electronic expansion valve. The pressure ratio of the high and low pressure sides eliminates throttling noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com