Pressure test and sorting device for rectifier bridge

A technology for withstand voltage testing and sorting devices, applied in the direction of testing dielectric strength, etc., can solve problems such as troublesome operation, low reliability, time-consuming and labor-intensive, and achieve the effect of saving costs and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

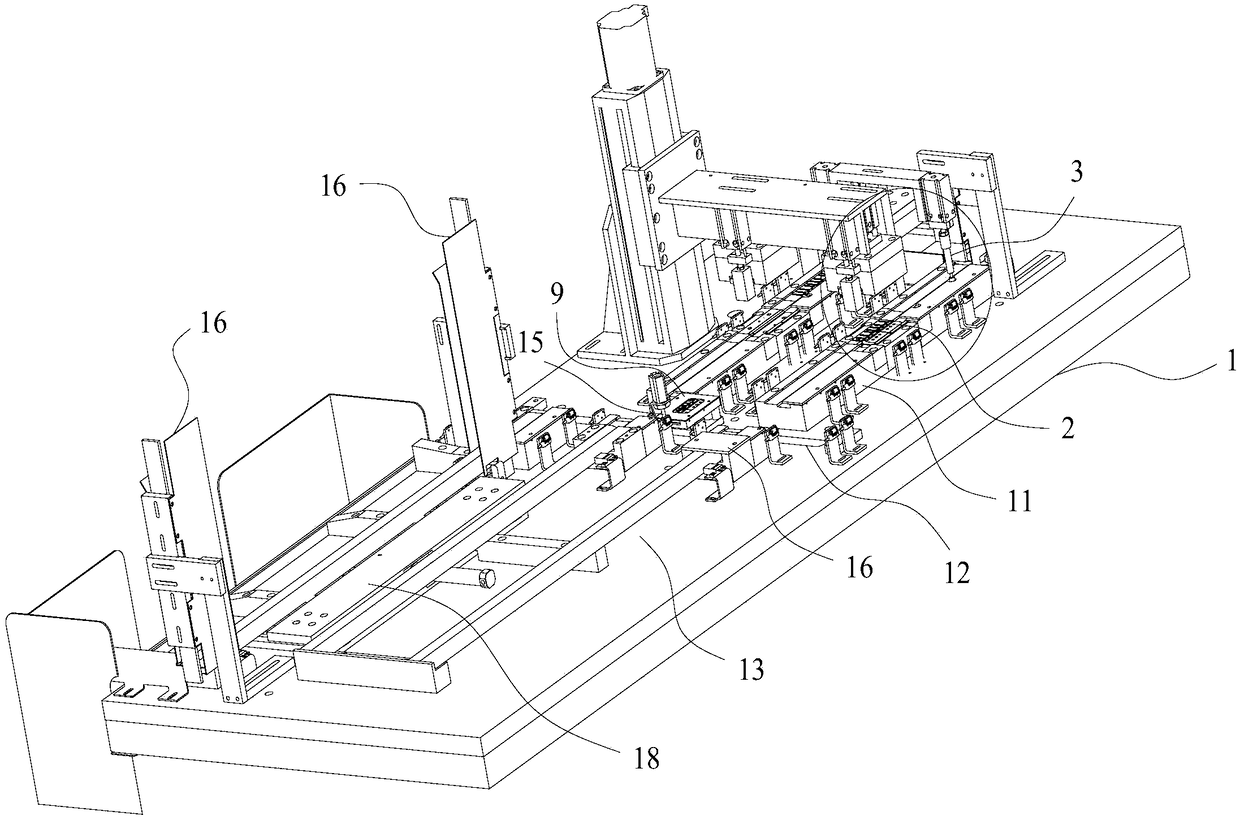

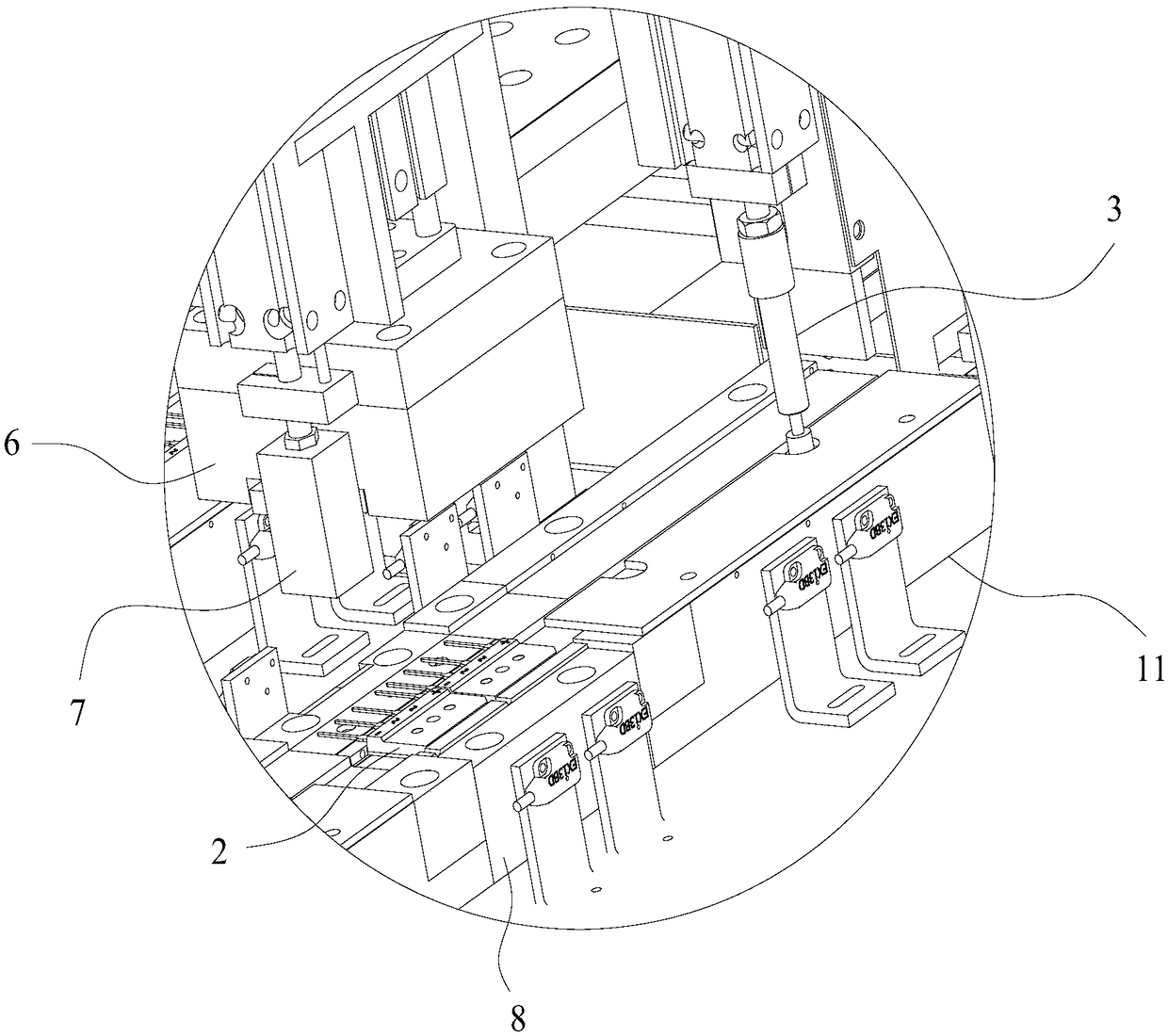

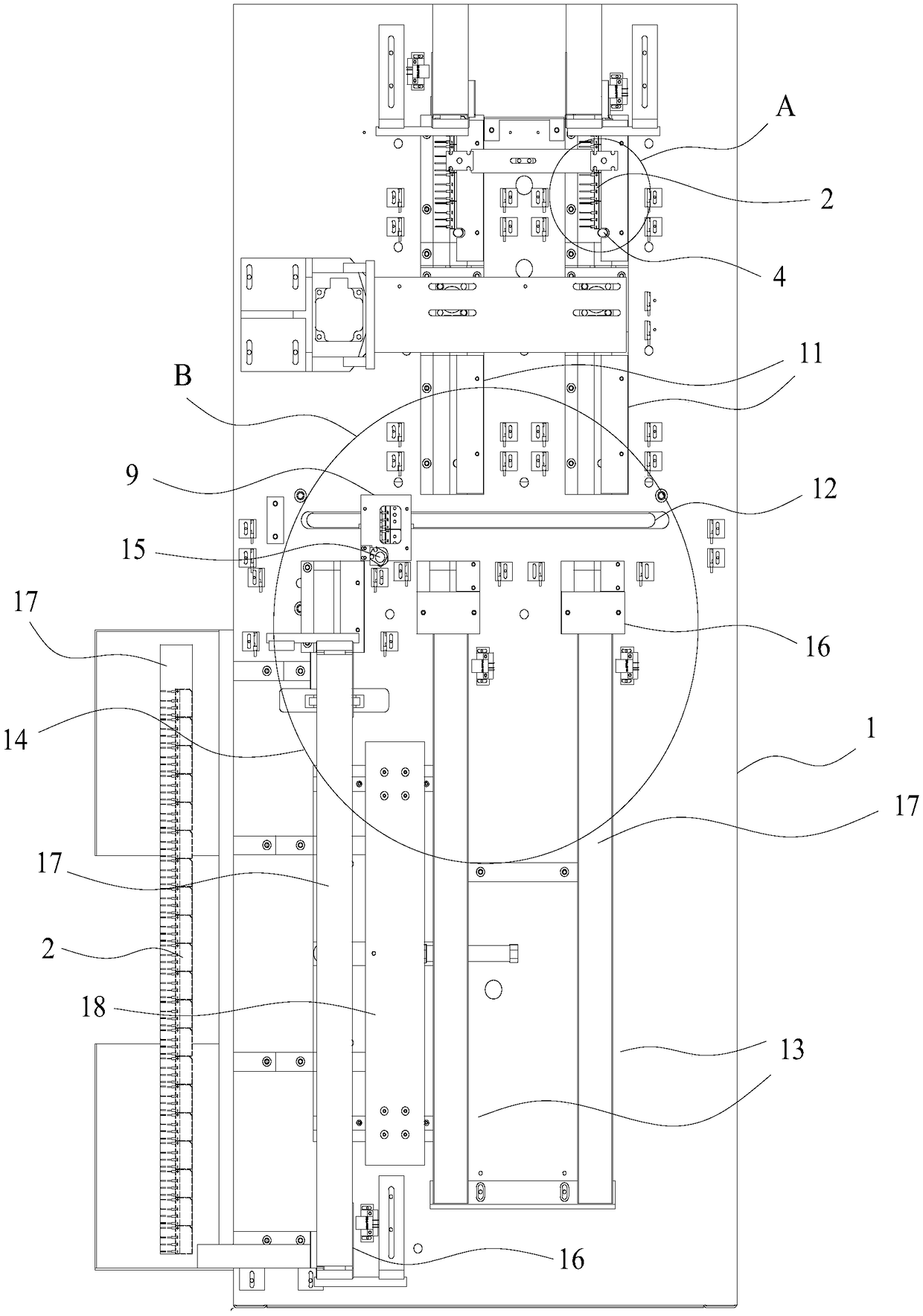

[0045] Such as Figure 1-7 As shown, a sorting device for withstand voltage test of a rectifier bridge according to the present invention includes:

[0046] Inclined surface 1, on which inclined surface 1 is provided with a slideway 11 arranged obliquely, the slideway 11 is used to place the rectifier bridge 2, and the surface shape and size of the slideway 11 are adapted to the back shape of the rectifier bridge 2 Size, the slideway 11 includes a material distribution section and a test section, the angle between the inclined surface 1 and the horizontal plane is 35°-45°, preferably 40°, and the surface of the slideway 11 is parallel to the inclined surface 1, also 40°;

[0047] The material distributing mechanism is arranged on the inclined surface 1 and is used for distributing materials to the rectifier bridge 2;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com