A method for optimizing distribution of oxygen production system in iron and steel enterprises

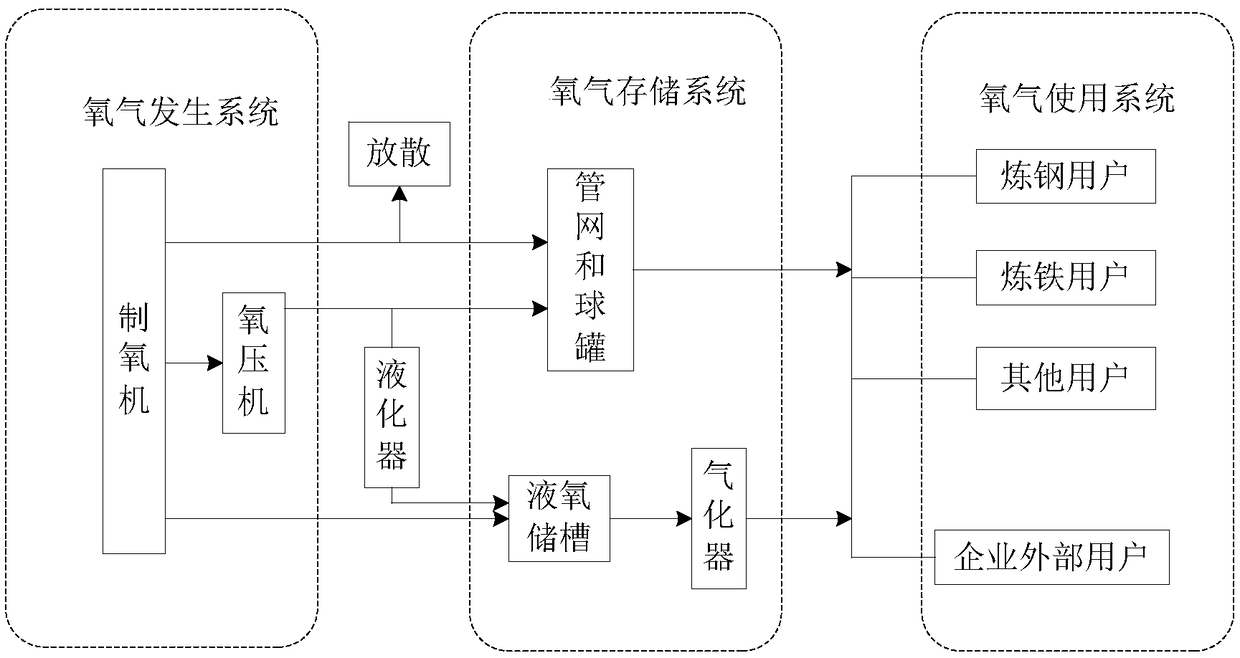

A technology for optimizing distribution and oxygen systems, applied in manufacturing computing systems, energy industry, sustainable manufacturing/processing, etc., can solve problems such as difficulty in guaranteeing safety and economy, inability to effectively consider system safety, and affecting decision-making by dispatchers. Achieve the effect of saving gas energy, strong practicability and reducing total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

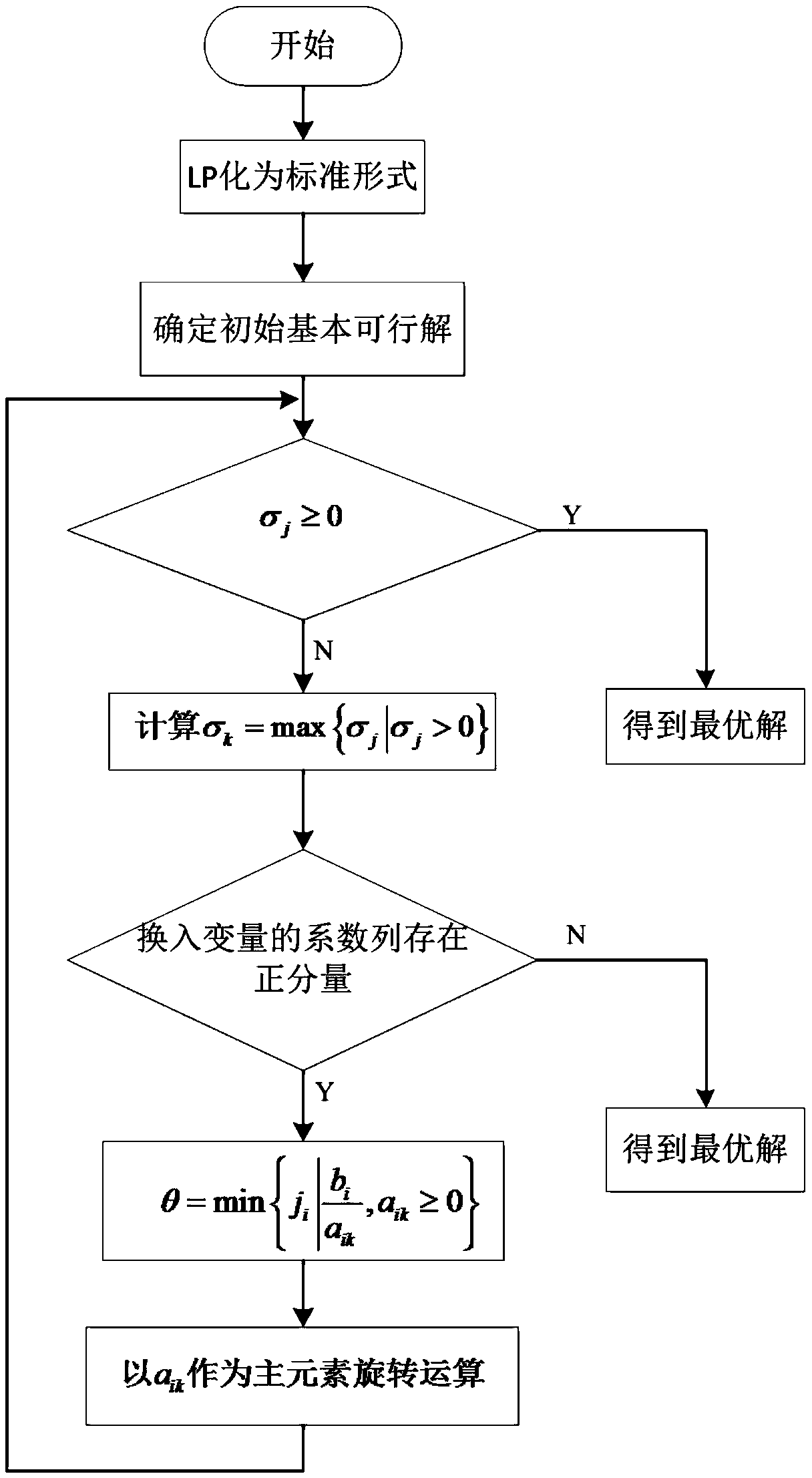

Method used

Image

Examples

Embodiment Construction

[0058] An example is given below, and the specific implementation manner of the present invention is further described in detail.

[0059] A steel company has two sets of oxygen generators, which provide low-pressure oxygen and medium-pressure oxygen. The oxygen required by the workshop is supplied by the whole plant pipe network. Flow, pressure, temperature measuring devices and filters are installed on each delivery pipeline at the entrance of the workshop. And cutting device, etc., and then sent to each user for use.

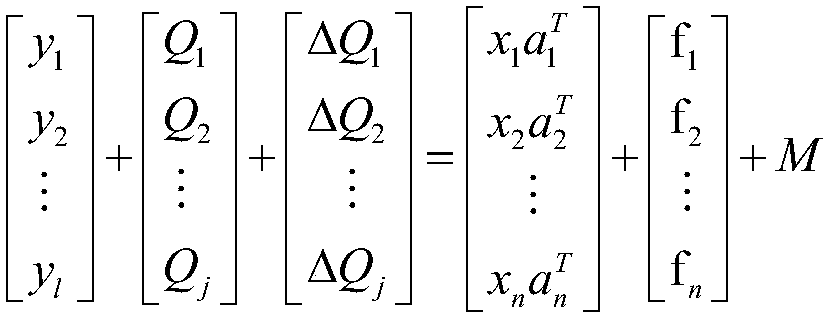

[0060] The average oxygen consumption of users in a certain period of time

[0061]

[0062] First, set the oxygen production volume y of the oxygen generator in the current period 1 =75000,y 1 =63750. When the current gas storage capacity of the oxygen spherical tank is vector 03 , △Q j = 0; when the stored oxygen in the spherical tank is higher than the maximum safe range, ΔQ j =-2000; when the stored oxygen amount of the spherical tank is lower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com