An integrated pcb board automatic entry and exit system

A PCB board, integrated technology, applied in the field of integrated PCB board automatic entry and exit systems, can solve the problems of inability to quickly assemble, high defect rate, time-consuming efficiency, etc., and achieve the effect of saving assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

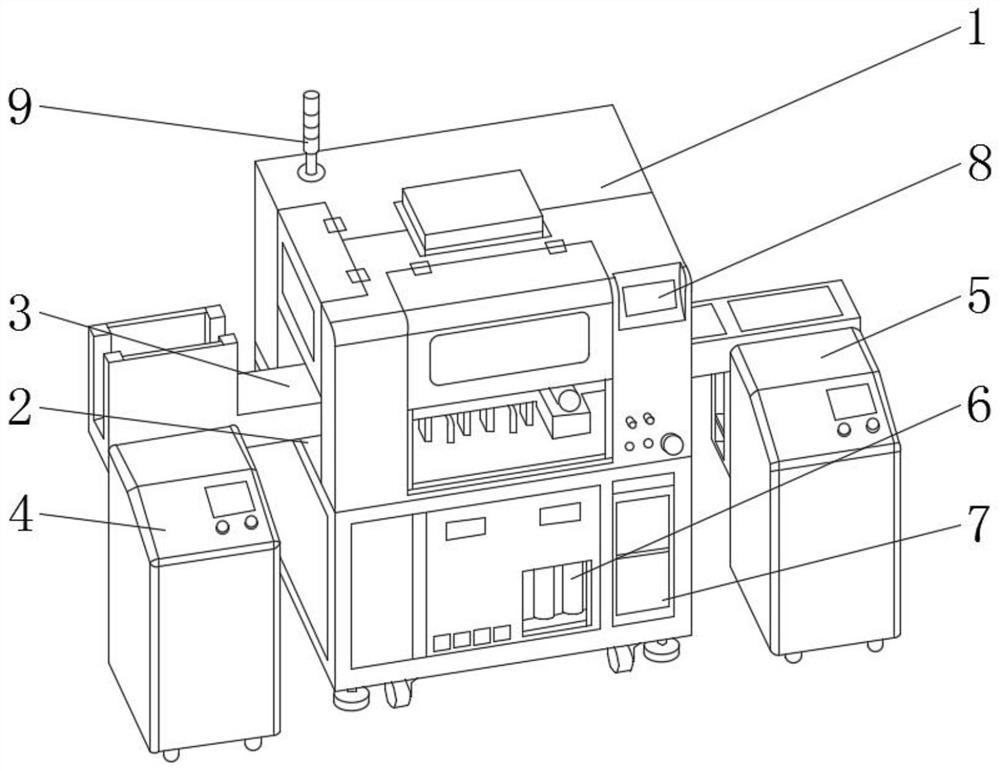

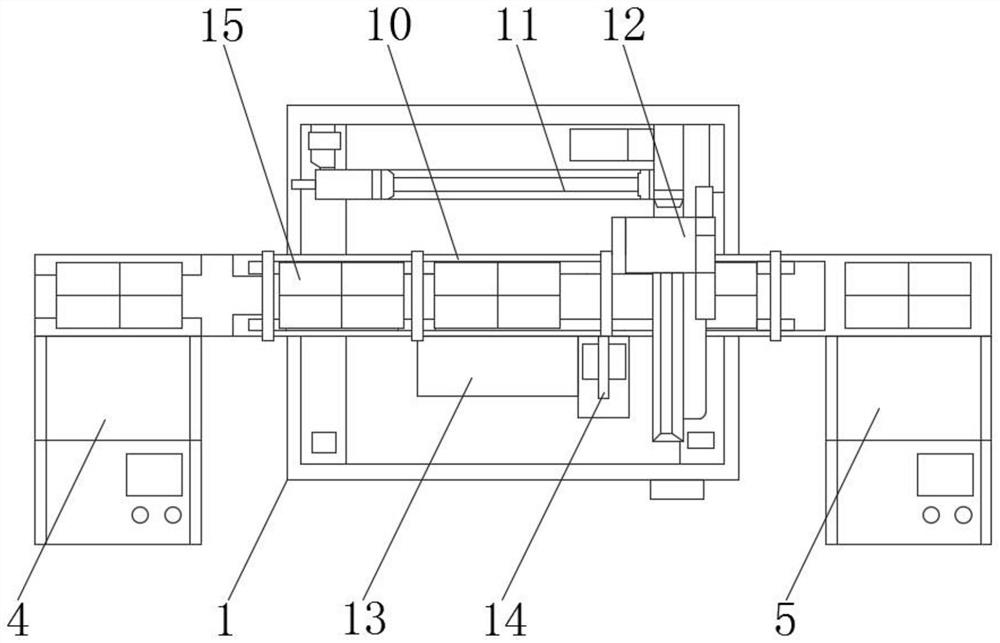

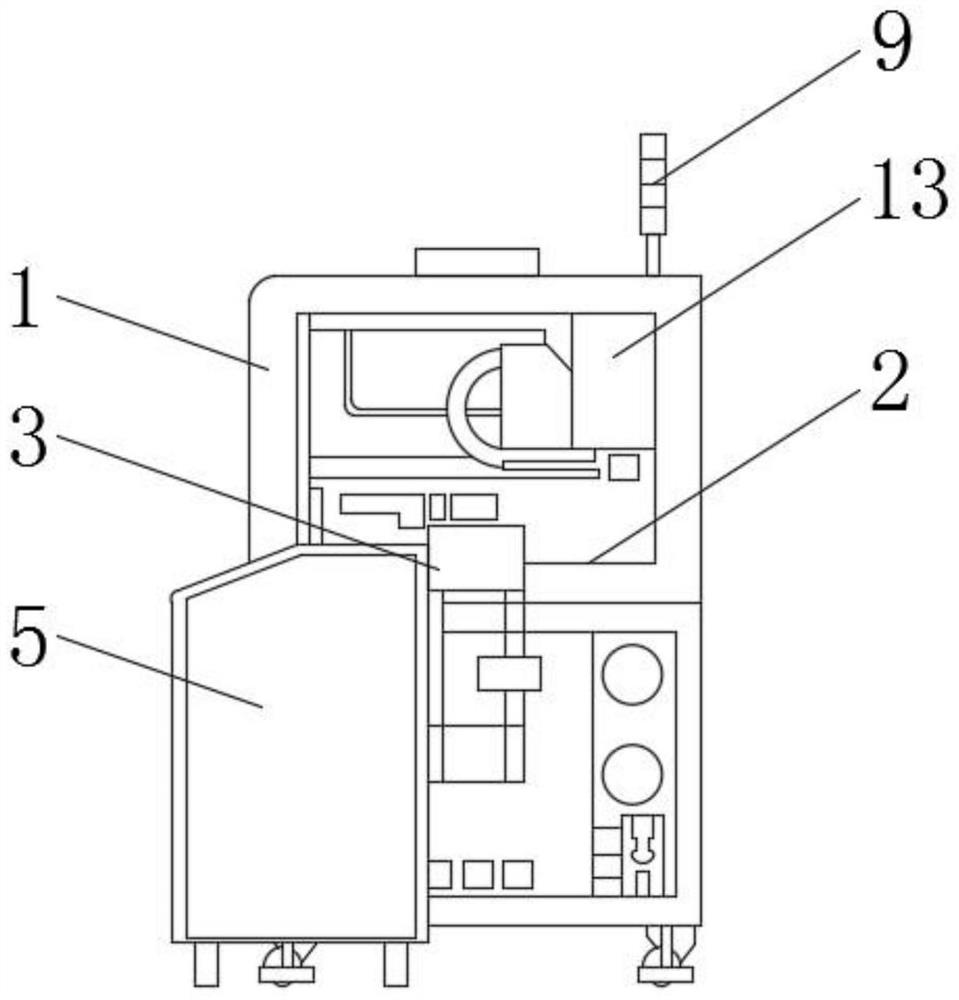

[0022] Such as Figure 1-3 As shown, an integrated PCB board automatic entry and exit system includes a main frame 1, a table panel 2 is provided through the interior of the main frame 1, a timing belt 3 is provided on the upper end of the table panel 2, and a feeding belt is provided at one end of the timing belt 3. Device 4, the other end of the synchronous belt 3 is provided with a receiving device 5, and the inside of the bottom end of the front side of the main box 1 is respectively fixed with an oil-water separator 6 and an industrial computer 7, and the oil-water separator 6 is located on one side of the industrial computer 7 A touch screen 8 is fixedly installed on one side of the upper end of the main chassis 1, a red, yellow and green alarm light 9 is fixedly installed on the outer surface of the upper end of the main chassis 1, and a connecting platform 10 and a cantilevered XY axis 11 are fixedly installed on the upper end of the table panel 2. And the connecting p...

Embodiment 2

[0024] Such as Figure 1-3 As shown, an integrated PCB board automatic entry and exit system includes a main frame 1, a table panel 2 is provided through the interior of the main frame 1, a timing belt 3 is provided on the upper end of the table panel 2, and a feeding belt is provided at one end of the timing belt 3. Device 4, the other end of the synchronous belt 3 is provided with a receiving device 5, and the inside of the bottom end of the front side of the main box 1 is respectively fixed with an oil-water separator 6 and an industrial computer 7, and the oil-water separator 6 is located on one side of the industrial computer 7 A touch screen 8 is fixedly installed on one side of the upper end of the main chassis 1, a red, yellow and green alarm light 9 is fixedly installed on the outer surface of the upper end of the main chassis 1, and a connecting platform 10 and a cantilevered XY axis 11 are fixedly installed on the upper end of the table panel 2. And the connecting p...

Embodiment 3

[0026] Such as Figure 1-3 As shown, an integrated PCB board automatic entry and exit system includes a main frame 1, a table panel 2 is provided through the interior of the main frame 1, a timing belt 3 is provided on the upper end of the table panel 2, and a feeding belt is provided at one end of the timing belt 3. Device 4, the other end of the synchronous belt 3 is provided with a receiving device 5, and the inside of the bottom end of the front side of the main box 1 is respectively fixed with an oil-water separator 6 and an industrial computer 7, and the oil-water separator 6 is located on one side of the industrial computer 7 A touch screen 8 is fixedly installed on one side of the upper end of the main chassis 1, a red, yellow and green alarm light 9 is fixedly installed on the outer surface of the upper end of the main chassis 1, and a connecting platform 10 and a cantilevered XY axis 11 are fixedly installed on the upper end of the table panel 2. And the connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com