Automatic sorting system for customization of furniture plates

A sorting system and board technology, applied in sorting and other directions, can solve the problems of high work intensity, matching efficiency, and high labor cost of sorting personnel, and achieve rapid transmission and transfer, prevent missing and misplaced, and facilitate transmission The effect of docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

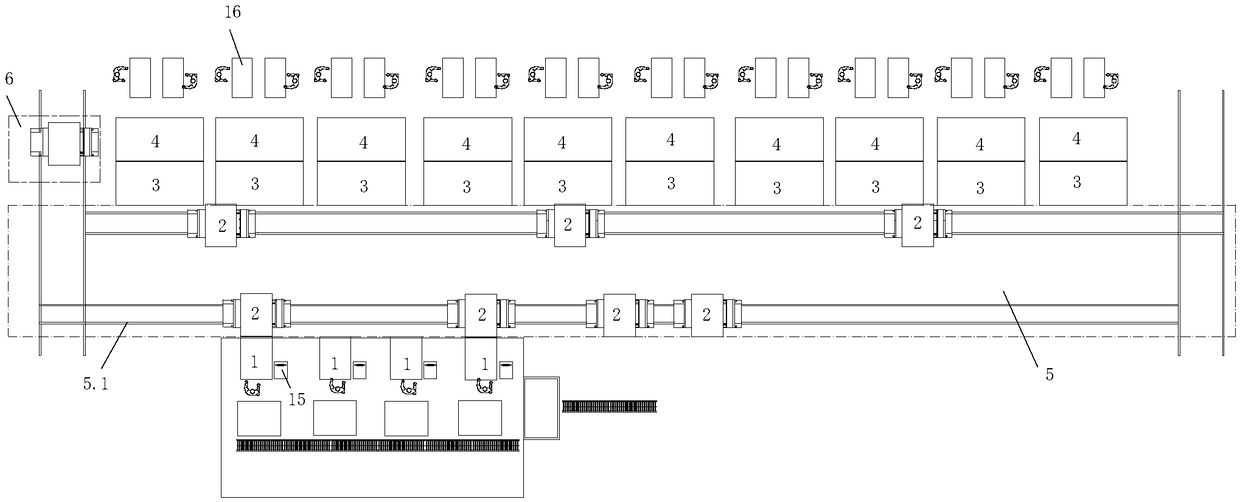

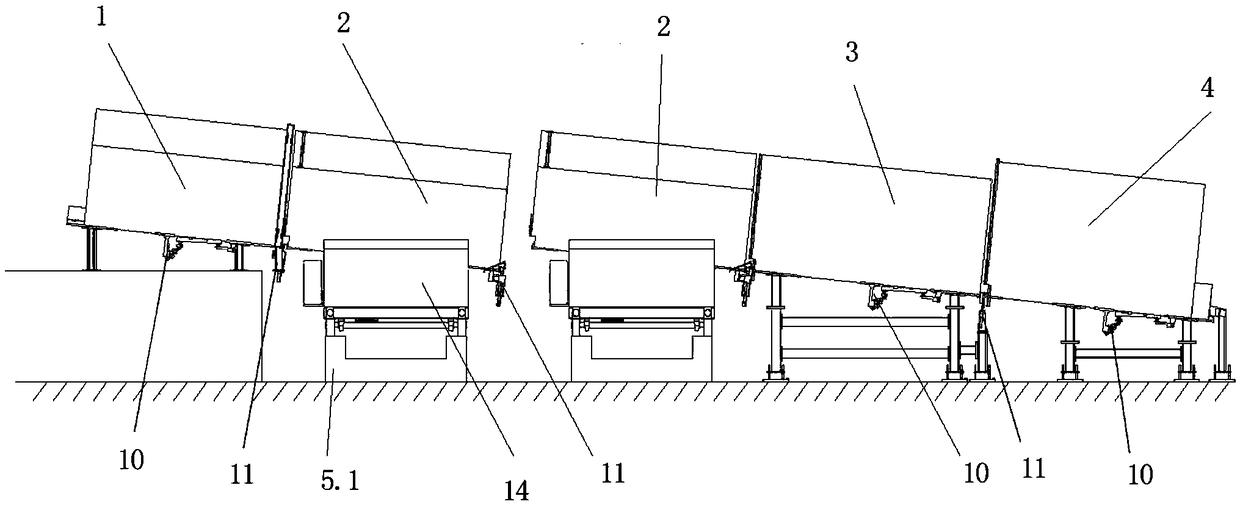

[0052] An automatic sorting system for customizing furniture panels in this embodiment, its structure is as follows: Figure 1 to Figure 14 shown; includes:

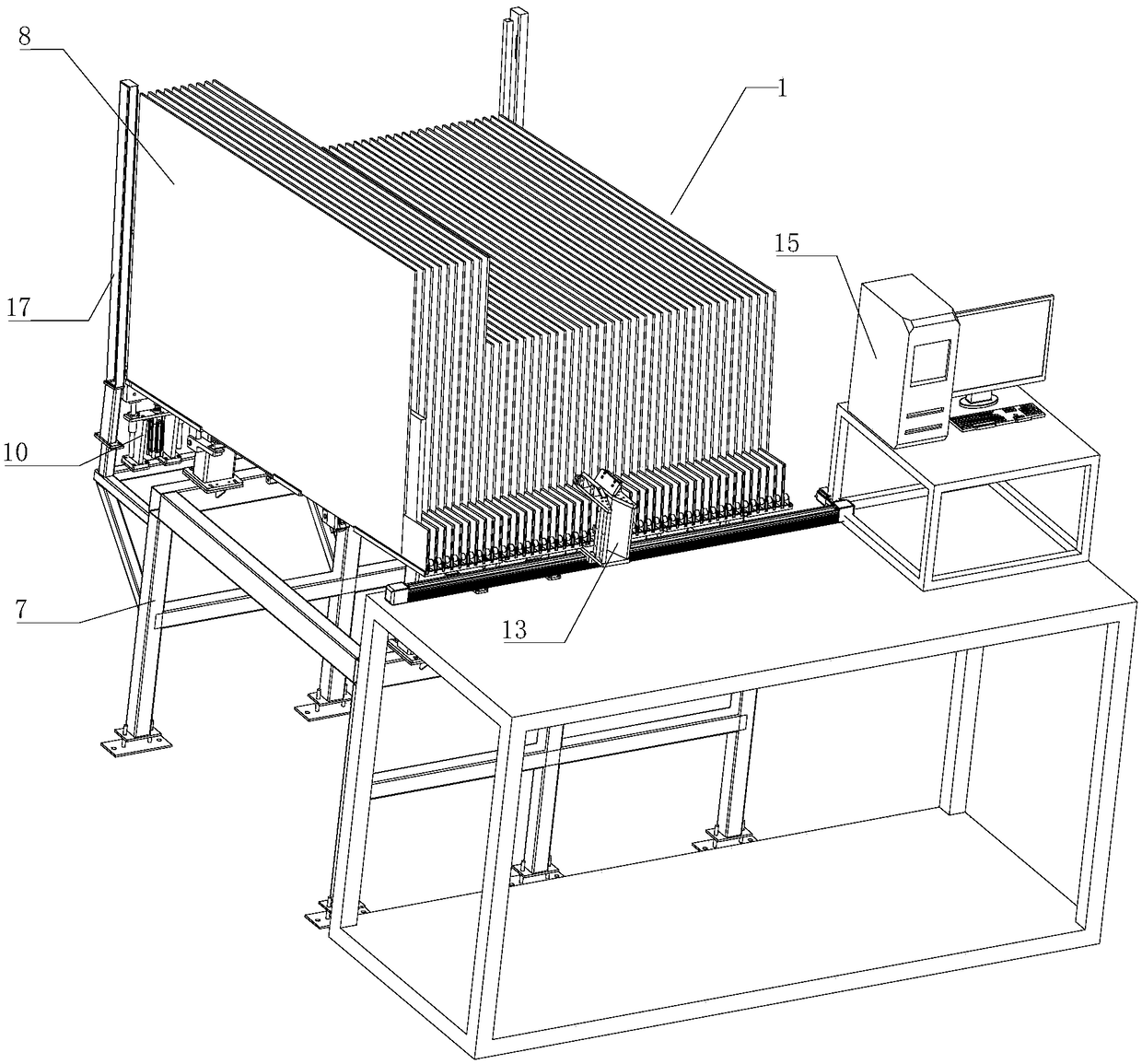

[0053] A feeding device 1 for storing the boards upright, side by side, independently, and transferring the boards to the outlet side;

[0054] It is used to receive the boards delivered by the feeding device 1 and store the boards upright, side by side and independently, and move the carrying boards to move the boards one by one to the preset space position to be entered and move the boards to the exit side The transmitted mobile device 2;

[0055] A sorting device 3 for receiving the boards delivered by the mobile device 2 and storing the boards upright, side by side and independently, and transferring the boards to the exit side;

[0056] And a discharge device 4 for receiving the plates delivered by the sorting device 3 and storing the plates upright, side by side, and independently.

[0057] The feeding device 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com